Cryotherm BIOSAFE 120 User manual

Operating Manual

BIOSAFE® 120 / 220 / 420 MDß

Service – Hotline:

+49 (0) 2741-95 85 75

Inhalt

I

Seite

1Introduction 1

1.1Symbols in the Manual 1

1.2Principle 2

1.3Delivery 2

2Component Overview 3

3Cryogenic Storage Vessels

CHRONOS®120/220/420 4

3.1Specifications of the Vessels CHRONOS®

120/220/420 4

3.2Structure of the Vessel 6

3.2.1Combined Positive Pressure Relief and Seal-off

Device 6

3.2.2Castors / Transport possibilities CHRONOS®120 7

3.2.3Castors / Transport possibilities CHRONOS®

220/420 8

3.2.4Cover CHRONOS® 120 9

3.2.5Cover / Elevating Mechanism CHRONOS®

220/420 10

3.2.6Storage Shelf / Storage Frame 12

3.2.7Connection for Level Control Unit and Vessel

Control System BIOSAFE – CONTROL® ß 12

3.2.8Fill Connection 13

4Level Control Unit and Vessel Control System

BIOSAFE-CONTROL®ß 14

4.1Functions 14

4.2Operating Elements 23

4.3Assembly / Commissioning 24

4.4Normal Operation 24

5Safety 26

5.1Safety advices 26

5.2How to handle liquid Nitrogen 26

5.3General Safety Instructions 26

5.4Proper Use according to the Regulations 26

5.1Safety Safety advices “Handling with cryogenic

liquefied gases” Source: IGV Germany 27

5.2Note Road Transportation 31

5.3Labelling 32

6Transport and Assembly 33

6.1General Transport 33

6.2Assembly 34

7Operation 35

7.1Installation / Assembly 35

7.1.1Assembly of the Fill Line 35

7.1.2Assembly of BIOSAFE-CONTROL®ß 36

7.1.3Connection of the liquid Nitrogen Supply 36

7.2Initial Commissioning 37

7.3Normal Operation 38

7.4Storing and Taking-out of Samples 40

7.5Putting out of Operation / Cleaning 41

Contents

Introduction

II

8Accessories 42

8.1.1Sorting System CHRONOS®120 42

8.1.2Sorting System CHRONOS®220 45

8.1.3Sorting system CHRONOS®420 48

9Maintenance / Repair 52

9.1Scope of Maintenance 52

9.2Declaration of Decontamination 54

9.3Spare Parts 55

10Faults 56

10.1General 57

10.2Possible Faults CHRONOS®58

11Warranty 60

Introduction

1

BIOSAFE ®120/220/420 MDß is a medical device of Class II a

according to Directive 93/42/EWG of the Council of 14 June

1993 for medical devices.

With the medical device BIOSAFE®120/220/420 MDß for

example the following cell and tissue samples are long-term

stored by using liquid nitrogen (LIN) as cryogenic agent at

temperatures below -130° C for the return into the human

being:

•sperm, ovum

•ancestral cells, bone marrow

•blood components, e. g. erythrocytes

•heart valves

•skin, bones, teeth

as well as e. g.

•samples for the DNA – analysis in gene technology

The preconditions for this are

•that the samples are tightly packed in packaging suitable for

liquid nitrogen temperatures.

•that the samples were deep-freezed correctly.

•That the medical device BIOSAFE®120/220/420 MDß is

operated properly according to the regulations.

Informs of dangerous situations resulting in possi-

ble

•Personal injuries

•Environmental damage

•Machinery damage

Voltage hazard

Indicates

•Advices

•Exemplifications

•Supplements

Warning of Squeezing Danger

1 Introduction

1.1 Symbols in the Manual

Introduction

2

The medical device BIOSAFE®120/220/420 MDß may only

be operated according to this operating manual.

Before commissioning, it is absolutely necessary to read

the operating manual completely.

The BIOSAFE®120/220/420 MDß may only be operated by

trained and instructed personnel.

