CONTROLS

Electrical Code: All motor controls and wiring shall conform to the National

Electrical Code (Article 670 or other applicable articles) as published by

the National Fire Protection Association and as approved by the American

Standards Institute, Inc.

CONTROL STATIONS

A) Control stations should be so arranged and located that the operation of

the equipment is visible from them, and shall be clearly marked or labeled to

indicate the function controlled.

B) A conveyor which would cause injury when started shall not be started

until employees in the area are alerted by a signal or by a designated person

that the conveyor is about to start.

When a conveyor would cause injury when started and is automatically

controlled or must be controlled from a remote location, an audible device

shall be provided which can be clearly heard at all points along the conveyor

where personnel may be present. The warning device shall be actuated by

the controller device starting the conveyor and shall continue for a required

period of time before the conveyor starts. A flashing light or similar visual

warning may be used in conjunction with or in place of the audible device if

more effective in particular circumstances.

Where system function would be seriously hindered or adversely affected

by the required time delay or where the intent of the warning may be misinter-

preted (i.e., a work area with many different conveyors and allied devices),

clear, concise, and legible warning shall be provided. The warning shall

indicate that conveyors and allied equipment may be started at any time, that

danger exists, and that personnel must keep clear. The warnings shall be

provided along the conveyor at areas not guarded by position or location.

C) Remotely and automatically controlled conveyors, and conveyors where

operator stations are not manned or are beyond voice and visual contact from

drive areas, loading areas, transfer points, and other potentially hazardous

locations on the conveyor path not guarded by location, position, or guards,

shall be furnished with emergency stop buttons, pull cords, limit switches, or

similar emergency stop devices.

All such emergency stop devices shall be easily identifiable in the imme-

diate vicinity of such locations unless guarded by location, position, or guards.

Where the design, function, and operation of such conveyor clearly is not

hazardous to personnel, an emergency stop device is not required.

The emergency stop device shall act directly on the control of the con-

veyor concerned and shall not depend on the stopping of any other equip-

ment. The emergency stop devices shall be installed so that they cannot be

overridden from other locations.

D) Inactive and unused actuators, controllers, and wiring should be removed

from control stations and panel boards, together with obsolete diagrams, indi-

cators, control labels, and other material which serve to confuse the opera-

tor.

SAFETY DEVICES

A) All safety devices, including wiring of electrical safety devices, shall be

arranged to operate in a “Fail-Safe” manner, that is, if power failure or failure

of the device itself would occur, a hazardous condition must not result.

B) Emergency Stops and Restarts. Conveyor controls shall be so arranged

that, in case of emergency stop, manual reset or start at the location where

the emergency stop was initiated, shall be required of the conveyor(s) and

associated equipment to resume operation.

C) Before restarting a conveyor which has been stopped because of an

emergency, an inspection of the conveyor shall be made and the cause of

the stoppage determined. The starting device shall be locked out before any

attempt is made to remove the cause of stoppage, unless operation is neces-

sary to determine the cause or to safely remove the stoppage.

Refer to ANSI Z244.1-1982, American National Standard for Personnel

Protection – Lockout/Tagout of Energy Sources – Minimum Safety

Requirements and OSHA Standard Number 29 CFR 1910.147 “The Control

of Hazardous Energy (Lockout/Tagout).”

OPERATION

Before conveyor is turned on, check for foreign objects that may have been

left inside conveyor during installation. These objects could cause serious

damage during start-up. After conveyor has been turned on and is operating,

check motors, reducers, and moving parts to make sure they are working

freely.

MAINTENANCE

The drive chain is pre-lubricated from the manufacturer by a hot dipping

process that ensures total lubrication of all components. However, continued

proper lubrication will greatly extend the useful life of every drive chain.

Drive Chain lubrication serves several purposes including:

• Protecting against wear of the pin-bushing joint

• Lubricating chain-sprocket contact surfaces

• Preventing rust or corrosion

For normal operating environments, lubricate every 2080 hours of operation

or every 6 months, whichever comes first. Lubricate with a good grade of

petroleum or synthetic oil (i.e., Shell Rotella or Mobil 1). For best results,

always use a brush to generously lubricate the chain. The proper viscos-

ity of lubricant greatly affects its ability to flow into the internal areas of the

chain. Refer to the table below for the proper viscosity of lubricant for your

application.

The drive chain’s lubrication requirement is greatly affected by the operating

conditions. For harsh conditions such as damp environments, dusty environ-

ments, excessive speeds, or elevated temperatures, it is best to lubricate

more frequently. It may be best, under these conditions, to develop a custom

lubrication schedule for your specific application. A custom lubrication sched-

ule may be developed by inspecting the drive chain on regular time intervals

for sufficient lubrication. Once the time interval is determined at which the

chain is not sufficiently lubricated, lubricate it and schedule the future lubrica-

tion intervals accordingly.

