CSM ICG 180 User manual

1

Prototype Instructions

CSM ICG 180 Piezo gyro

The ICG 180 has been designed as an easy to use beginners/sport gyro and is an

economic option to the high performance heading hold gyro.

This is a totally new design which features:

1. Durable, state of the art surface mount technology.

2. Internal vibration damping.

3. All new intelligent anti drift software.

4. Small, lightweight, single box design.

5. Built in Pilot Authority Mixing lets you stay in command through the most

strenuous manoeuvres. This eliminates the need for two gain settings.

6. Superior performance to any other gyro in it's class.

The wiring on this gyro is compatible with JR, Futaba, Hi-Tec, Graupner, Robbe and the

new style only (Blue Plug) Sanwa/Airtronics radio systems, to use this unit with other makes

of radio please check with the service centre in your country or e-mail the CSM service

centre.

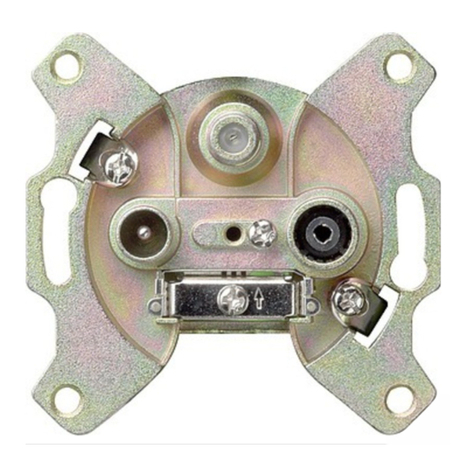

Installation

To connect, simply plug in-line between the receiver and the appropriate servo. For tail

stabilisation this will be the rudder servo.

RECEIVER

SERVO

ICG180

GYRO

CONNECTING THE GYRO

CONNECTING THE GYROCONNECTING THE GYRO

CONNECTING THE GYRO

Make sure the gyro is mounted parallel to the axis being sensed. For tail stabilisation yaw

movements are detected and the gyro should be mounted vertically (parallel to the main

rotor shaft)

2

Before final fixing you will need to identify which way up it needs to be for it to operate in the

correct sense (as described below), however at this stage identify an appropriate location

and fix temporarily until the sense check has been done.

The location should be as rigid as possible (avoid the extreme front of the model unless the

chassis is very rigid).

Avoid locations exposed to extreme heat or vibration.

To prevent vibration being transferred to the gyro make sure that the location allows at least

3mm clearance between the gyro case and any part of the model. Once the correct

operating sense has been established mount the gyro on the supplied foam tape.

Remember to mount the gyro so that the gain adjustment pot will be accessible.

Centre the rudder trim and any sub trim on the rudder channel, make sure the servo arm is

at 90°to the tail linkage. Any trim that is needed to stop the model rotating in the hover

should be done initially by adjusting the length of the tail linkage, the radio trim should only

be used after this process has been carried out and only for fine trim adjustments.

If you plan to use any form of tail compensation (pitch or throttle to rudder mixing) it is

important to make sure that the model hovers at half stick in order for this to function

properly.

The exception to this is if you use one of your radio's free mixers to create your own mixing

that does not rely on the model hovering at exactly centre stick.

It is normally best to use a larger servo arm in the range of 14 to 18mm. The arm size

depends on the individual model and the correct size can only be found by testing.

If the gyro gain can be turned up to near the maximum available then this is an indication

that the mechanical set up of the model is not correct and either a bigger servo arm or

longer tail rotor blades need to be fitted.

If only very little gain (less than about 30%) can be used before the tail starts to hunt then

this could be caused by the use of too large a servo arm but as there are many other

conditions with the model that can cause this, these should be checked first. See the trouble

shooting section for further information on this.

Checking the gyro is working in the correct sense.

As with any gyro it is vital to ensure that it operates in the correct sense. Failure to do so

may cause an uncontrollable pirouette on take off and beginners who are in any doubt about

how to set the sense correctly should seek experienced help.

First establish that the sense of the transmitter control is correct (i.e. that the application of a

right rudder command causes a change in tail pitch that will rotate the model to the right)

Once this has been done, check that turning the helicopter to the left makes the gyro apply

a tail rotor command to the right.

Axis of

invert gyro

to reverse

operating sense

ICG

180

GYRO

GAIN

GAINGAIN

GAIN

CSM

MADE IN ENGLAND

rotation

ORIENTATION AND OPERATING SENSE

If the gyro needs it's sensing reversed simply mount the unit the other way up.

