CSF Inox TS Series Programming manual

INSTRUCTIONS FOR INSTALLATION, OPERATION

AND MAINTENANCE

TECHNICAL SERVICE

+39 0522 869832

TWIN SCREW PUMPS

TS RANGE

1

Contents

1 INTRODUCTION ......................................................................................................................................... 3

1.1 Symbols used..................................................................................................................................... 3

1.2 Descriptive notes............................................................................................................................... 4

1.3 Use..................................................................................................................................................... 4

1.4 Enclosed documentation................................................................................................................... 4

2 SAFETY WARNINGS.................................................................................................................................... 5

2.1 Foreseen use...................................................................................................................................... 5

2.2 Improper use ..................................................................................................................................... 5

2.3 Dangers arising from the use of the machine ................................................................................... 6

2.4 Particularly dangerous points............................................................................................................ 6

2.5 Potentially explosive atmosphere ..................................................................................................... 7

2.5.1 Marking...................................................................................................................................... 7

2.5.2 Temperature limits .................................................................................................................... 7

2.6 Maintenance warnings ...................................................................................................................... 8

2.6.1 Cleaning the machine ................................................................................................................ 8

2.6.2 Faults ......................................................................................................................................... 8

3 GUARANTEE............................................................................................................................................... 9

4 PUMP DESCRIPTION ................................................................................................................................ 10

4.1 General description of the machine................................................................................................ 10

4.2 Technical description of the machine ............................................................................................. 10

4.3 Mechanical seals .............................................................................................................................. 11

4.3.1 Single mechanical seal with external quench........................................................................... 11

4.3.2 Double flushed mechanical seal .............................................................................................. 12

5 TRANSPORTATION................................................................................................................................... 13

5.1 Transportation................................................................................................................................. 13

5.2 Receipt............................................................................................................................................. 13

5.3 Handling........................................................................................................................................... 13

6 INSTALLATION.......................................................................................................................................... 15

6.1 Pump preparation ........................................................................................................................... 15

6.2 Motor transmission couplings ......................................................................................................... 16

6.3 Changing the direction of rotation.................................................................................................. 16

6.4 Connection to the piping................................................................................................................. 17

6.5 Checks prior to start-up (!) .............................................................................................................. 18

6.6 Electrical connection ....................................................................................................................... 18

7 OPERATION.............................................................................................................................................. 20

2

7.1 Preliminary operations .................................................................................................................... 20

7.2 Operation......................................................................................................................................... 20

7.2.1 Fluid temperature.................................................................................................................... 20

7.3 CIP/SIP ............................................................................................................................................. 21

7.3.1 Flushed double mechanical seal.............................................................................................. 21

7.3.2 Single mechanical seal............................................................................................................. 21

8 DISASSEMBLY OF THE TWIN-SCREW PUMP ............................................................................................ 22

9 ASSEMBLY OF THE TWIN SCREW PUMP.................................................................................................. 31

10 ROUTINE MAINTENANCE..................................................................................................................... 39

10.1 Pump monitoring............................................................................................................................. 39

10.2 Wear parts....................................................................................................................................... 40

10.3 Spare parts....................................................................................................................................... 40

10.3.1 Bearings maintenance ............................................................................................................. 40

10.4 Repairs............................................................................................................................................. 40

10.5 Maintenance table .......................................................................................................................... 41

10.6 Lubrication....................................................................................................................................... 41

10.7 Cleaning fluids ................................................................................................................................. 42

11 WORKING IRREGULARITIES ................................................................................................................. 44

12 REMOVAL FROM SERVICE.................................................................................................................... 48

12.1 Temporary removal from service .................................................................................................... 48

12.2 Permanent removal from service.................................................................................................... 49

A. APPENDIX – TORQUE............................................................................................................................... 50

3

1INTRODUCTION

This manual contains the instructions for the C.S.F. TS pumps relative to receiving delivery, installation and

maintenance. The information given herein is of a general nature. Specific information for each version is

given in the respective annexes. C.S.F. INOX SpA reserves the right to amend or modify the content of this

manual without prior notice. This instruction manual contains the information necessary to understand and

use the twin-screw pumps produced by C.S.F. INOX SpA. We recommend reading this manual and keeping it

for future reference in a safe place near the pump itself.

