CRYOMAGNETICS LM-510 Instruction Manual

LM-510 Operating Instruction Manual –Revision 1.3

1006 Alvin Weinberg Drive

Oak Ridge, Tennessee 37830

Phone: (865) 482-9551 Fax: (865) 483-1253

Web: http://www.cryomagnetics.com

WARNING!

DO NOT ATTEMPT TO OPERATE THIS EQUIPMENT BEFORE YOU

HAVE THOROUGHLY READ THIS INSTRUCTION MANUAL.

OPERATING INSTRUCTION MANUAL

FOR THE

MODEL LM-510

LIQUID CRYOGEN

LEVEL MONITOR

CE

MANUFACTURER'S DECLARATION OF CONFORMITY

According to lSO / IEC Guide 22 and EN45014

Manufacturer's Name: Cryomagnetics, Inc.

Manufacturer's Address: 1006 Alvin Weinberg Drive

Oak Ridge, TN 37830

Declares. the product

Product Name: Liquid Cryogen Level Monitor

Model Number: LM-510

Product Options: All Options

Conforms to the following Product Specifications:

Safety: EN61010-1 (95)

EN61326-1 (97)

EMC: EN61326-1 (97) Electrical Equipment for Measurement,

Control and Lab use –EMC Requirements

EN61000-4-2 (95) Electrostatic Discharge Immunity Test

EN61000-4-3 (96) Radiated Electromagnetic Fields

EN61000-4-4 (95) Electrical Fast Transient/Burst

EN61000-4-5 (95) Amendment A-Surge Immunity Test

EN61000-4-6 (96) Amendment A-Immunity to Conducted

Disturbances

EN61000-4-11 (94) Voltage Dips, Short Interruptions and

Voltage Variations

Application of Council Directives:

The product complies with the requirements of the Low Voltage Directive

73/23/EEC as amended by 93/68/EEC and the EMC Directive 89/336/EEC as

amended by 93/68/EEC.

D. Michael Coffey, President

Cryomagnetics, Inc

Oak Ridge Tennessee August 22, 2012

LM-510 Operating Instruction Manual –Revision 1.3

i

Table of Contents

1.0 Introduction ......................................................................................................... 1

2.0 Factory Calibrations, Installed Options and Certification ....................................... 5

3.0 Instrument Setup and Sensor Connection ............................................................. 7

3.1 Line Voltage and Fuse ..................................................................................................... 7

3.2 Connecting Sensors, Relay functions, and Analog Outputs ............................................... 7

4.0 Operation and Menus......................................................................................... 11

4.1 Menu Organization ....................................................................................................... 12

4.2 Liquid Helium Level Channel.......................................................................................... 14

4.2.1 Mode................................................................................................................................. 14

4.2.2 Alarm Set Points................................................................................................................ 14

4.2.3 Control Mode.................................................................................................................... 15

4.2.4 Units................................................................................................................................. 15

4.2.5 Boost................................................................................................................................. 15

4.2.6 Sensor Active Length......................................................................................................... 16

4.2.7 Lead Resistance................................................................................................................. 16

4.2.8 Ohms per CM .................................................................................................................... 16

4.3 Liquid Nitrogen (Capacitive) Level Channel .................................................................... 16

4.3.1 Alarm Set Points................................................................................................................ 17

4.3.2 Control Mode.................................................................................................................... 17

4.3.3 Units................................................................................................................................. 18

4.3.4 Sensor Active Length......................................................................................................... 18

4.3.5 Offset / Gain...................................................................................................................... 18

4.4 Setup Menu.................................................................................................................. 19

4.5 Advanced Menu –Firmware Updates and LN2 Sensor Configuration .............................. 20

4.5.1 LN2 Sensor Configuration ................................................................................................. 20

4.5.2 Firmware Update .............................................................................................................. 21

5.0 Control Interfacing ............................................................................................. 23

5.1 Analog Output .............................................................................................................. 23

5.2 Automatic Refill ............................................................................................................ 23

5.3 Using Ctrl as an Alarm ................................................................................................... 26

