CS Medical Systems TD-100 User manual

TD-100™

Transesophageal (TEE) Ultrasound Probe

Disinfector

SER ICE MANUAL

Manufactured by:

3300 Lake Woodard Dr.

Raleigh, NC 2 604 USA

www.csmedicalllc.com

Sales: sales@csmedicalllc.com

Customer service: service@csmedicalllc.com

Phone: (8 ) 255-94 2

Phone: (919) 255-94 2

Fax: (919) 212-8050

200664 Rev A

UNCONTROLLED

TD-100™ is a registered trademark of CS Medical LLC.

TD-100™ Probe Disinfector Operators Manual

Table of Contents

Section Pages

1 TD-100™ System

1.1 Signal Words/Definitions 4

1.2 Illustration of the TD-100™ Probe Disinfector 6

1.3 System Overview of TD-100™ Probe Disinfector

1.4 Site Specifications 9

-Electrical Requirements

-Water Requirements

-Environmental Requirements

-Classification

2 TD-5™ High Level Disinfectant

2.1 Vapor Control 11

2.2 Emergency Shut Down Procedures 12

3 Operating Instructions

3.1 Aborted Cycle 13

4 Quality Assurance

4.1 Valid Cycle Printout 14

4.2 Aborted/Invalid Cycle Printout 15

4.3 Troubleshooting 16

4.4 Water Supply Problem

4.5 Diagnostic Failure 1

4.6 Trouble Shooting 18

2 200664 Rev A

UNCONTROLLED

Section Pages

5 Maintenance

5.1 Daily Checks and Daily Cleaning 21

5.2 Changing the Printer Paper 22

5.3 Changing the Air Filter 23

5.4 Setting or Changing the Time and Date 24

6 Warning and Caution Statements

6.1 Warning Statements 25

7 Spare Parts

.1 Spare Parts List 26

8 Contact Information

8.1 Contact Information 2

3 200664 Rev A

UNCONTROLLED

SECTION 1: TD-100TM System

Section 1.1: Signal Words/Definitions

WARNING! - INDICATES A POTENTIALLY

HAZARDOUS SITUATION, WHICH IF NOT

A OIDED, COULD RESULT IN DEATH OR

SERIOUS INJURY.

CAUTION! - INDICATES A POTENTIALLY

HAZARDOUS SITUATION, WHICH IF NOT

A OIDED, MAY RESULT IN MINOR OR

MODERATE INJURY. IT MAY ALSO BE

USED TO ALERT AGAINST UNSAFE

PRACTICES OR POTENTIAL EQUIPMENT

DAMAGE.

Definitions

Purge: Purge is when the unit is drained prior to starting a run, during normal

operation or when a run is interrupted.

TD-5™: TD-5™ is the bottle which contains the disinfectant.

Symbols

~Symbol for Alternating Current

4 200664 Rev A

UNCONTROLLED

WARNING!

THE TD-100™ IS DESIGNED FOR USE WITH TEE ULTRASOUND

PROBES ONLY.

THESE INSTRUCTIONS MUST BE PLACED IN A ISIBLE

LOCATION.

DO NOT USE THIS SYSTEM UNTIL IT HAS BEEN PROPERLY

INSTALLED.

THE TD-100™ SYSTEM MAY NOT BE USED IN EXPLOSION

ENDANGERED AREAS.

CONNECT THE SYSTEM TO A HOSPITAL GRADE, GFI

RECEPTACLE ONLY. GFI OUTLET MUST BE TESTED ON

A REGULAR BASIS PER THE GFI MANUFACTURERS’

RECOMMENDATION.

DO NOT ATTEMPT TO ACCESS NON-USER SER ICEABLE

COMPONENTS OF THE TD-100™ SYSTEM.

DO NOT OPERATE THIS UNIT IF THE POWER CORD

APPEARS DAMAGED OR FRAYED IN ANY WAY.

CAUTION!

ONLY ULTRASOUND PROBES LISTED IN THIS MANUAL

MAY BE USED WITH THIS SYSTEM - SEE LIST IN

SECTION 9.2.