When requesting information, replacement parts or assistance, always specify the pump type (*) and serial

number (**) indicated on the identification plate, or the complete part number given in the purchase

documentation.

Plate example

1.1 Symbols used

DANGER

Failure to comply with these recommendations can cause serious harm to persons

and/or objects.

DANGER

Only qualified personnel can perform operations on the electrical part.

WARNING

Identifies a danger with moderate injury risk if not avoided.

CAUTION

Identifies a danger with low injury risk if not avoided.

4

NOTICE

Identifies a risk of damage to material goods if not avoided.

1.2 Descriptive notes

Twin-screw displacement pumps are machines with two counter-rotating shafts, synchronized by a gear

placed externally to the pumping casing.

The two shafts support as many rotors, which engaging, rotate inside a gauged stator and transfer fluid

volumes separated from the suction casing to the discharge casing.

Therefore, the main elements that determine the operation of a twin-screw pump are the rotors and the

stator.

The former consist of a stainless steel screw with single or dual threads. Its sides have an optimized profile

to minimize waste flow rate during rotation.

The latter consists of a cylinder shaped according to the shape given to the rotors’ coupling.

If the rotation is reversed, so is the suction and discharge.

1.3 Use

Twin-screw displacement pumps are mainly used for viscous process fluids (up to a maximum of 1,000,000

centipoise, delicate, abrasive and with solid particles in suspension). They can also perform

Cleaning/Sterilizing in Place. They are mainly used in the food and beverage industries, pharmaceutical

industry, chemical, textile, ceramic and in water purification and treatment plants. However, this technology

has its origin in the oil sector, because the operation principle is particularly suitable for the pumping of

biphasic fluids.

The features of this type of pump are the virtually absence of pulsations and the smooth flow, for which fluid

maintains its own rheological properties.

Indeed, due to the constant quantity of conveyed fluid and to the screws’ geometry, the fluid is neither

centrifuged nor mistreated, keeping its own organoleptic properties intact as well.

Note: For the field of application of the pump in your possession, please refer to the technical sheet.

1.4 Enclosed documentation

The following documents are enclosed with this manual:

-Complete sectional drawing of the pump

-Technical parts list, with details regarding pump components and application

-EC Declaration of Conformity

5

2SAFETY WARNINGS

The following occurs during operation:

DANGER

- Electric parts are under tension.

- Mechanical parts are moving.

-

Pump casing, pipes and couplings under internal pressure. Therefore, do not

remove any protection or locking device; do not loosen screws or fastenings, as

this can cause serious damage to persons or objects.

- Absence of inspection and maintenance can cause damage to persons and objects,

especially when dangerous or toxic liquids are pumped

-

When pumping liquids at temperatures over 60°C, adequate protection and

warning signals are required.

- When you buy a pump with a bare shaft, motor coupling operations must be carried

out according to the technical standards and laws, providing adequate protections

for joints, gear belts, etc.

DANGER

- Operations on the electric parts must be carried out by skilled personnel, according

to technical standards and laws, subject to authorization from the person in charge

of installation.

- Installation must ensure adequate ventilation in order to cool the motor, as well as

enough space for maintenance operations.

Before performing operations that require the disassembling of the unit (inspection, cleaning, complete seal

replacement, etc.), the following preliminary operations must be carried out:

- switch off the motor and disconnect the electric power;

- close valves on suction and outlet pipelines in order to avoid the risk of inundation;

- use adequate protections for hands and face, if the pump contains liquids that are injurious to health (for

example acids, solvents, etc.);

- consider if the liquid flowing out of the pump when disassembling is dangerous and arrange for adequate

safety measures.

The staff performing inspection, maintenance and assembly operations must be adequately qualified.

2.1 Foreseen use

The correct use of this machine is detailed in the order confirmation. A different use or a use that disregards

the foreseen use is not considered correct. If you want to change the product, pressure, speed or

temperature, first you need to consult our company or one of our agents.