Immediately after receipt of the unit, check delivery with

regard to

•completeness

•damage

In case of transport damage, inform

•transport insurance

•transport company

•supplier

1.2 Principle

1.3 Delivery

Component Overview

3

The medical device BIOSAFE®120/220/420 MDßconsists of

two components:

•Level control unit and vessel control system BIOSAFE –

CONTROL®ß, with level probe, temperature probe, evalua-

tion software for PC and holding device at CHRONOS®

120/220/420

•Cryogenic Storage Vessel CHRONOS®120/220/420 with

designer cover with vacuum insulated panel, solenoid

valve, cover switch and safety intermediate piece under a

cover, insulated decanting hose

Optional component:

•„I / O Box“ for connecting external alarms, main shut-off

valve, analogue output for temperature documentation

Accessories:

Sale by:

Cryotherm GmbH & Co. KG

•aluminum sorting system

No medical device

2 Component Overview

Cryogenic Storage Vessels CHRONOS®120/220/420

4

3 Cryogenic Storage Vessels

CHRONOS®120/220/420

3.1 Specifications of the Vessels

CHRONOS®120/220/420

CHRONOS®

120

CHRONOS®

220

CHRONOS®

420

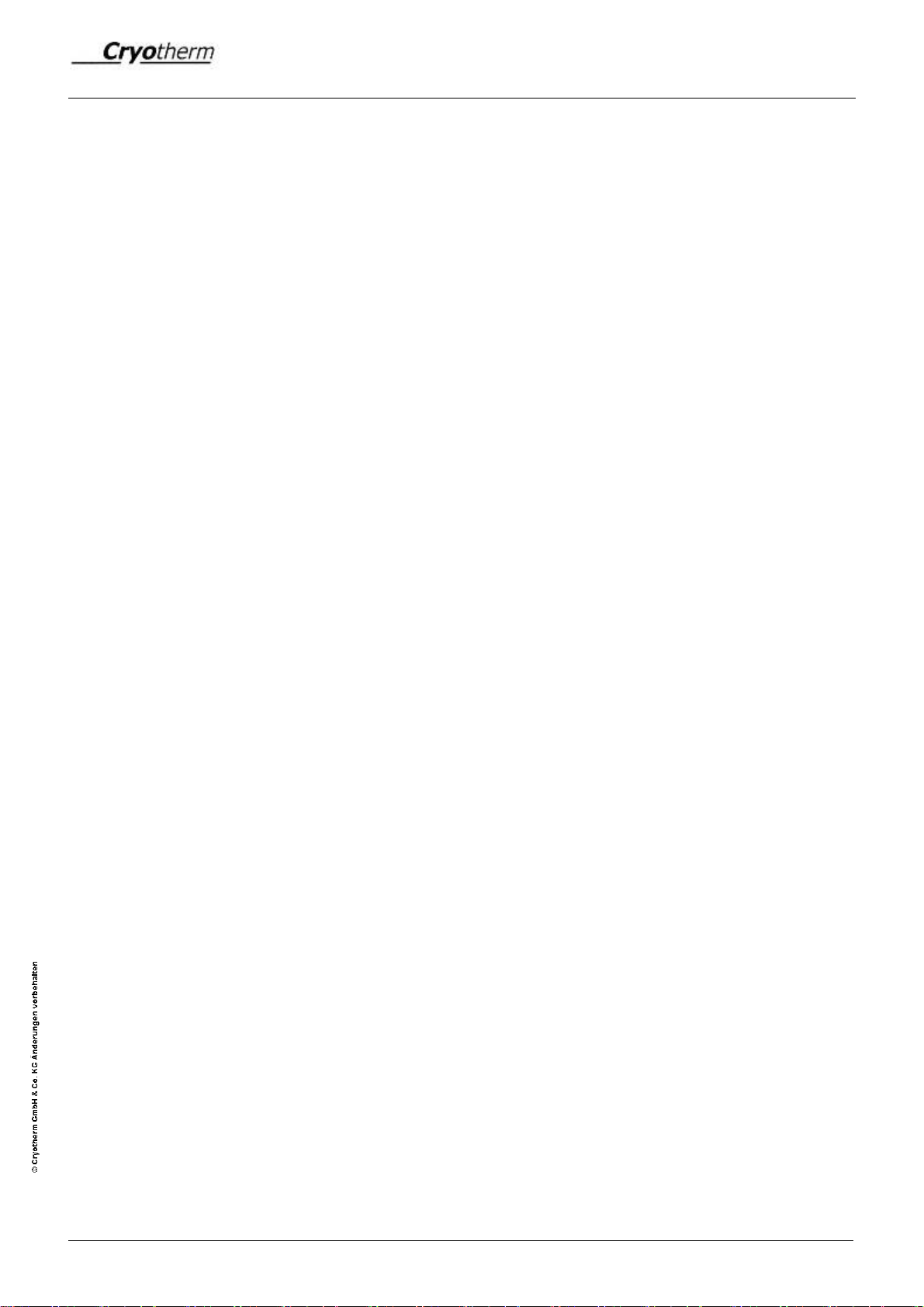

1. Width B 56 cm 72 cm 90 cm

2. Depth T 70 cm 85 cm 103 cm

3. Total height of Vessel H

(cover closed) 112 cm 120 cm

119 cm

4. Assembly width A 80 cm 80 cm 96 cm

5. Assembly depth D 80 cm 75 cm 95 cm

6. Assembly width

BIOSAFE-CONTROL®ß

80 cm 95 cm

110 cm

7. Height with

BIOSAFE-CONTROL®ß 125 cm 125 cm

125 cm

Cryogenic Storage Vessels CHRONOS®120/220/420

5

CHRONOS®220 CHRONOS®420

8. Vessel height, cover opened H1 107 cm 107 cm

9. Space required: Depth F 91 cm 116 cm

10. Space required: Width G 141 cm 175 cm

11. Space required: Distance J 42 cm 62 cm

12. Space required: Distance J1 55 cm 75 cm

13. Space required: Height H3 137 cm 137 cm

14. Space required: Height H4 168 cm 168 cm

Behälte

G

D

Wand

H

Deckel

Behälte

J

Position Deckel

J

Cryogenic Storage Vessels CHRONOS®120/220/420

6

Caution! The positive pressure relief and seal-off

device protects the vacuum room from overpres-

sure. Re-evacuation may only be carried out by

•manufacturer’s skilled staff

The protective cover (2) intercepts the valve insert

(1), when there is overpressure existing in the vacu-

um room.