DO NOT OPERATE THIS UNIT IF DISPLAY IS BLANK OR

HARD TO READ. IF DISPLAY IS HARD TO READ, CALL

CUSTOMER SER ICE.

5 200664 Rev A

UNCONTROLLED

Illustration of the TD-100™ Probe Disinfector

Fig. 1 Typical installation of the TD-100TM.

6 200664 Rev A

Fig.1 TD-100™

Probe Door

TD-5 Door

Electrical

Connection

Holder

Air Filter Door

UNCONTROLLED

1.3 System Overview of TD-100™ Probe Disinfector

The TD-100™ is an automated disinfector that is designed to provide high-level

disinfection of transesophageal (TEE) ultrasound probes. A TEE ultrasound

probe is considered a semi-critical device that enters the body through the

esophagus. The TD-100™ rinses the disinfected TEE probe using high quality

potable water.

Note:

When using potable water for rinsing, the user should be aware of the

increased risk of recontaminating the TEE probe with Pseudomonas and

atypical (fast growing) Mycobacteria often present in potable water supplies.

Additionally, Mycobacteria are highly resistant to drying; therefore, rapid

drying will avoid possible colonization but may not result in a device free

from atypical Mycobacteria.

Water treatment systems, such as water softeners or deionizers, may add

microorganisms to the treated water to the extent that microbial content of the

water at the point of use could exceed that of the pretreated drinking water.

To ensure proper water quality, adherence to maintenance of the water

treatment system is recommended.

The use of a bacterial retentive (0.2 micron) filter system may eliminate or

greatly reduce the amount of waterborne bacteria from the potable water

source. Contact the manufacturer of the filter system for instructions on

preventive maintenance to avoid colonization or formation of biofilms in the

filter.

Endoscopes with their intricate channels can provide ideal situations for rapid

colonization of bacteria. Although TEE probes do not have any internal

channels, there is still the potential for colonization of waterborne bacteria.

Waterborne bacteria are highly resistant to drying; rapid drying will avoid

possible colonization. A final drying step is recommended following the TEE

probe manufacturer’s recommendations. In the absence of a recommended

drying procedure the following is recommended: A final wipe down using

0% isopropyl alcohol solution is useful to speed the drying process and

reduce the numbers of any organism present as a result of rinsing with potable

water.

Although these bacteria are not normally pathogenic in patients with health

immune systems, AIDS patients or other immuno-compromised individuals

may be placed at high risk of infection by these opportunistic

microorganisms.

The system uses TD-5™ disinfectant, which is designed only for use with the

TD-100™. The disinfectant is packaged in 500ml bottles. One bottle of

disinfectant is used for each process cycle. The disinfectant bottles are not

designed to be re-used in the system. It is a violation of Federal law to use this

product in a manner inconsistent with its labeling.

200664 Rev A

UNCONTROLLED

During each disinfection cycle, the machine itself is disinfected with the TD-

5™ disinfectant. All wetted surfaces and components within the TD-100™ are

exposed to the same disinfection conditions as TEE probes. After being

disinfected these same surfaces, components and TEE probes are rinsed free of

any residual TD-5™ disinfect, completing the disinfection cycle.

The TD-100™ is microprocessor controlled and will automatically disinfect the

probe once the cycle begins.

WARNING! TEE PROBES MUST BE PRE-CLEANED PRIOR

TO USE IN THE SYSTEM. SEE PRE-CLEAN

INSTRUCTIONS IN SECTION 3 OF THIS

MANUAL.

The TD-100™ will take approximately 1 minutes to complete the disinfection

and rinse cycles, after which the TEE probe is removed from the machine.

At the end of a cycle, a printout will allow the user to verify that the machine

has completed a valid cycle. If an error occurs during the process the run is

invalidated and an error report prints.

At the end of a valid cycle, the TEE probe must be removed from the system

and dried according to the probe manufacturer’s recommendations.

The unit is placed on the floor against a wall. The installation kit includes four

wall brackets for support. It requires an electrical connection to a 120V outlet,

water and drain connections.