2.2 Improper use

Any other use that differs from the one stated in the paragraph 2.1 Foreseen use is considered improper. For

example:

6

-Pumping of acids or abrasive liquids, unless otherwise approved by our company;

-Pumping of gas or gaseous substances;

-Closing the outlet valve;

-Reversing the flow, unless otherwise approved by our company;

-Dry start, etc.

DANGER

The pump must always be used in an environment suitable to the level of protection

of the motor. Always check this on the motor plate before installation.

THE PUMP MAY NOT BE USED IN ENVIRONMENTS REQUIRING A HIGHER LEVEL OF

PROTECTION OR A HIGHER MOTOR SPECIFICATION OR ELECTRICAL PARTS.

In this case, use components that comply with the safety

standards for the

environment in question.

2.3 Dangers arising from the use of the machine

The TS pump is built according to the state of the art, complying with mechanical safety standards in force.

Nevertheless, its use may pose a danger to the life and limbs of the operator or third persons and damage

the machine and other goods. The machine must only be used:

-For the purpose for which it is built.

-By complying with the safety standards.

In case of malfunction that might compromise safety, stop using it and repair it.

2.4 Particularly dangerous points

DANGER

Rotors inside the pump

Danger of crushing or amputation of fingers and hands.

Mechanical seals inspection windows

Danger of dragging, crushing or amputation of fingers and hands.

7

The pump must be protected by the costumer in a way that prevents people from inserting their hands in

the indicated openings while the rotors are moving. In case of operations with the rotors stopped, ensure

the motor cannot start accidentally. The risk is greater if the tubes are disassembled and the pump is open.

2.5 Potentially explosive atmosphere

Follow the indications on explosion protection given in this section in case of operation in potentially

explosive atmospheres.

DANGER

Only the pumps marked according to the ATEX directive and identified in such

way in the list may be used in potentially explosive atmospheres.

Special conditions apply to the use of pumps according to the 2014/34/EU

(ATEX) directive.

The use in explosive atmospheres is guaranteed only if the pump is used

according to its foreseen use (see par. 2.1).

2.5.1 Marking

The marking on the pump only refers to the pump itself.

The coupling to the drive shaft needs a proper CE marking by the manufacturer.

The motor must be taken into account separately.

2.5.2 Temperature limits

Under normal operating conditions, the maximum temperatures are expected on the external surface of the

bearings housing. Nevertheless, in case of the high temperatures of the processed media, the external

surfaces of the pumping parts may achieve the highest temperature values.

8

NOTICE

Make sure that the temperature of the fluid processed by the pump does not change abruptly.

If this is inevitable, stop the pump for enough time (see par. 7.2.1)

If the pump is supplied with a bare shaft, when selecting the coupling motor it is necessary to consider the

following conditions:

-The temperature limit allowed to the flange and drive shaft must be higher than the temperature

generated by the pump;

-Contact C.S.F. for the actual temperatures of the pump.

2.6 Maintenance warnings

Perform specified adjustment, maintenance and inspection work on time. Inform operating personnel before

starting the maintenance and repair work. Protect all plant parts and operating media connected before and

after the machine such as compressed air and hydraulics and similar against unintentional start-up. In all

maintenance, inspection and repair work switch the machine free of voltage and secure the main switch

against unexpected switching back on. Fasten and secure larger assemblies on replacement carefully to lifting

gear. Check loosened screw connections for firm seating. Use only original spare parts.

After ending the maintenance work, check the safety devices for function.

2.6.1 Cleaning the machine

Handle substances and materials used correctly, especially

-when working on lubricating systems

-when cleaning with solvents.

2.6.2 Faults

In the case of operating faults switch off the machine and secure it against unauthorized or inadvertent

starting up again.

9

3GUARANTEE

All products manufactured by C.S.F. Inox are guaranteed to the purchaser, for one year from the date of

purchase, against hidden defects in materials or manufacture, providing that they are installed and used

according to instructions and recommendations of the manufacturer. Excluded from the guarantee other

than distinctive wear and tear are repairs to damage caused by improper use, abrasion, corrosion,

negligence, defect of installation, non-observance of inspection and maintenance, use of non-genuine spare

parts, cause of accident or fortuity and from any action carried out by the purchaser not according to the

normal instructions of the manufacturer.