6.0 Theory of Operation ........................................................................................... 27

6.1 Liquid Helium Level Sensing (Superconductive Filament Probes) .................................... 27

6.2 Liquid Nitrogen Level Sensing (Capacitive Probes).......................................................... 28

6.3 LM-510 Circuit Description ............................................................................................ 29

7.0 Limited Warranty Policy ..................................................................................... 31

Appendix A - Computer Interface Command Reference................................................. 33

Appendix B - Line Voltage Controller Module –Option 4 ............................................... 52

Appendix C - Factory Calibration / Firmware Updates.................................................... 53

Liquid Helium Channels.............................................................................................................. 53

LM-510 Operating Instruction Manual –Revision 1.3

ii

Liquid Nitrogen Channels........................................................................................................... 53

Firmware Updates...................................................................................................................... 53

Appendix D –Updated LN2 Probe Notes....................................................................... 54

1. Calibrate empty level .................................................................................................... 54

2. Calibrate full level ......................................................................................................... 54

Appendix E - Helium Recondenser Controller Option..................................................... 55

List of Figures -

Figure 1 - LM-510 / Dual Channel LHe-LN2 ....................................................................................... 1

Figure 2 - LM-510 Rear Panel............................................................................................................. 7

Figure 3 - LHe Level Sensor Connector Wiring .................................................................................. 7

Figure 4 - LN2 Level Sensor Connector Wiring .................................................................................. 8

Figure 5 - Auxiliary Connector Wiring - DB-9F.................................................................................... 9

Figure 6 - Front Panel Display........................................................................................................... 11

Figure 7 - LM-510 Menu Hierarchy ................................................................................................... 13

Figure 8 - LHe Channel Menu...........................................................................................................14

Figure 9 - Liquid Nitrogen Channel Menu.........................................................................................17

Figure 10 - Setup Menu.....................................................................................................................19

Figure 11 - LN2 Sensor Configuration Menu .................................................................................... 20

Figure 12 - Firmware Update Menu ..................................................................................................21

Figure 13 - Typical Automatic Cryogen Refill System.......................................................................24

LM-510 Operating Instruction Manual –Revision 1.3

1

1.0 Introduction

The LM-510 Liquid Cryogen Level Monitor is the most advanced instrument for monitoring and

controlling cryogenic liquids available today. Its versatile architecture allows configuration to

virtually any cryogenic fluid including liquid helium, liquid nitrogen, LNG, LOX and many others.

Figure 1 - LM-510 / Dual Channel LHe-LN2

The LM-510 is available in single channel or two-channel versions. With the two-channel option the

instrument has two independent input channels that are factory configurable to either the same or

different liquid types. The unit is compatible with liquid helium level sensors based upon industry

standard niobium-titanium superconducting elements. Virtually all liquid helium sensor

manufacturers use this technology, so the LM-510 can be used with most existing equipment.

Flexible calibration procedures allow the use of two, three, or four wire configured liquid helium

sensors.

Capacitive sensors are used to monitor liquid nitrogen, LNG and other cryogenic fluids. As with

liquid helium sensors, the LM-510 can monitor many manufacturers’ capacitive sensors due to

advanced circuit design.

The LM-510 has user-adjustable high and low set points that may be used to control automated

refill cycles. With the two-channel option, independent set points can be adjusted for each channel.

This allows simultaneous control of two liquid cryogen systems with a single LM-510.

Also included are fully adjustable alarms for each channel. Most commonly set below the low

control set point, the alarm can be used to alert the user (audibly and visually) to a problem with the

refill cycle, and to automatically take action (relay contacts are provided).

LM-510 Operating Instruction Manual –Revision 1.3

2

Unique features of the LM-510 include a sensor deicing cycle and filament burnout protection for

liquid helium systems. This insures reliable, accurate level readings even under the most adverse

cryogenic conditions.

Computer control of the LM-510 is possible via USB and Ethernet interfaces –both are provided in

the standard configuration. IEEE-488 and RS-232 interfaces are available as options. LabVIEW®

virtual instrument drivers are available to allow computer control via a familiar, intuitive interface. A

wide variety of other options are also available that allow the instrument to be upgraded and tailored

to your particular requirements.

