ENGLISH

7. ELIMINATING FUMES DISCHARGE

Fumes discharge must comply with regulations in force and must therefore be brought above the roof. The

discharge tube must be made out of smooth steel and not the corrugated flexible type with silicone gaskets.

Furthermore it must be positioned externally and not in closed or semi-closed spaces. For example: garages,

narrow corridors, under closed roofs or any other place where fumes may collect in case of leaks. When

connecting the stove to a flue, make sure, with the services of a professional chimney sweep, that the flue is in

perfect condition. If this is not the case, it is absolutely mandatory to encase the existing flue with proper

material that will ensure correct functioning (see fig.7).

N.B.: the vertical portion of the pipes MUST be held in place with proper support so that the

weight will not damage the stove's flue header

TYPE OF TUBES USED FOR FLUES

Rigid painted steel tubes (at least 1.5 mm thick),or stainless steel ones (at least 0.5 mm thick), can be used.

The male/female coupling collars must be superimposed by at least 40mm.

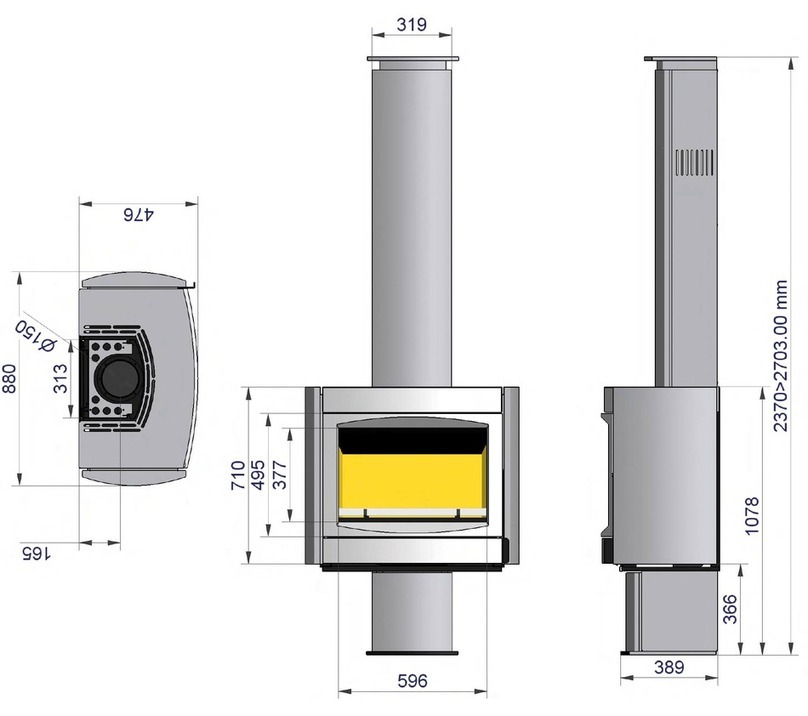

DIAMETER OF THE FLUE TUBE

The diameter of the tubes depends on the type of system. The stove has been designed for tubes with an

80mm diameter, as shown in the table, however in some cases 100mm is advisable. If 100 mm diameter tubing

is necessary, connect it to the stove using a "T" pipe connection using a ø80 - ø100 pipe fitting. (see fig. 8)

Tube length more than 5 m

For installations at an altitude of more than

1200 m a.s.l.

Note: for each 90° curve add 1 m and for each 45° add ½ m. The lengths indicated on the table are only relevant for the vertical portion.

horizontal parts must not exceed 2 m in length.

Using a "T" fitting (see fig.8) with an inspection plug, as a connection between the stove and the flue, is

mandatory. This allows both the collection of ashes deposited inside the tubes and periodical cleaning of the

flue, without having to dismantle the tubes. Since the fumes are under light pressure, ensuring that the plug for

cleaning the flue is perfectly airtight is mandatory and it must be the same after each inspection. One must

remember put it back as it was originally and check the condition of the gasket. Verify that the various tubes are

connected properly, as instructed by the manufacturer.

It is strongly advised not to place tubes horizontally, but if absolutely necessary make sure they are placed with

an angle of at least 5°.

If a traditional flue is used it is possible to connect without the need for a "T" connection tube but you must

check that the flue has a bow for collecting ash.

Connecting directly to the stove with a horizontal track that is not more than 1 m long is recommended.

If proper tube lengths are obeyed, the flue should have a draught between 10 and 12 Pa.

Do not change flue tube size in the middle of the route and especially after a bend or a horizontal portion. Verify

that there are no constrictions in the discharge conduit or in the flue.

INSULATION AND DIAMETER OF HOLES IN WALLS OR ON THE ROOF

Once the stove's position has been established and it is verified that this place is suitable for installation, one

must drill a hole for passing flue tubes. This can vary according to the type of installation, the diameter of the

flue tube and the type of wall or roof that it must pass through.

N.B.: When passing through flammable walls or roofs, use suitable mineral insulation material (mineral wool)

with a density above 80 Kg/cm.