NOTICE

Before returning to C.S.F. Inox S.p.A. any item to be substituted or repaired under guarantee, inform

about the problem the Customer Assistance Office and follow instructions of the manufacturer.

Any item must be properly packed in order to avoid damages during the transferring and a technical

report explaining the fault occurred, must accompany the returned item/s.

Any item with a presumed fault should be returned to C.S.F. Inox S.p.A. with shipment costs at purchaser's

charge, unless different agreements are given.

C.S.F. Inox S.p.A. will examine, repair and/or replace the returned piece and then send it back to the

purchaser on ex-works basis. Should the piece be found under warranty, no further costs will be debit the

purchaser. If, on the contrary, the fault is not found under warranty, all necessary reparations and

replacements will be charged at normal cost to the purchaser. Commercial parts incorporated in C.S.F.

products are guaranteed by their corresponding manufacturers.

10

4PUMP DESCRIPTION

This chapter reports the technical features of the pump, paying special attention to the types of mechanical

seal used.

4.1 General description of the machine

4.2 Technical description of the machine

Bare shaft pump

Coupling with motor drive

Pos.

Description

1

Inlet connection

2

Pump cover

3

Pump casing

4

Intermediate Casing

5

Outlet nozzle

6

Bearing housing

7

Gear casing

8

Foot

9

Drive shaft

10

Oil plug, filler

11

Vent plug

12

Oil plug, draining

13

Lifting eyebolt

14

Joint cover

15

Coupling joint

16

Motor

17

Base

11

4.3 Mechanical seals

The mechanical seal is a device designed to retain the fluid so that it does not get out of the pump. It consists

of two sliding surfaces, one rotating in relation to the other, kept in axial contact by the pressure generated

by the fluid (hydraulic force) and by the presence of components, such as springs or bellows (mechanical

force).

The mechanical seal is usually cooled by the retaining fluid. The materials used are selected according to the

properties of the fluid used, under the conditions of use at which the seal is installed and for the required

performance. The seals installed on twin-screw pumps are reversible.

NOTICE

Before using the pump with any liquids other than those specified when selecting and ordering, ensure

that seals and gaskets are suitable for the new product.

The pump may be equipped with a set of two single or dual mechanical seals:

4.3.1 Single mechanical seal with external quench

Pos.

Component

1

Rotary gasket

2

Rotary ring

3

Fixed ring

4

Frame

5

Guide ring

6

Spring

7

Internal retaining ring

12

4.3.2 Double flushed mechanical seal

Pos.

Component

1

Rotary gasket

2

Rotary ring 1

3

Fixed ring 1

4

Frame

5

Guide ring

6

Spring

7

Fixed ring 2

8

Rotary ring 2

9

Centering spacer

Here are the flushing parameters:

Maximum pressure of the flushing system: 16 bar

Minimum flow rate of the flushing system: 0.5 l/min

For applications with high sanitary requirements, we recommend using a non-pressurized system to avoid

the contamination of the product in case of pressure drops.

In any case, the pressure difference between the processing fluid and the flushing system must not be higher

than 5 bar.

13

5TRANSPORTATION

5.1 Transportation

The packaging of all pumps manufactured by C.S.F. Inox S.p.A. is defined when placing the order. Unless prior

arrangements, the goods are packed only for transit conditions and not for long-term storage; if it should be

necessary to store the pumps outside, the pumps must be appropriately covered in order to protect the

electrical parts (motor drive) from rain, dust, humidity etc.

5.2 Receipt

When receiving the goods, ensure the packaging is intact to identify possible damage to the content occurred

during transport and report immediately to the carrier. If a damage is ascertained, the following procedure

must be observed:

-Collect the goods with reservation;

-Take the necessary pictures showing the damage;

-Notify the carrier of the damage incurred by registered mail, sending at the same time the pictures taken

to show the damaged pieces.

5.3 Handling

DANGER

Carry the packed pumps as close as possible to the place of installation using

appropriate lifting devices and unpack them. Take care during this operation, as

unsteady parts might fall down.

Dispose of any packaging material (wood, paper, cellophane, etc.) according to the corresponding rules in

force in user’s country.