•Do not remove the protective cover (2).

•Protect the valve from heat as well as cooling, as

brittleness results in the loss of the operating vacuum.

CHRONOS®

120 CHRONOS®

220 CHRONOS®

420

Total geometrical capacity 151 251 415 l

Geometrical capacity below the

storage shelf (LIN reserve) 21 35

57 l

Geometrical capacity above the

storage shelf (cubic capacity) 130 216

358 l

1decimetre filling height corre-

sponds to

21 35 57 l

Operating overpressure 0 0 0 bar

Empty weight 100 175 225 kg

Outside diameter 560 710 900 mm

Inside diameter 514 664 854 mm

Storage height 625 625 625 mm

Operating height (upper edge of

the vessel with open cover) 1045 1070

1070 mm

Total height 1150 1180 1190 mm

Roller diameter 80 80 Mm

Static rate of evaporation

(measured with gas phase stor-

age)

2,3

3,5

2,0

5,0

1,5

≈6,2

%/d

l/d

Holding time (LIN Reserve) 4,5 58 d

3.2 Structure of the Vessel

3.2.1 Combined Positive Pres-

sure Relief and Seal-off De-

vice

Cryogenic Storage Vessels CHRONOS®120/220/420

7

As an option, the cryogenic storage vessel CHRONOS® can

be equipped with a roller base. This roller base features 4

casters, 2 of which are equipped with locking levers.

Transport with roller base

It is absolutely necessary to carry out transport over

uneven grounds and stairs with 2 persons.

Transport with fork lifter

The CHRONOS®120 Vessel can be transported with a fork

lifter.

Special fork lifter pockets are not provided. Therefore, it is

absolutely necessary to secure the vessel with conventional

means during the transport with a fork lifter.

Danger of tumbling down during unsecured transport.

It is absolutely necessary to secure the vessel at the fork

lifter with suitable means (tightening straps) before

transport.

3.2.2 Castors /

Transport possibilities

CHRONOS®120

Cryogenic Storage Vessels CHRONOS®120/220/420

8

The cryogenic storage vessel CHRONOS®220 is equipped

with 2 fixed castors without locking levers in the rear area and

two adjusting feet in the front area. Thus, it is ensured that the

vessel is stable in operating condition and cannot be moved

without special devices

For the transport of Vessel CHRONOS®220/420,two

possibilities are given:

- by means of the additional transport device (article no.