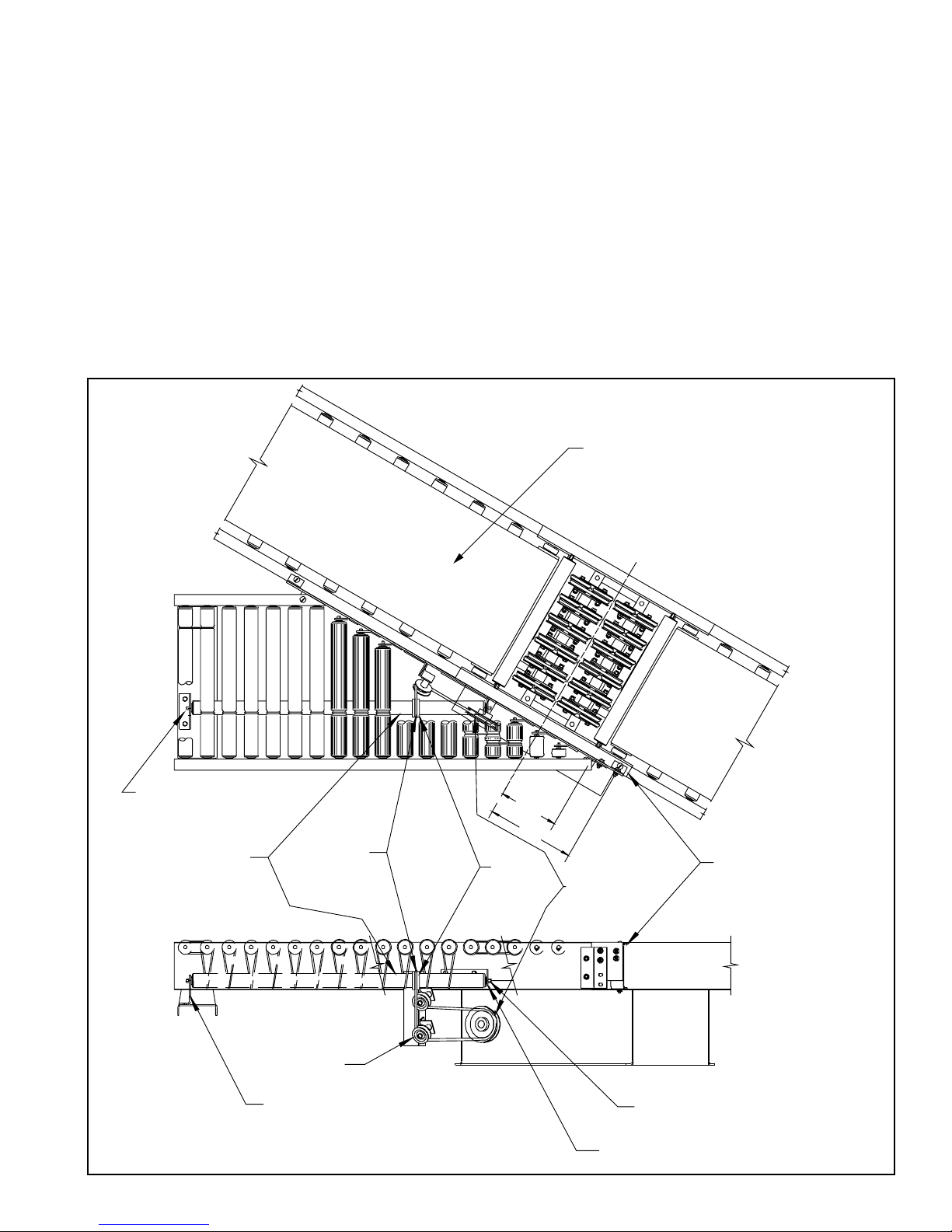

INSTALLING THE BELT

The conveyor drive belt has been pre-cut and the proper lacing attached at

the factory. Thread belt through conveyor per Figure 6B. Note that there

should be no air pressure on the pneumatic tensioner (if supplied). Pull belt

ends together and insert lacing pin. (Figure 6A). Adjust take-up to remove

slack from the belt.