LM-510 Operating Instruction Manual –Revision 1.3

3

Specifications

Common Specifications

Display Update Rate: ~ 500ms Intervals

Control/ Alarm Relay Voltage Rating 100V

Control/ Alarm Relay Current Rating 135mA

12V Loop Source 25mA maximum

4-20mA Analog Output Loop Power 24V maximum

0-10V Analog Output 1 mA maximum

AC Input: 100-240V a.c., 50-60 Hz, 30 Watts

Operating Temperature: 15 C to 35 C

Relative Humidity 10% to 95%, non-condensing

Overall Dimensions: 185 mm W X 67 mm H X 197 mm D

Weight: 1.0 kg

USB interface: USB 1.1/2.0 Full-Speed

IEEE-488 interface: IEEE-488.2-1992 Standard

Ethernet: IEEE-802.3 10/100 BASE-T

Liquid Helium Channel Specifications

Maximum Sensor Length: 200 cm

Measurement Resolution 0.1 cm or 0.1 percent of sensor length

Measurement Accuracy +/- 0.5% FS

Liquid Nitrogen Channel Specifications

Maximum Sensor Capacitance: 2000 picofarads

Measurement Resolution 0.1 cm or 0.1 percent of sensor length

Measurement Accuracy +/- 1.0% of calibrated range

Model Configurations

LM-510-10 Single Channel Liquid Helium

LM-510-11 Dual Channel Liquid Helium

LM-510-20 Single Channel Liquid Nitrogen

LM-510-22 Dual Channel Liquid Nitrogen

LM-510-12 Dual Channel Liquid Helium/Liquid Nitrogen

Optional Equipment

LM-510-xx-1 IEEE-488 Interface

LM-510-xx-2 RS-232 Interface

LM-510-xx-3 19” Rack Mountable Cabinet

LM-510-xx-4 Line Voltage Controller Output

The LM-510 is designed to operate per the specifications in this table and the instructions provided in this

manual. Other use may impair the safety protections provided by the equipment.

LM-510 Operating Instruction Manual –Revision 1.3

4

This Page Intentionally Left Blank

LM-510 Operating Instruction Manual –Revision 1.3

5

2.0 Factory Calibrations, Installed Options and Certification

LM-510 Serial Number:

Input Channel 1:

Type: LHe LN2 Other:

Calibration: Sensor Manufacturer / Serial No:

Sensor Length:

Characteristic Resistance/Voltage:

Lead Resistance:

Input Channel 2: Not Installed:

Type: LHe LN2 Other:

Calibration: Sensor Manufacturer / Serial No:

Sensor Length:

Characteristic Resistance/Voltage:

Lead Resistance:

Computer Interface Installed: IEEE-488.2 (Option 1) : RS-232(Option 2):

Notes:

Certified:

Date:

LM-510 Operating Instruction Manual –Revision 1.3

6

This Page Intentionally Left Blank

LM-510 Operating Instruction Manual –Revision 1.3

7

3.0 Instrument Setup and Sensor Connection

The LM-510 is delivered to you fully tested and ready to operate. This includes sensor calibration if

Cryomagnetics supplied the sensor(s) with the instrument. Calibration will also be complete if the

active sensing length of an existing sensor(s) was specified at the time of order.

Figure 2 - LM-510 Rear Panel

3.1 Line Voltage and Fuse

The LM-510 is designed to operate with any AC power source between 100V and 240V A.C. and 50

to 60 Hz. No user serviceable fuse is provided.

3.2 Connecting Sensors, Relay functions, and Analog Outputs

Sensors connect to the LM-510 at the rear panel using circular connectors located above the labels

‘Channel 1’ and ‘Channel 2’. Figure 3 indicates the pin designations for the Liquid Helium Sensor

connectors.

(Rear LM-510 view)

Pin # Lead Function Teflon Color Phosphor-Bronze Color

1 I+Red Clear

2 V+Blue Yellow

3 Shield N/A N/A

4 V−Yellow Green

5 I−Black Black

Figure 3 - LHe Level Sensor Connector Wiring

1

2

3

4

5

LM-510 Operating Instruction Manual –Revision 1.3

8

The Liquid Nitrogen Level sensor connections are shown in Figure 4.