78202830)

- by means of a fork lifter

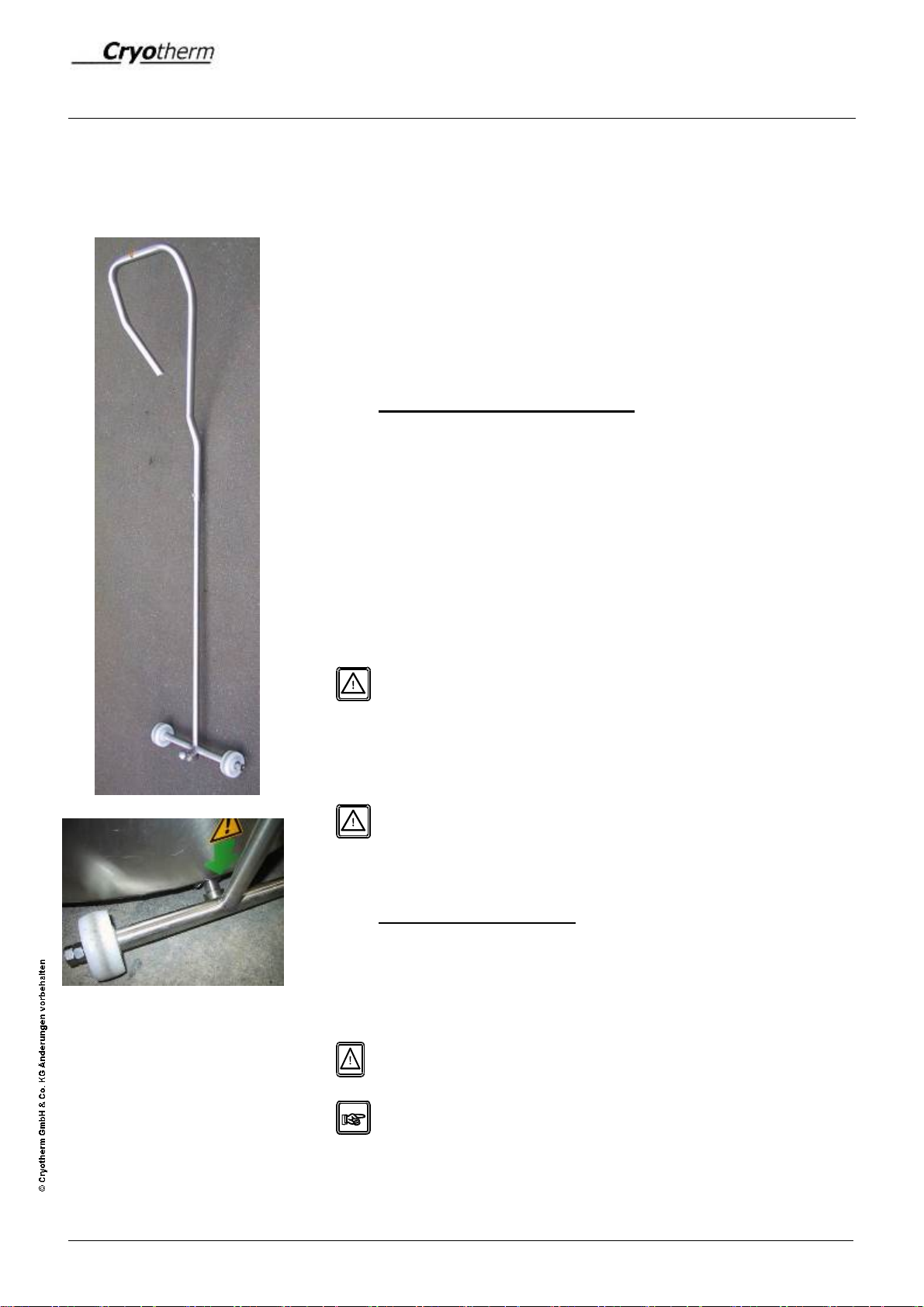

Transport with transport device

The transport device (article no. 78202830) is intended for

transporting vessels over small or middle distances (mainly

inside buildings) and for shunting inside the laboratory.

The transport device is a frame with handle, two castors and a

hemispherical journal placed in the lower area.