8 200664 Rev A

UNCONTROLLED

9 200664 Rev A

UNCONTROLLED

1.4 Site Requirements and Specifications

Actual Size

Width 24” [61cm]

Depth 8” [20.32cm]

Height 44” [112cm]

Weight 0 lbs [32kg]

Electrical Requirements

Service 120 V~ (VAC), 20 Amp, 60 HZ-

dedicated circuit terminated in 20 Amp

hospital grade GFCI double wall

receptacle

Ratings 120 V~, 60 Hz, 8A

Fusing Fast Acting, 10A, 125V, 5mm X 20

mm Cooper Bussman GMA-10A (or

equivalent)

Water Supply Requirements

Delivery pressure Regulated to 20-25 PSI

Using a Watts 263A with a pressure

gauge and female ¼” NPT outlet (or

equivalent)

Flow rate 1gpm at 20 PSI Minimum

Temperature Cold water supply: 50 - 80 degrees F

Shut-off A shut-off valve is recommended

Connection 10 feet of ¼” ID Tubing (provided in

installation kit)

10 200664 Rev A

UNCONTROLLED

Quality High quality potable water; a high

quality potable water is one that meets

Federal Clean Water Standards at the

point of use.

Water usage Approx one gallon per processing

cycle

Drain Requirements

Drain 1½” Drain pipe no more than 18”

above the floor. A special drain

connection fitting is provided in the

installation kit.

Environmental Requirements

Indoor use

Altitude up to 2000m (6562 ft)

Maximum relative humidity 80% for temperatures up to 31ºC, decreasing

linearly to 50% at 40ºC.

Mains supply fluctuations up to ±10% of the nominal voltage

Category II installation

Pollution degree 2 environment

Room Temperature 60 – 90°F

Room Humidity 20 - 80% RH non-condensing

Classification

Protective against electric shock: Protective Class 1, ordinary protection.

11 200664 Rev A

UNCONTROLLED

SECTION 2: TD-5TM High Level Disinfectant

2.1 apor Control

The American Congress of Industrial Hygienists (ACGIH) recommends a

glutaraldehyde ceiling exposure limit of 0.05 ppm.

The TD-100™ is fitted with an air filtration system that minimizes exposure to

glutaraldehyde fumes and vapors. During factory testing, normal exposure levels

were found to be below the 0.05 ppm exposure limit. Correct use of this

equipment per the guidelines and instructions in this Operators Manual will ensure

that your exposure to glutaraldehyde vapors is minimized.

CAUTION!SHOULD YOU SMELL GLUTARALDEHYDE APORS

DURING NORMAL OPERATION, IMMEDIATELY

CHECK EXHAUST FAN OPERATION BY PLACING

HAND O ER OUTLET ON LEFT SIDE OF

MACHINE AND FEEL FOR AIR FLOW. THEN SHUT

DOWN THE SYSTEM AND FOLLOW THE

EMERGENCY PURGE PROCEDURE.

EMERGENCY PURGE PROCEDURE

1) Turn off main power switch for 10 seconds and turn back on.

2) System will purge any liquid in reservoir.

3) Once reservoir is purged, open the probe door and slowly pour in 16 oz of

clean water.

4) Allow system to purge water and repeat step 3 with another 16oz of clean

water.

5) Allow system to purge and shut off main power switch.

6) Remove TD-5 bottle, replace cap and dispose of.

) Remove probe and dry according to probe manufactures’ recommendation.

WARNING! PROBE IS NOT DISINFECTED AND SHOULD NOT

BE USED UNTIL PROPERLY DISINFECTED.

12 200664 Rev A

UNCONTROLLED

2.2 Emergency Shut Down Procedure

1) Turn the main power switch to the off position.

2) Turn off water.

AIR FILTER OR FAN FAILURE

If you smell glutaraldehyde vapors and are following correct operating procedures

per this manual; then either the fan is not working or the air filter has reached

saturation.

1) Fan failure: Check airflow with power on by placing hand over outlet on left

side of machine. If no air, call customer service.