(Rear LM-510 view)

Pin # Lead Function Wire Color

1 V+ (10.6V) Red

2 Data White

3 Gnd Black

4 Shield N/A

Figure 4 - LN2 Level Sensor Connector Wiring

********** IMPORTANT ***********

1) Connections should NEVER be made directly to the connector on the rear panel. Always

solder to a mating connector that is not attached to the unit. Connections should be double-

checked for accuracy prior to attaching to the LM-510 and powering the unit ON since liquid

helium level sensors are driven by high voltages (up to 70 volts DC). These high voltages

could damage liquid nitrogen sensors or other sensors (such as temperature sensors or hall

probes) should these be accidentally connected.

2) NEVER connect/disconnect the sensors with the LM-510 powered ON.

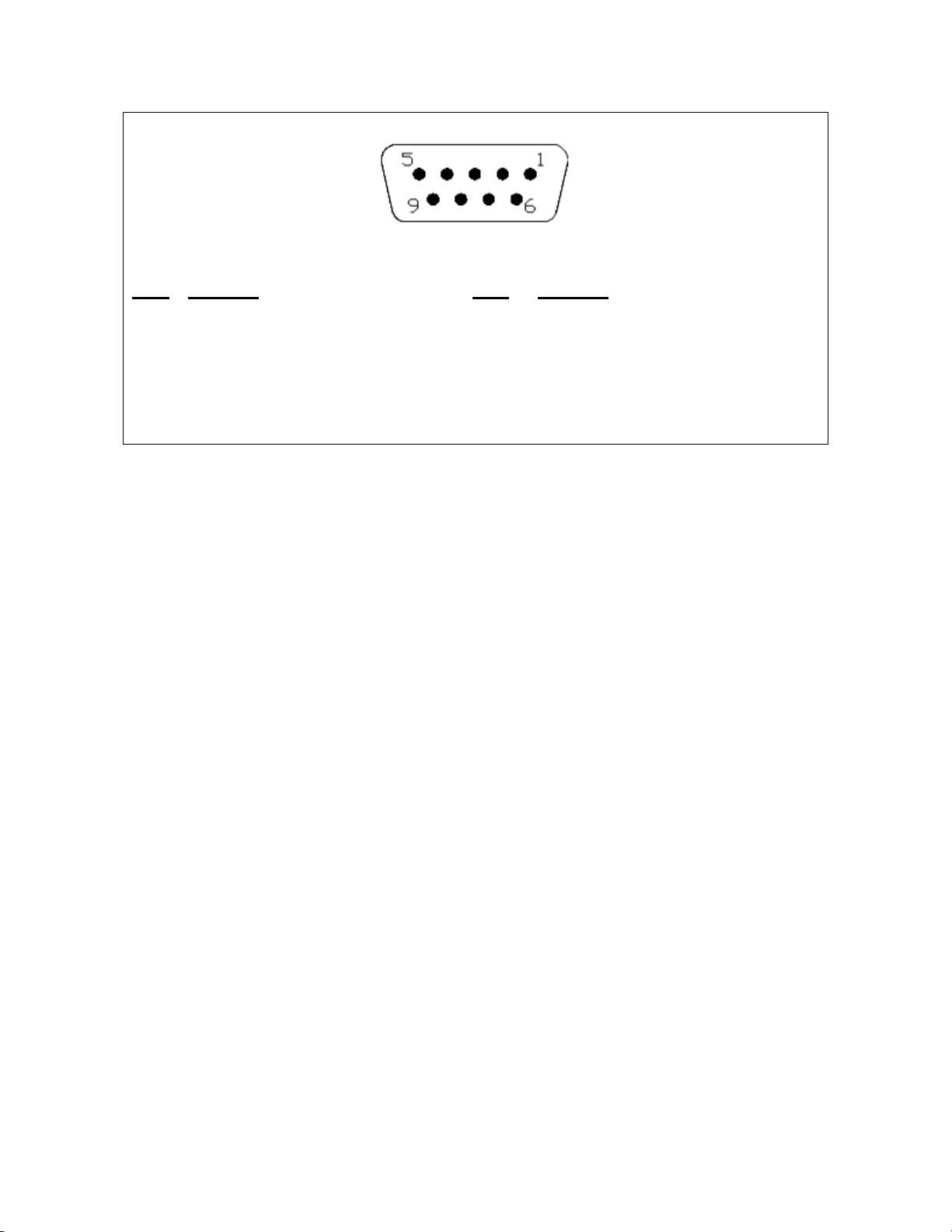

Each input channel of the LM-510 also has a dedicated auxiliary DB-9F connector. This connector