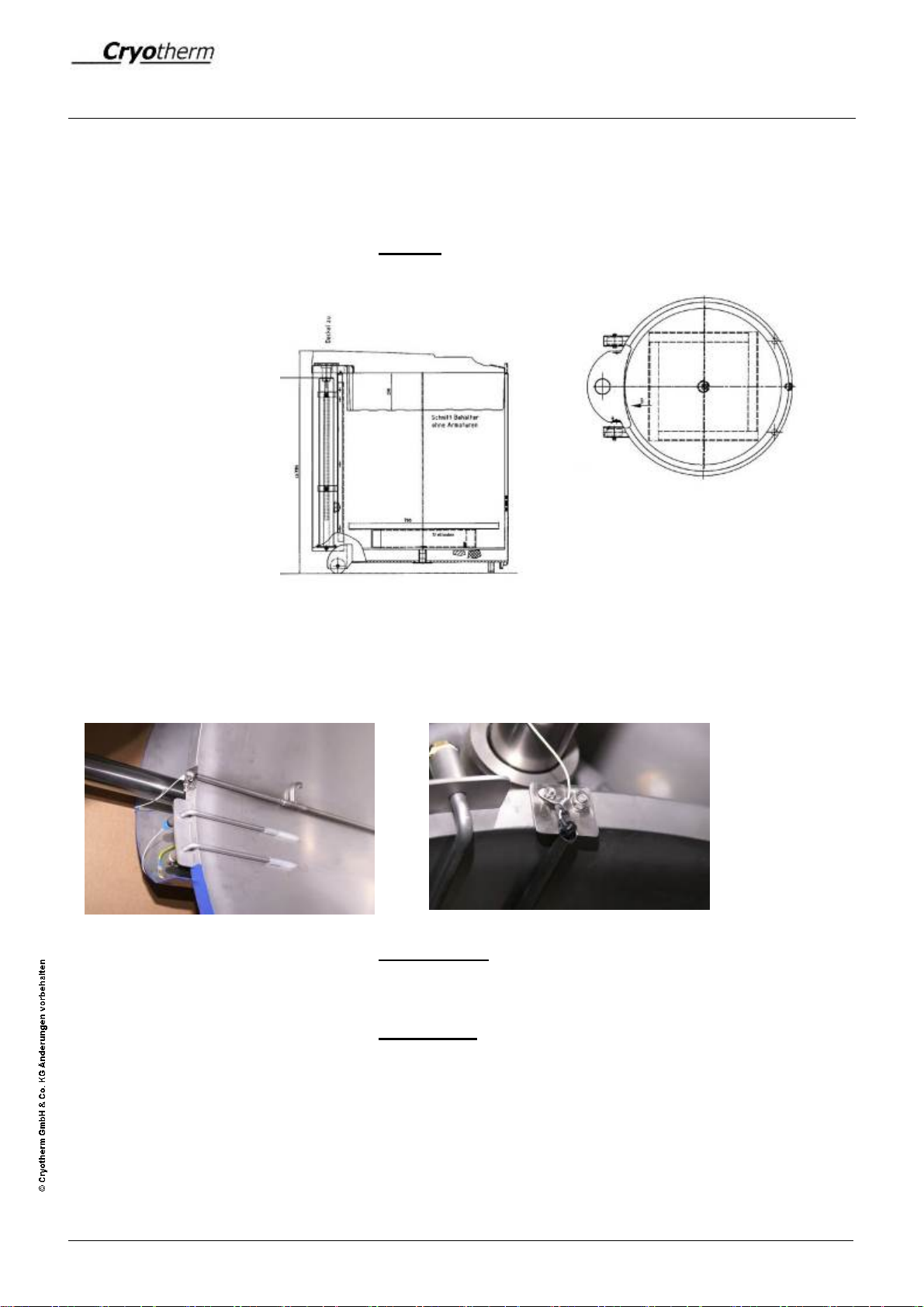

At the vessel bottom (in the front area), there exists the

corresponding accommodation for hemispherical journals of

the transport device (marked with a green arrow label).

By means of the transport device, the vessel is slightly lifted in

front, is thus placed on four castors and can be moved.

Danger: trapping of the fingers

By means of the transport device, hindrances up to a height /

depth / width of 20 mm (e. g. steps) can be overcome.

.

