NOTES ON SAFETY

Read these operating instructions carefully before installing the FA 510.

Failure to observe the instructions contained herein, in particular the

safety instructions, may result in hazards to personnel, equipment and

systems..

x The product may only be used in accordance with its intended purpose.

x Installation of the dew point sensor and maintenance work may only be carried

out by trained personnel.

x Installation and service work must be carried out in a de-energized state.

x The applicable safety regulations must be observed!

x All work on the compressed air network must only be carried out in a

depressurized state.

x Attention: Do not exceed the pressure range > 50 bar for the standard version.

x Observe the measuring ranges of the sensor!

Overheating will destroy the sensors.

x Observe the permissible storage and transport temperature as well as the

permissible operating temperature (e.g. protect the measuring instrument from

direct sunlight).

x Opening the instrument, improper handling or use of force will void all warranty

claims!

x Important: Before installation, briefly allow compressed air to flow off to remove

condensate and particles, this will prevent soiling of the FA 510.

x Standing air leads to long measuring times

DESCRIPTION

The FA 510 dew point sensor enables a reliable and long-term stable monitoring of the dew

point in industrial applications. The FA 510 features improved stability.

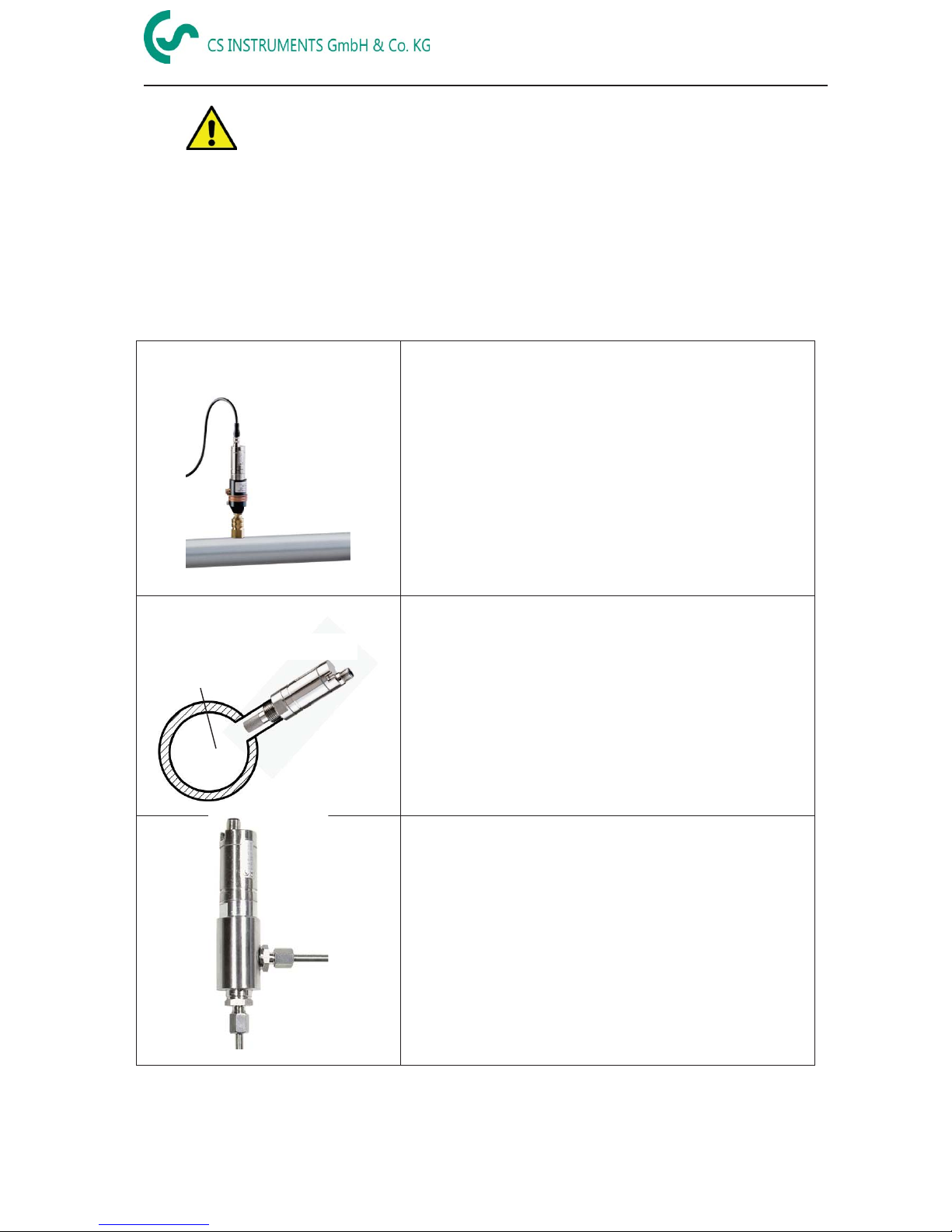

When mounting FA 510 into compressed air systems the pressure dew point (dew point

under pressure) up to 50 bar (in the special version up to 350 bar) is measured directly.

When mounting FA 510 in atmospheric conditions (ambient pressure) or in the flow off sector

(relaxed air) of compressed air systems the atmospheric dew point is measured.

Advantages:

x Dew point sensor for very low dew points down to -80 °Ctd

x Extremely long-term stable due to internal automatic calibration

x IP 65 housing grants a reliable protection in extreme industrial conditions

x Very fast response time

x Installable in the dryer by means of G 1/2" thread, optional UNF 5/8” or NPT ½”

x High accuracy of r 2 °Ctd

x Calibration on location and testing with CS control and calibration set (PC connection

set)

Programming via Software.

With the CS Service Software incl. USB / Modbus Adapter the Modbus settings, the scaling of the

Analogue output and the assignment of the measurement values could be set.

- Analogue output 4…20 mA scalable

- Switching between °Ctd,°Ftd, % RH, °C, °F, g/m³, mg/m³, g/kg, ppm, and so on

- Calibration and adjustment

- Sensor diagnosis

- Read-out of service data