2) Filter saturation: Change Filter (refer to Section 6.3)

13 200664 Rev A

UNCONTROLLED

SECTION 3: Operating Instructions

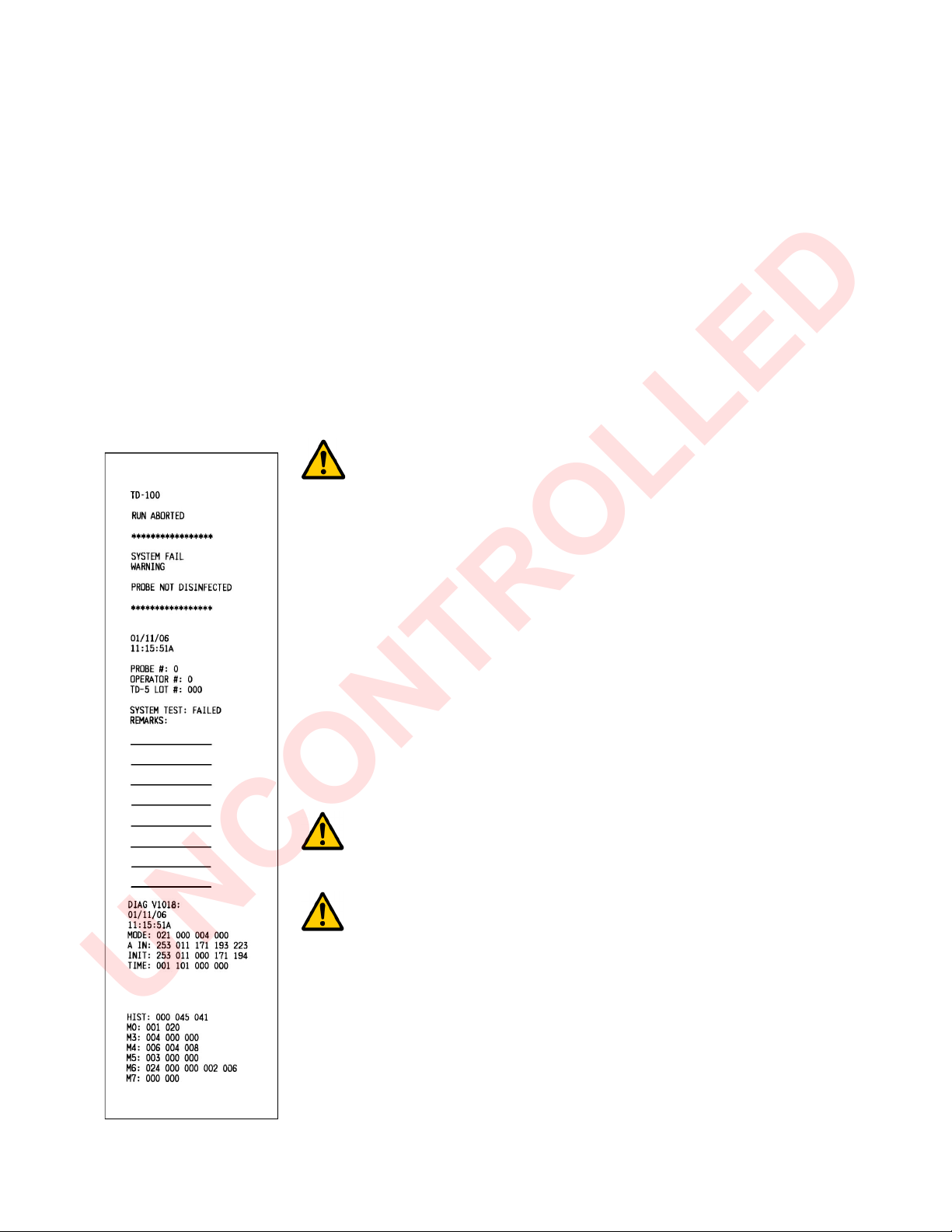

3.1 Aborted Cycle

If during the run the unit detects an error, an abort message will display. The unit will

display:

RUN ABORTED

YES REPRINT NO

The unit will print an invalid run report and request if you want a reprint of this report.