Danger: Due to the weight of the vessel, the handle of the

transport device can hit back. Do not let go of the

transport device during transport.

Transport with fork lifter

The CHRONOS®220/420 Vessel can be transported with a

fork lifter.

Special fork lifter pockets are not provided. Therefore, it is

absolutely necessary to secure the vessel with conventional

means during the transport with a fork lifter.

Danger of tumbling down during unsecured transport.

It is absolutely necessary to secure the vessel at the fork

lifter with suitable means (tightening straps) before

transport.

3.2.3 Castors /

Transport possibilities

CHRONOS® 220/420

Cryogenic Storage Vessels CHRONOS®120/220/420

9

Adjustable feet (CHRONOS 220/420)

The feet at CHRONOS 220/420 can be adjusted in height.

For this, loosen the upper lock nut first and then adjust the foot

with the lower nut in height or depth.

Subsequently, tighten the upper lock nut again.

CAUTION

Do not unscrew the foot completely!

The vessel is equipped with a detachable cover. The cover

reduces the penetration of humidity and minimizes the

penetration of additional heat into the vessel.

A lock is integrated in the cover. Thus, the access to the

contents of the vessel is limited.

Danger at the lock: trapping of the fingers

For handling the cover, two cover handles are provided.

The handles of the vessel are exclusively intended for

operating the cover and must not be used for any other

purposes.

Opening of the vessel cover

First of all, unlock the lock for opening the vessel. After that,

the cover has to be lifted.

Should any frost formation be apparent at the cover,

remove it with open cover!

Closing the vessel cover

For closing the vessel cover, put the cover on the vessel

again. Shut the lock after closing.

Danger at the lock: trapping of the fingers

3.2.4 Cover

CHRONOS® 120

Cryogenic Storage Vessels CHRONOS®120/220/420

10

The vessel is equipped with a liftable - slewable cover. The

cover reduces the penetration of humidity and minimizes the

penetration of additional heat into the vessel.

A lock is integrated in the cover. Thus, the access to the

contents of the vessel is limited

Danger at the lock: trapping of the fingers

For handling the cover, two cover handles are provided.

The handles of the vessel are exclusively intended for

operating the cover and must not be used for any other

purposes.

Cover opening mechanism

The cover opening mechanism serves for facilitating the

opening and closing of the cover. The cover opening

mechanism consists of a lifting mechanism with integrated gas

pressure spring.

The pressure inside the gas pressure spring is adjusted in

such a way that the cover cannot leave the vessel completely

itself. This pressure ensures the perfect function of the cover

opening mechanism

The pressure inside the gas pressure spring has to be

examined during the annual maintenance and readjusted,

if necessary.

Opening of the vessel cover

First of all, unlock the lock for opening the vessel. After that,

the cover has to be lifted upwards to the limit stop and

subsequently swivelled aside. In tilt-out condition the cover is

blocked and protected against falling down.

After opening, block the cover by tilting-out aside.

Possible frost formation at the cover edge can possibly

result in the fact that the cover does not move upwards

itself after opening the lock handle.

For opening, loosen the cover at the handles with lateral

movements and moderate pulling upwards.

Should any frost formation be apparent at the cover,

remove it with open cover!

3.2.5 Cover / Elevating Mecha-

nism

CHRONOS® 220/420

Cryogenic Storage Vessels CHRONOS®120/220/420

11

Closing the vessel cover

For closing the vessel cover, swing back the cover first, so that

the cover is located above the vessel. At the same time, the

blocking is loosened. After that, carefully lower the cover. Shut

the lock after closing.

Danger at the lock: trapping of the fingers

EMERGENCY - PROCEDURE

In case that the lifting mechanism is obviously blocked with

closed or opened cover, carry out the following emergency -

procedure after consulting the CRYOTHERM – SERVICE

(Hotline: 02741 – 95 85 75):

Opening: Loosen 4 fastening screws between cover and

lifting mechanism. The cover can then be lifted

with 2 persons.

Closing: Loosen the cover as described and insert into the

vessel as much as possible in slightly turned po-

sition.