provides access to the automatic refill (control) relay and alarm relay functions, the 4-20mA analog

output signal, and the 0-10V analog output signal. There is also a 12V output that may be used to

power the 4-20mA analog output current loop. Figure 5 indicates the pin designations for the

auxiliary connector.

1

4

3

2

LM-510 Operating Instruction Manual –Revision 1.3

9

View Facing Rear Panel Connector

Pin # Function: Pin # Function:

1 Control Relay –Contact A (NO) 6 Control Relay –Contact B (NO)

2 Alarm Relay –Contact A (NO) 7 Alarm Relay –Contact B (NO)

3 0-10V Analog Output 8 4-20mA Loop Power In

4 4-20mA Analog Output 9 12V Loop Power Out (25mA max)

5 Analog Ground

Figure 5 - Auxiliary Connector Wiring - DB-9F

Cryomagnetics’liquid helium level sensors have four (4) lead wires and use either #30 AWG Teflon

insulated lead wires or color coded phosphor-bronze lead wires (either option may be specified

when the sensor is ordered). The connector pin connections and standard color codes for lead

wires are shown in Figure 3.

Some liquid helium level sensors made by Cryomagnetics may have only 2 or 3 lead wires. If the

sensor has 3 lead wires, the I- and V- leads are typically combined into a single black lead. If the

sensor has 2 lead wires, the I- and V- leads are combined into a single black lead and the V+ lead

is not used. The V+ connection at the input to the LM-510 should be connected to the I+ terminal in

this case.

Cabling between the liquid helium level sensor and the LM-510 should be of appropriate size such

that high voltage drop across the I+ and I- leads does not occur. It is recommended that cables up

to 5 meters in length be #18 AWG wire minimum. Cables from 5 to 15 meters in length should be

#16 AWG minimum, and cables from 15 to 30 meters should be #14 AWG minimum. Unshielded

cable may be used where no significant use of SCR-controlled equipment or intense electrostatic

field sources are present. Otherwise, it is recommended that shielded cable be used.

LM-510 Operating Instruction Manual –Revision 1.3

10

This Page Intentionally Left Blank

LM-510 Operating Instruction Manual –Revision 1.3

11

4.0 Operation and Menus

Setup of the LM-510 can be performed either through the front panel keypad and simple menu

instructions or through remote computer interface (USB, Ethernet or IEEE-488.2). Sensor set up

and calibration is only supported through the front panel keypad. The following sections contain

detailed descriptions of how to set up different sensor types and lengths, adjust alarms, and

configure the controller functions.

Before connecting any level sensors or other cabling to the LM-510, connect the power cord

provided with your LM-510 to an appropriate power source. Power the instrument ON and

familiarize yourself with the display. If your LM-510 is configured for dual sensor inputs, the top half

of the display will indicate Sensor #1 and the bottom half will indicate Sensor #2. If your LM-510 is

configured for a single sensor input, the display will only indicate one level.

Figure 6 - Front Panel Display

To the right of the liquid level reading is a bar-graph indication of liquid level. The bar-graph is color

coded to give a quick visual indication of system status.

The bar graph has two horizontal blue lines that indicate the automatic control set points that have

been entered. So for instance if you want to configure the LM-510 to automatically refill a cryostat

when the liquid level drops to 10% and turn off the fill when it reaches 90%, these values can be set

in the “Ctrl Low” and “Ctrl High” menu settings. Horizontal blue lines on the bar-graph show these

LM-510 Operating Instruction Manual –Revision 1.3

12

set points.

Similarly alarm high and low set points may be entered in the LM-510. These set points are shown

on the bar-graph with a red caret symbol. Setting the high alarm at 100% and the low alarm at 0%

removes the caret symbol from the display.