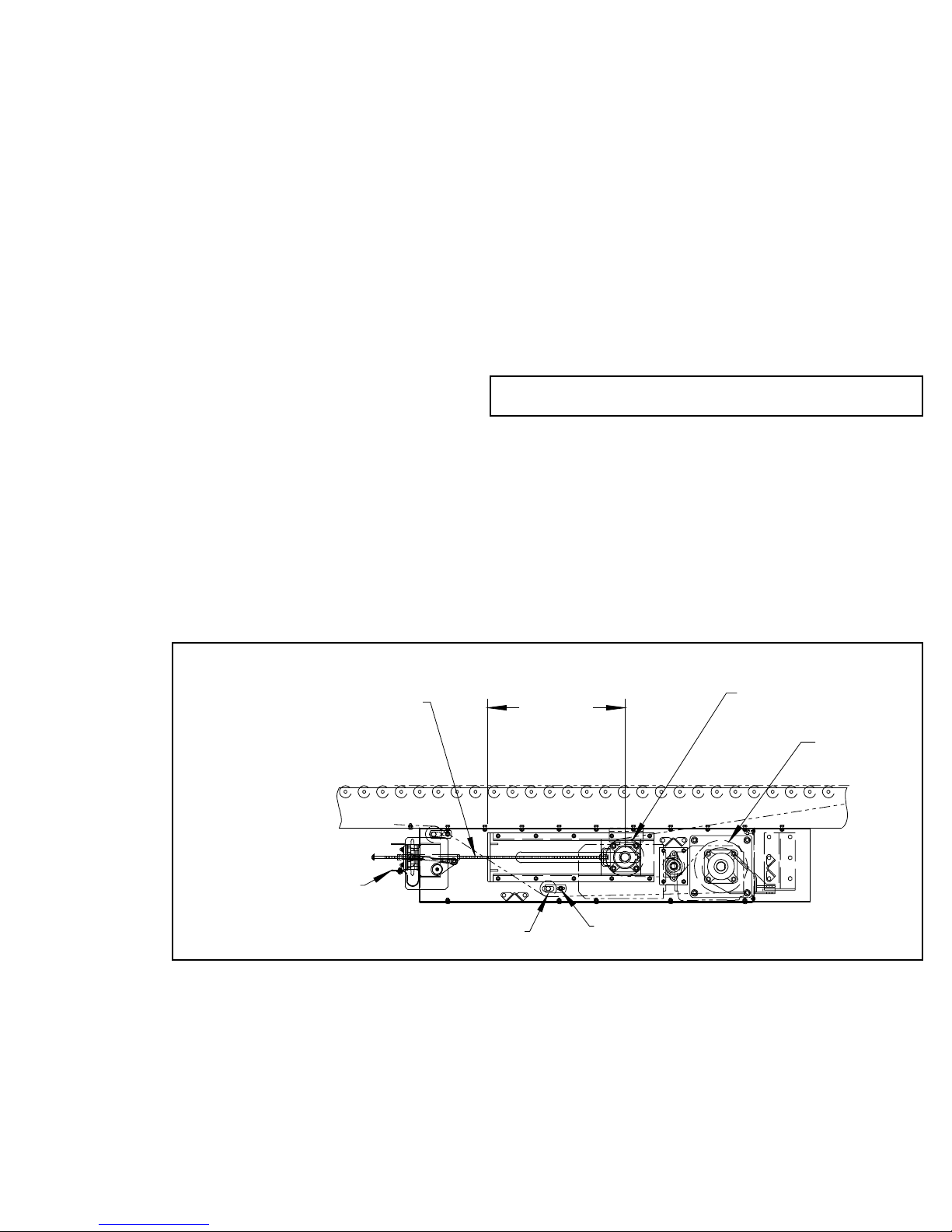

BELT TENSION

For maximum efficiency, maintain enough belt tension so drive pulley will

not slip when carrying the rated load. Belt tension should be adjusted with

the take-up pulley in the drive. (Figure 7) Keep pulley square with bed by

moving both take-up bolts an equal amount.

Pneumatic Tensioner (when supplied):

Initial Tension:

With no air pressure on tensioner, take up the belt until the unit runs and

the drive pulley does not slip (keeping pulley square). With unit turned

off, back the jam nuts off by a distance of 1/2”. Lock jam nuts at this loca-

tion. Starting at 10 psi, increase air pressure until the tensioner strokes

1/2” (measure gap between channel and UHMW block). Tensioner will now

have 2” of additional stroke and 1/2” of relief.

Resetting Tension:

When the tensioner approaches full stroke the take-up should be adjusted

until the tensioner is set at 1/2” again.

WARNING! Electrical controls shall be installed and wired by a qualified electrician.

Wiring information for the motor and controls are furnished by the equipment manu-

facturer.

CAUTION! Because of the many moving parts on the conveyor, all personnel in the

area of the conveyor need to be warned that the conveyor is about to be started.

Ambient Temperature

Degrees F SAE ISO

20-40 20 46 or 68

40-100 30 100

100-120 40 150

NOTE: If belt ends cannot be pulled together by hand, it may be necessary to loosen

take-up pulley (in drive) to minimum position or use a belt puller so lacing pin can be

easily inserted.

5