Cryogenic Storage Vessels CHRONOS®120/220/420

12

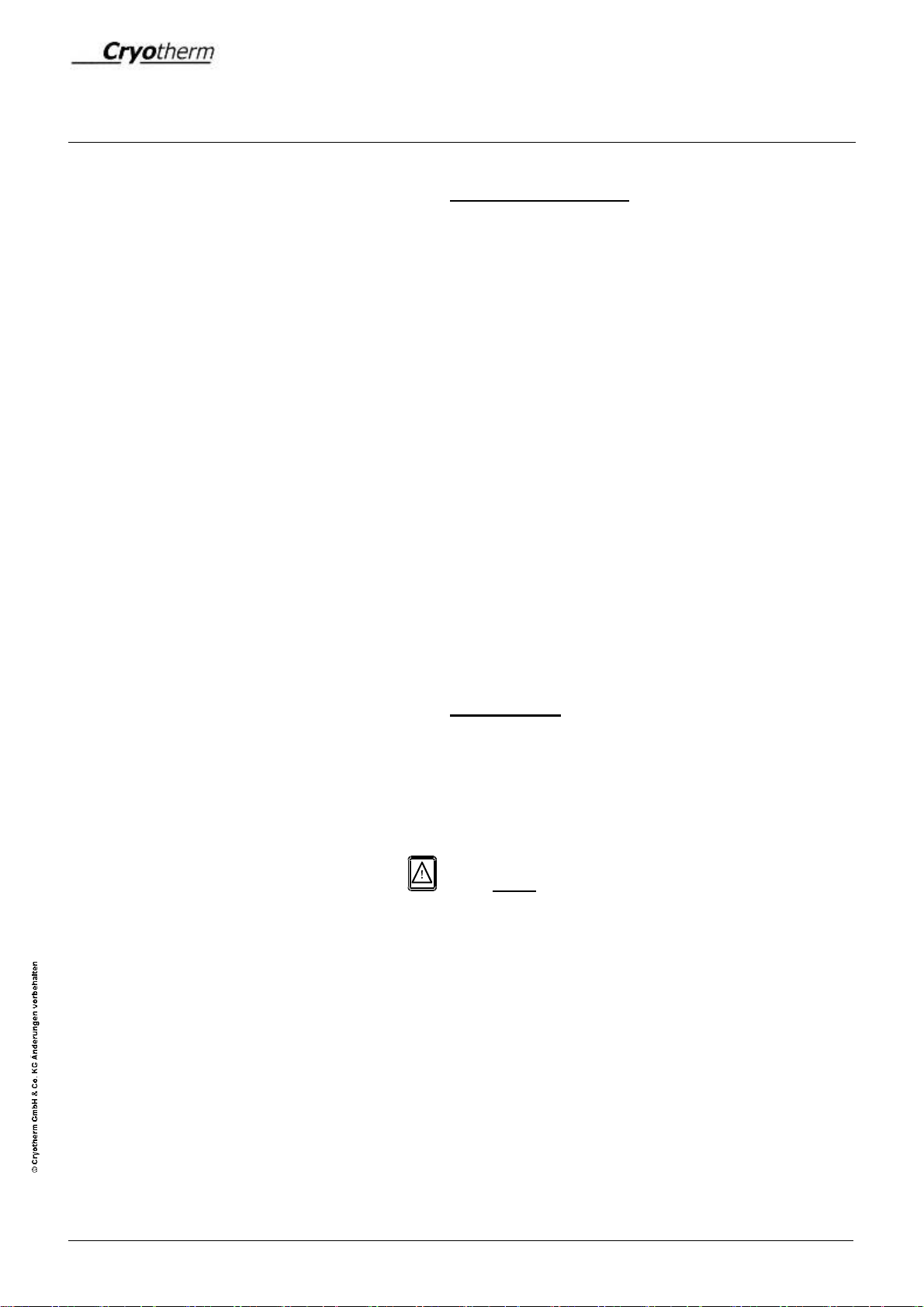

The storage shelf is a storage level loosely inserted into the

vessel and is located on a storage frame made of aluminum.

Picture:

CHRONOS® 220/420

Right picture:

The level probe of BIOSAFE-CONTROL® ß is inserted into the

splash guard pipe (center) provided for this.

Left picture:

Between the LIN fill line (left) and the splash guards pipe

(right) for the level probe, there exists the instrument leads for

the temperature probe of the BIOSAFE-CONTROL®ß

3.2.6 Storage Shelf / Storage

Frame

3.2.7 Connection for Level Control

Unit and Vessel Control Sys-

tem

BIOSAFE – CONTROL® ß

Cryogenic Storage Vessels CHRONOS®120/220/420

13

The fill connection is a detachable 3/8” screwed pipe.