Should you run out of paper, replace paper and press “A” to reprint the aborted run. The

unit will always print “WARNING PROBE NOT DISINFECTED” whenever an

invalid run occurs for any reason.

WARNING! THE TEE PROBE IS NOT

DISINFECTED WHENE ER AN

IN ALID RUN OCCURS. THE

PROBE IS CONSIDERED

CONTAMINATED UNTIL A ALID

RUN WITH A ALID RUN

PRINTOUT OCCURS.

The printout on the left indicates an invalid run has occurred.

The system prints the date and time of the invalid run and

always lists the Diagnostics for this run and the history of

previous runs. The diagnostic information is used to assist in

troubleshooting the problem. When you call for assistance,

please have a copy of your invalid run printout.

CAUTION! ALWAYS SA E THIS PRINTOUT

FOR LATER REFERENCE.

CAUTION! ALWAYS RESET THE TD-100™

AFTER AN ABORTED CYCLE.

To reset the machine, turn the power off and then turn the

power on. This ensures that the TD-100™ purges any liquid

left in the system after an aborted run. If after resetting the

machine it is not possible to obtain a valid cycle, purge the

machine using the EMERGENCY PURGE PROCEDURE

(Section 2.4) and call customer service.

14 200664 Rev A

UNCONTROLLED

SECTION 4: Quality Assurance

4.1 alid Cycle Printout

This picture shows a valid cycle printout.

15 200664 Rev A

System ID - TD-100

Run status - Run complete (this indicates a successful

run)

Date of run

Time of run completion

Probe identification number

Operator identification number

TD-5 Lot #

Diagnostic status - System Test: Passed

Remarks:

In the remarks field you may add your own handwritten

remarks for your records. For example, you may want

to add a patient number or some other identification

number.

UNCONTROLLED

4.2 Aborted/Invalid Cycle Printout

Should the system determine an error or incorrect procedure, such as an attempt to

remove the probe during disinfection the system will abort the cycle. The system will

print an aborted run report (as shown below) indicating a failed run.

The report at the left shows that an invalid run has

occurred, “RUN ABORTED” indicates a failed run.

The TEE probe is not disinfected.

WARNING! THE TEE PROBE IS NOT

DISINFECTED WHENE ER AN

IN ALID RUN OCCURS. THE

PROBE IS CONSIDERED

CONTAMINATED UNTIL A ALID

RUN WITH A ALID RUN

PRINTOUT OCCURS.

16 200664 Rev A

UNCONTROLLED

4.3 Troubleshooting

For assistance with troubleshooting, please contact:

CS Medical

3300 Lake Woodard Dr.

Raleigh, NC 2 604 USA

Phone: (8 ) 255-94 2

Phone: (919) 255-94 2

Fax: (919) 212-8050

Email: service@csmedicalllc.com

When you call for assistance, please have a copy of your invalid run printout.

WARNING! REPAIRS BY UNAUTHOURIZED PERSONEL SHOULD

NOT BE ATTEMPTED AND WILL OID THE

MANUFACTURERS WARRANTY. UNAUTHORIZED

REPAIRS MAY ALSO DAMAGE OR MAKE UNSAFE THE

PRODUCT AND / OR ITS COMPONENTS.

4.4 Water Supply Problem

If water pressure to TD-100™ drops below 10 PSI, the display will read LOW WATER

ERR to indicate the water pressure is low. The unit will also audibly beep until the

problem is corrected.

Check water supply

•Is the inlet hose connected?

•Is the supply line kinked?

•Is the pressure gauge at 20-25 PSI static?

1 200664 Rev A

UNCONTROLLED

4.5 Diagnostic Failure

During operation, the TD-100™ is constantly checking the valid function of the

unit. If a fault is detected, the TD-100™ will shut down and an error report will

print.

The diagnostic information at the bottom of the error report can be used to help

diagnose the problem that occurred.

NOTE: Should an error occur, please have a copy of the error printout

available when you call customer service.

In most cases, there are very few operator corrections that can be made when a

diagnostic error has occurred. Any operator corrections that can be made are found

in the following chart.