After unpacking the pump, use special lifting slings and move the pump-motor unit to the place of

installation; never use the eyebolts on the motor to move the pump, as the eyebolts are for moving the

motor only.

NOTICE

In versions complete with a shroud, take the shroud off before moving the pump-motor unit in order to

avoid damage.

14

15

6INSTALLATION

6.1 Pump preparation

DANGER

Position the pump over a plain surface.

DANGER

Do not start the pump without protections to avoid contact hazards!!

The entire machine must be protected from any static charge.

The connection between the drive shaft and the pump shaft must be protected from

contact hazards!

WARNING

There must be enough space around the pump to allow for maintenance operations.

Make sure that the motor is well ventilated.

Align the pump shaft with the transmission shaft.

NOTICE

The size of the foundations must be able to support the weight of the pump.

If he pump is to be used in environments at risk of explosion, it will be necessary to use a motor with adequate

protection against explosions.

16

6.2 Motor transmission couplings

Drive for independently mounted is transmitted via flexible couplings designed to absorb impact and

torsional vibration.

These couplings compensate for both angular and radial misalignment and can sustain variations in load and

rotation inversion.

The couplings are sized in compliance with DIN 740/2 standards.

A coupling is sized so that the maximum moment transmitted by the coupling in different operating

conditions is less than the maximum permissible strain for the coupling itself.

Transmission couplings with ATEX marking are available for machines for use in potentially explosive

environments.

Pumps supplied complete with motor and base are delivered already aligned during assembly. The baseplate

may be warped, however, if fixed to an uneven surface.

Perfect alignment between the pump and motor is essential for correct operation.

As a result, after installation, we recommend checking pump-motor alignment.

RADIAL MISALIGNMENT ANGULAR MISALIGNMENT

6.3 Changing the direction of rotation

NOTICE

TS pumps have been designed to transfer the fluid in the direction stated in the following image, unless

otherwise stated in the attached list by C.S.F.

17

Subject to authorization, it is possible to reverse the fluid movement changing the direction of rotation of

the motor. Such operation is allowed for short periods at reduced differential pressures.

For more information, please contact C.S.F. via the contact details in the end of this manual.

6.4 Connection to the piping

Before connection clean the piping and remove foreign bodies (e.g. welding work).

Install universal expansion or expansion joints between the pump connections and the piping. This should

prevent vibrations of the pump being transmitted to the piping and torques acting from the piping on the

pump connections.

The pressure line should point upwards, so that later residual liquid can always flow back into the pump. This

total dry running is avoided. Further, it facilitates the later suction process.

The operator has to ensure that the pump respect the pressure agreed in the order and listed in the technical

data.

The TS pumps normally run with such a low resonant frequency that no corresponding damage is caused.

However, particularly when running with converters, certain frequencies can cause interfering vibrations,

which must be avoided. It is important during initial commissioning to ascertain whether such vibrations exist

and to define them accordingly, so that the frequency converter can then be programmed to avoid these

frequencies. Similarly, interference from cavitation or rigid lines must be ruled out.

18

6.5 Checks prior to start-up (!)

If cleaning or repairs have been performed or if the first start-up is about to be carried out, ensure all the

screws are correctly and completely screwed before starting the pump.

In case of pumps for hazardous fluids, comply with the indications provided for such materials.

The costumer must ensure that the pump is installed in the right position and with all the necessary safety

devices (sensors, switches, pressure gauges, etc.)!

The pump must always be filled with the product before the start-

up and with a liquid level above the rotor during operation (see

figure).

The pump must be filled outside the flammable area.

Ensure, before start-up, that all the valves are open. The pump will

not be able to pump to a closed valve without an overpressure

valve.

If the pump leaks, suspend the ongoing operation as soon as

possible to replace the damaged gaskets.

6.6 Electrical connection

The connection to the electric system has to be carried out after the hydraulic connection, according to the

agreements of technical directions and law (EN 60204-1).

Provide a manual power supply-disconnecting device with an adequate current breaking power. Further,

install an overload and overcurrent protection (for example cutouts, automatic switches, etc.) and if

necessary provide for a proper device to avoid spontaneous restarting.