At this connection, the decanting of the LIN supply is

connected.

The fill pipe ends inside the vessel below the cover insulation

and is slightly bevelled.

It prevents the splashing of the level probe or of the sorting

system.

3.2.8 Fill Connection

Level Control Unit and Vessel

Control System

BIOSAFE-CONTROL® ß

14

Languages

•The device display readings and the PC software can

be set to German or English. Combinations are pos-

sible, too, i. e. German display and English PC soft-

ware or German PC software and English display.

Level control

•The level of the liquid nitrogen inside the storage ves-

sel is kept between minimum and maximum.

•If the level falls below minimum, a solenoid valve is

triggered and liquid nitrogen continues flowing into the

storage vessel.

•A delayed reaction between 0 and 999 minutes can

be selected for the magnetic valve (1). This delay

cannot be set for “Filling after Min. Alarm” and “Manu-

al Filling”.

•The filling procedure is stopped as soon as the level

reaches the maximum level.

•If the level falls below the minimum alarm level or

exceeds the maximum alarm level, a visual and

acoustic alarm is triggered. In addition, an alarm out-

put is connected..

•The level and the operating states are displayed both

at the device and at the PC.

•Delay times for triggering an alarm can be set both at

the device and via PC.

•All alarms can only be activated or deactivated via a

service menu in the PC software (1). This menu can

only be accessed by service personnel. At the time of

delivery ex works all alarms are activated.

•With opened cover, automatic refilling is suppressed.

Manual refilling (e. g. for unfogging) is possible.

•The distances between the sensors of the level probe

(standard design) are as follows:

Minimum alarm to minimum: 3 cm

Minimum to maximum: 4 cm

Maximum to maximum alarm: 3 cm

•Alternatively there is a level control probe spaced at

2 cm/2cm/2cm. If required, please contact the

manufacturer or service.

•In order to set the requested level in the storage ves-

sel, the vessel probe has to be inserted more or less

deeply into the instrument leads provided for this.

4 Level Control Unit and Vessel

Control System

BIOSAFE-CONTROL®ß

4.1 Functions

Level Control Unit and Vessel

Control System

BIOSAFE-CONTROL® ß

15

Temperature - Control

•The temperature inside the storage vessel is con-

trolled, displayed (at the device and the PC) and

logged.

•If an adjustable limiting value for the storage

temperature is exceeded longer than the period of

time selected for this, an alarm is recorded, dis-

played and triggered.

•The values for the storage temperature are stored

every 15 minutes.

•If the temperature is above the limit, the log rate for

the temperature values is increased from 1 reading

every 15 minutes to 1 reading per minute. Thus the

progression up to exceeding the limiting temperature

is displayed with a higher resolution and is thus more

accurately traceable.

•A graphic evaluation of the temperature course can

be carried out via PC.

•Delay times for triggering an alarm and the maximum

allowable storage temperature can be set both at the

device and via PC

•Display range: -200 °C to +50 °C

Cover control

•The opening condition of vessel cover is determined

by means of a cover switch.

•The opening of the cover is registered and indicated.

•If an adjustable period of time is exceeded for cover

opening, an alarm is triggered.

Note:

Vessels without a cover switch must be bridged.

Level Control Unit and Vessel

Control System

BIOSAFE-CONTROL® ß

16

Display/Indication

•The display language can be set to German or Eng-

lish.

•On the display are indicated;:

- storage temperature

- level (between minimum and maximum)

- messages (operating state, information, alarm

messages)

•In addition, the

- vessel no. (= ID) (1 to 32)

- date and time (prevailing)

- date and time of an occurred alarm message

and

•information on:

- data connection to the Master („M“)

- automatic refilling is triggered („F“)

- device is switched „inactive“ ( „ i “ )

are indicated.

•With alarm messages, the background lighting of the

display flashes.

Acoustic and visual alarm

•With alarm messages, the background lighting of the

display flashes.

•On the display, the prevailing alarm is indicated in

plain text.

•In addition to the visual alarm message, an acoustic

warning takes place.

This manual suits for next models

2

Table of contents