18 200664 Rev A

UNCONTROLLED

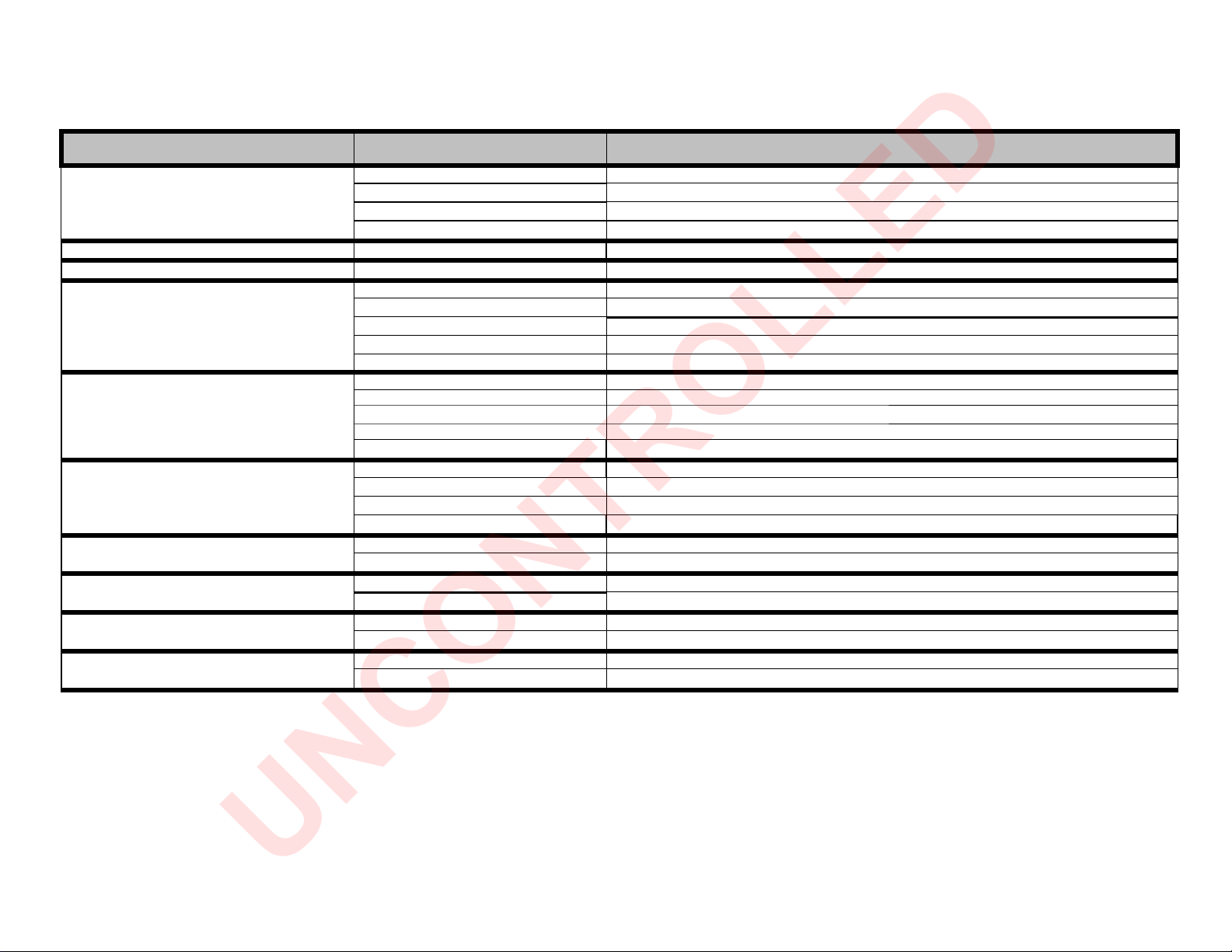

4.6 Troubleshooting

Problem/Message Possible Cause Corrective Action

Unit will not start / No display

Power switch off Verify power switch is turned on

Power cord loose or disconnected Verify that power cord supplied with unit is firmly seated in unit and wall receptacle