3

Remember that the final fixing should be done using the foam tape supplied with

your gyro. (Spare foam is available as a CSM part)

Useful tips.

It helps to turn the gyro gain to full just while checking the sense, as this will maximise any

correction so making it easier to see.

To work out which way the tail rotor will go just remember the leading edge (front) of the tail

blades will point in the direction that the tail rotor will go, so for a left stick command you

want the tail blades to point to the right (tail swings to the right and the nose goes left)

Rotation rate.

This gyro has a degree of Pilot authority mixing built-in, so as the rudder stick is moved

away from the centre stick position the gyro automatically lowers the gain.

This means the gyro will not try to resist any deliberate rotation as strongly, so allowing a

faster rate of rotation than is achievable with other single rate gyro's.

If you find the model will not rotate as fast as desired, raise the ATV/ Travel Adjust on the

rudder channel until the desired rotation rate is achieved, it is normal for the servo to over

travel the available tail pitch slider movement by a considerable margin if high rates

of rotation are needed,in the air the gyro will reduce these movements so that it is unlikely

that the servo can be stalled while the model is in flight but avoid giving full stick rudder

commands while the model is on the ground as this could cause the servo to be stalled and

possibly damage the servo or tail linkage.

Because of this it is advisable to disconnect the servo from the linkage while setting the gyro

up on the workbench.

Setting the gyro gain.

The gyro gain is adjusted via the gain pot which is accessed through the side of the gyro

case, this is rotated clockwise to increase the gain or anti-clockwise to lower the gain.

A gain value of approximately 50% is a good starting point; this can then be adjusted as

necessary once the correct amount has been established by flight-testing.

IMPORTANT NOTE. Any change of gain will only effect the gyro once the receiver power

has been cycled (the gyro only "sees" the adjustment when the gyro is first powered up)

How much gain should you use?

Ideally you want to run the gain as high as possible, just below the point where an oscillation

(wag) will set in.

You can only find this point by flying the model and once a level of gain has been reached

where an oscillation sets in reduce the gain by just a small amount so that an oscillation will

not start.

Note.

It is normal to be able to run a higher gain in the hover than in forward flight and higher still if

a low rotor speed is used, so if the gyro has been set up for just hovering flight it will be

necessary to lower the gain a small amount to allow forward flight to be undertaken without

problems (or hovering flight on a windy day)

A useful tip to remember is if a wag is set up in forward flight then this can be stopped by

reducing the forward speed of the model.

ICG 180 Trouble shooting.

Q. No matter what I do I can't seem to adjust the gyro gain!

A. Remember any gain adjustment will only be recognised by the gyro once the receiver

power has been cycled.

Q. Every thing seems fine until just before the model leaves the ground, then the model

spins rapidly & uncontrollably.

4

A. The gyro is reversed, re-mount the gyro the other way up in the model. Note reversing

the rudder channel from the Transmitter will not correct this, the gyro must be physically re-

mounted in the model.

Q. I can't stop it wagging until I turn the gain down so low that the gyro is hardly working.

A. This can be caused by a few conditions:

The gyro should be mounted to the model in an area of minimum vibration (not at the

extreme front of the servo tray if this is flexible) & the whole model should be free of as

much vibration as possible i.e. none visible.

If the boom supports or boom support clamp are loose, this will have a large effect on the

performance of the gyro, try flexing the boom from side to side while holding the body of the

model still, watch for any movement no matter how small. The boom support clamp must not

be able to slide on the boom. Make sure all boom support ends are firmly attached and that

none of the joints can move.

Ensure that the tail linkage is as smooth & slop free as possible with no binding.

A slow or low quality servo can also cause this condition.

Q. The tail constantly twitches about and will not sit still in the hover.

A. This is caused be the gyro picking up vibration, this can be caused by an out of balance

model, a rough running engine or just by components being too loosely mounted on the

model, typically a loosely mounted canopy or battery pack/ receiver will cause resonance on

a other wise well balanced model.

Table of contents

Other CSM Accessories manuals

Popular Accessories manuals by other brands

IFM Electronic

IFM Electronic OPD100 operating instructions

System Sensor

System Sensor 2351TIR Installation and maintenance instructions

Fresh 'N Rebel

Fresh 'N Rebel 2PB6000 manual

Yamato

Yamato IN604W instruction manual

stabo

stabo Smart Control E-Plug user manual

Nokia

Nokia Flexi Multiradio BTS TECHNICAL-OPERATING DOCUMENTATION