Check that voltage, network frequency and number of phases conform to the technical features shown on

the electric motor. The safety level of all components used for electric connection (cables, cable presses,

switches and protections) must conform to the environment where the unit is installed; further, it is

important to use electric cables of suitable section corresponding to the current values indicated on the

motor plate, in order to avoid the overheating of the electrical conductors. First, carry out the motor

grounding, using the clamp on the motor and an electric conductor of suitable section. The cable connection

to the terminal box can both be star or delta connection, according to the values indicated on the motor

plate and to the network voltage shown below in the following picture; the clamps must be clean and

carefully tightened; do not force the clamps.

Lower voltage Higher voltage

19

When starting the motor, current absorption raises (5-6 times the nominal value) for a very short period; if

the network cannot bear this absorption increase, we advise to use star or delta starters or other systems

(for example auto-transformer). C.S.F. Inox S.p.A. is not liable for damages to persons and/or objects in

case of non-observance of technical directions and laws.

Table of contents

Other CSF Inox Water Pump manuals

Popular Water Pump manuals by other brands

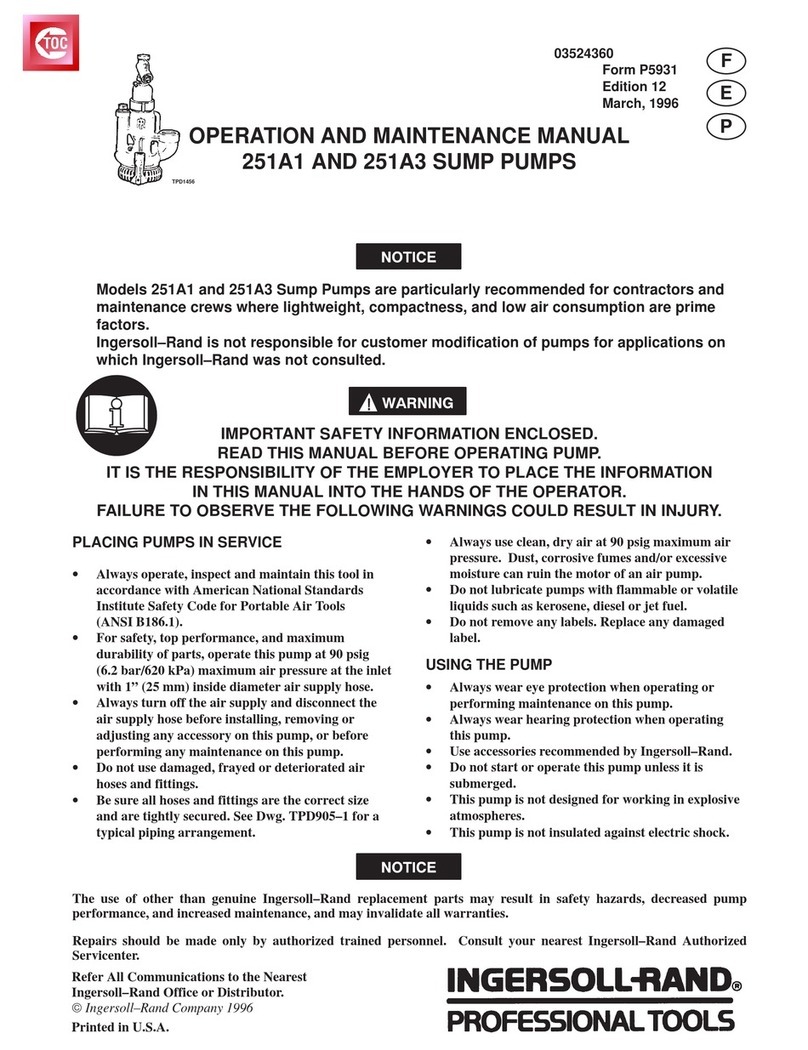

Ingersoll-Rand

Ingersoll-Rand 251A1 Operation and maintenance manual

Giant

Giant GP8135A Operating instructions/ repair and service manual

Graco

Graco Aluminum Husky 2150 LP instructions

Edwards

Edwards E1M18 instruction manual

Pentair

Pentair STA-RITE Signature 2000 manual

esotec

esotec Milano operating manual