A liquid helium level channel may indicate "Open Sensor" or "Burnout Protect" instead of a level.

Open sensor is self-explanatory. If no sensor is attached to the LM-510 or if a connection is broken

the unit will display the error message and will disable the output to prevent high voltages from

being present on the sensor wires. If the LM-510 is in Continuous mode, the sensor will be

reactivated every 10 seconds to see if the connection has been fixed. If the LM-510 is in Sample-

and-Hold mode, the sensor will be reactivated at the normal sample interval.

Burnout Protect is displayed if the LM-510 detects a sensor resistance runaway condition (a

resistance more than 130% of the expected resistance of the sensor in gas and at room

temperature). This condition may occur if the user attempts to activate the sensor while it is in a

vacuum. Burnout protect is activated to reduce the chance of damaging the sensor. If Burnout

Protect is activated, the sensor will be deactivated and the error message displayed. As with Open

Sensor described above, if the LM-510 is in Continuous mode, the sensor will be reactivated every

30 seconds to see if the condition has been resolved. If the LM-510 is in Sample-and-Hold mode,

the sensor will be reactivated at the normal sample interval.

If the LM-510 is operating in sample/hold mode with a liquid helium level sensor, the top line of the

display will show a timer that indicates how long ago the displayed reading was taken. The interval

between readings may be adjusted (see section 4.2.1 below). If the user wants to update the

display without changing the sample interval, simply press <ENTER> and the instrument will take

new liquid helium level readings.

4.1 Menu Organization

The menus of the LM-510 are designed to minimize the number of keystrokes required, while at the

same time being intuitive for system operators. The level monitor menu options are accessed by

pressing the “Menu” button on the keypad and using the ◄► keys to highlight the desired channel

tab. General instrument setup options are accessed by highlighting the Setup tab.

LM-510 Operating Instruction Manual –Revision 1.3

13

Figure 7 - LM-510 Menu Hierarchy

Chan 1

(LHe Example)

Mode

•Continuous

•Sample/Hold

•Time Interval

•Disabled

Alarm Lo

Alarm Hi

Control Low

Control High

Control Mode

•Auto

•Manual

•Off

Timeout

Units

•Centimeters

•Inches

•Percent

Boost

•Off

•On

•Smart

Sensor Length

Lead Resistance

Ohms per CM

Chan 2

(LN2 Example)

Alarm Lo

Alarm Hi

Control Low

Control High

Control Mode

•Auto

•Manual

•Off

Timeout

Units

•Centimeters

•Inches

•Percent

Sensor Length

Zero Offset

Gain

Setup

Interface

•USB

•LAN

•GPIB

•RS-232

Baud Rate

GPIB ID

IP Address

Subnet

Gateway

MAC Address

Socket

Audio Alarm

LM-510 Operating Instruction Manual –Revision 1.3

14

4.2 Liquid Helium Level Channel

To set up a liquid helium level sensor, power ON the LM-510 and press the MENU key. Use the

◄► keys to select the appropriate sensor channel tab at the top of the display, then the ▲▼ keys

to select the sensor parameter to be calibrated. There are several user-adjustable options available

for liquid helium level monitoring. The above diagram indicates options and the menu headings

under which they are found. A description of the menu items is outlined below.

Figure 8 - LHe Channel Menu

4.2.1 Mode

In the Mode menu item the user can select Sample/Hold, Continuous or Off. This item appears first

in the menu list since it may be changed frequently in a system that is left in Sample/Hold mode

normally, but is switched to Continuous mode during liquid helium refills. Pressing ENTER while

“Mode” is selected toggles the unit between Sample/Hold, Continuous, and Off modes. The display

will indicate the selected mode.

While in Sample/Hold mode, an interval of time between readings of the liquid helium level sensor

in Sample/Hold mode can be specified. With Sample/Hold selected, press ►or ▼to highlight the

interval setting display. Then use the keypad keys to enter the sample interval to the desired time

in hours, minutes, and seconds, separating each with a “.” (decimal point).

4.2.2 Alarm Set Points

The LM-510 has alarm set points that may be used to alert the operator when the LHe level falls

Table of contents

Other CRYOMAGNETICS Measuring Instrument manuals