Tripped GFI outlet Verify that power is available at outlet

Blown fuse ontact S Medical

Display not legible Display or controller problem ontact S Medical

Unusual or chattering noise ontroller problem ontact S Medical

Low water pressure message

Water supply line not connected Verify that water line is connected per installation instructions

Water supply line obstructed Verify that water line is not pinched or kinked

Water supply valve off Verify that water supply valves are turned on

Improperly adjusted regulator Adjust to specifications

Faulty pressure sensor ontact S Medical

Pump runs continuously when turned on

Drain not connected Verify that drain line is connected per installation instructions

Drain line obstructed Verify that drain line is not pinched or kinked

Dry unit Pour one pint of water into reservoir. Water should pump immediately to drain and stop.

Faulty valve or pressure sensor ontact S Medical

Drain hose may have been shortened ontact S Medical

Liquid left in tube after run

Drain not connected Verify that drain line is connected per installation instructions

Drain line obstructed Verify that drain line is not pinched or kinked

Plugged strainer lean strainer per instructions.

Faulty pump, valve or sensor ontact S Medical

Probe does not slide easily into tube Incorrect probe Verify that probe is approved for use in the TD-100TM

Obstruction in tube lean strainer per instructions.

ycle will not progress beyond "close door" prompt Door misaligned or obstructed Visually inspect for obstructions and that door seats properly.

Faulty switch ontact S Medical

Prompt to remove probe when no probe in place Probe switch stuck Press and release switch at rear of probe holder. Verify that switch moves freely.

Faulty switch ontact S Medical

Prompt to remove TD-5™ when no TD-5™ in place TD-5™ switch stuck Press and release switch at rear of TD-5™ reservoir. Verify that switch moves freely.

Faulty switch ontact S Medical

19 200664 Rev A

UNCONTROLLED

20 200664 Rev A

Problem/Message Possible Cause Corrective Action

No printout when run completes

No printer paper Replace printer paper per instructions

Printer paper jammed Open printer door. Verify that paper runs through the slot in the printer door and is not jammed.

Printer failure ontact S Medical

Water leakage observed around unit

Leaking water supply line or connection to unit

With water supply turned off, verify that quick disconnects are properly seated and hose clamps

are tight.

Disconnected or broken drain line

Verify that drain line is properly seated into correct port. ontact S Medical for replacement it

damaged.

System overfilling during rinse ontact S Medical

Loose or missing cleanout plug Replace or tighten cleanout plug.

Internal failure ontact S Medical

Disinfectant leakage

Leaking disinfectant bottle Do not use leaking bottles. lean up per instructions.

Disconnected or broken drain line

Verify that drain line is properly seated into correct port. ontact S Medical for replacement it

damaged.

Loose or missing cleanout plug Replace or tighten cleanout plug.

Internal failure ontact S Medical

Disinfectant overflow from reservoir System not empty before starting cycle See "Liquid left in tube after run"

Disinfectant odor

Air filter expired Replace air filter per instructions

Disinfectant leakage or spillage lean up per instructions.

Doors not closed lose doors

Power interrupted during run Restart unit.

Fan failure ontact S Medical

Level error Float switch stuck Verify that float switches at rear of reservoir move freely up and down.

Faulty pressure sensor ontact S Medical

Heater error

Low disinfectant Verify that disinfectant is not leaking. If not then restart unit with full disinfectant bottle.

Plugged strainer lean strainer per instructions.

Faulty heater or thermal cutout ontact S Medical

Faulty pump or valve ontact S Medical

Heater fail Loss of heater control ontact S Medical

UNCONTROLLED

Table of contents

Other CS Medical Systems Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Dräger Medical

Dräger Medical CF 800 Technical documentation

GlideScope

GlideScope Titanium Operation & maintenance manual

Advantech

Advantech POC127 user manual

ADC

ADC Diagnostix 752M Assembly instructions

Topcon

Topcon 3D OCT-1 user manual

DeVilbiss Healthcare

DeVilbiss Healthcare IntelliPAP Standart Plus DV63 manual