CST Berger Lasermark Wizard LM30 User manual

IInnssttrruuccttiioonnMMaannuuaall

MMaannuuaallddeeIInnssttrruucccciioonneess

MMaannuueelldd’’IInnssttrruuccttiioonnss

MMaannuuaalleeddiiIIssttrruuzziioonnii

BBeeddiieennuunnggssaannl

leeiittuunngg

IInnssttrruuççõõeessddeeUUttiilliizzaaççããoo

INSTRUCTION MANUAL

2 • LM30 Rotary Laser

Copyright © 2003-2005 CST/berger. All rights reserved. This document shall not be copied or

otherwise reproduced without CST/berger’s written consent. LaserMark® is a registered trade-

mark of CST/berger.

6

44

7

8

5

10

11

12

13

1

2

3

6

FFiigg..11

LM30 Rotary Laser • 3

2

3

4

1

7

6

5

8

Function Buttons

Clock-wise Head Positioning

Counter-lock-wise Head Positioning

Fast

Rotate

Slow

Rotate

Spot

Mode

Long

Sweep

Short

Sweep

CCW CW

RC 100

12345

Clock-wise Head Positioning

Counter-clock-wise Head Positioning

Fast

Rotate

Slow

Rotate

Spot

Mode

Long

Sweep

Short

Sweep

CCW CW

RC30

12345

Rotary Laser Level

Remote Control

1

23

FFiigg..22

FFiigg..55

FFiigg..33FFiigg..44

Thank you for purchasing the LaserMark® Wizard LM30 Rotary

Laser. Please read this manual thoroughly before operation.

The information contained herein is proprietary information of

CST/berger, and is subject to change without notice.

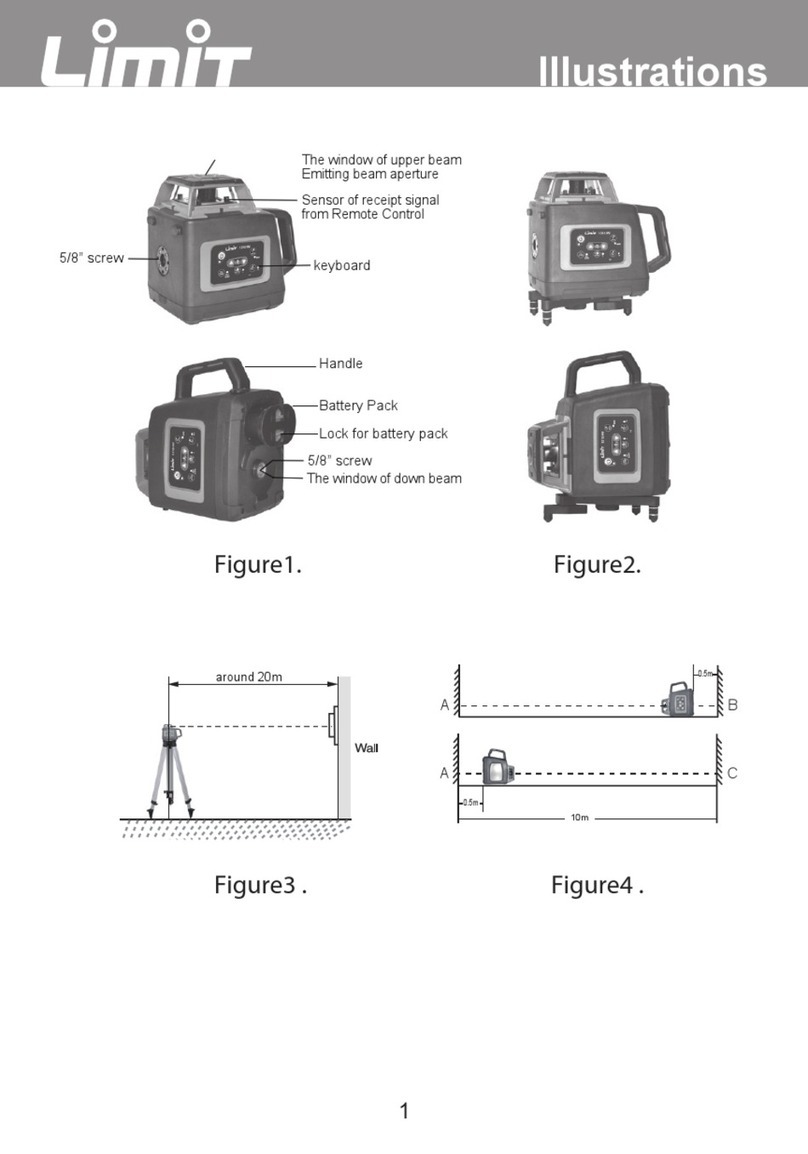

FEATURES (Fig. 1)

1. Laser Emitting Window (Plumb Beam) 2. Rotary Head

3. “Y” Level Vial 4. “X” Level Vial

5. “Y” Leveling Screw & Plumb Vial Leveling Screw 6. “X” Leveling Screw

7. Plumb Vial 8. Control Button

9. Laser Emitting Window (Level Beam) 10. Trivet

11. Battery Door Screw 12. Battery Door

13. Base with two 5/8” - 11 Mounting Thread

CONTROL BUTTON OPERATION (Fig.2)

1. POWER/CONTROL BUTTON - LEDs indicate operation mode

2. PRESS CONTROL BUTTON ONE TIME to turn unit on; rotation begins in

FAST” Speed (approx. 600 RPM).

3. PRESS TWO TIMES for “SLOW” Speed (approx. 150 RPM).

4. PRESS THREE TIMES to “STOP” rotary head (laser remains lit).

5. Press FOUR TIMES to use Long Sweep

6. Press FIVE TIMES to use Short Sweep

7. Low Battery Indication Light

8. Remote Control Window

PRESS CONTROL BUTTON SIX TIMES to turn unit off (no LED’s remain lit and

the laser is OFF).

4 • LM30 Rotary Laser

EN

LASER SAFETY

The use of controls, adjustments, or the performance of procedures other

than those specified herein may result in hazardous radiation exposure.

Do not stare into the laser beams. Do not disassemble the instrument or

attempt to perform any internal servicing.

Repair and servicing of this laser are to be performed only by CST or author-

ized service centers.

This laser complies with all applicable portions of title 21 of the Code of

Federal Regulations set by: the Dept. of Health, Education, and Welfare; the

Food and Drug Administration; the Center for Devices; and the Bureau of

Radiological Health.

The laser LM30 has also been tested and complies with the CE certification

requirements set forth in the EC regulations 89/336/EEC and EN 61000-6-1

(EN50082-1), EN 61000-6-3 (EN50081-1) and IEC 60-825-1.

OPERATION

Basic Leveling

As with any level referencing instrument, checking calibration before each

use is recommended.

1. Set the instrument on any smooth surface, or mount to a 5⁄8" x 11 tripod

and adjust to desired height.

2. Use the leveling screws and level vials to level the instrument. Each lev-

eling screw controls the vial opposite the screw (the front leveling

screw controls the “Y” axis, and the side leveling screw controls the

“X” axis).

LM30 Rotary Laser • 5

NOTE: The more accurately the vial bubbles are centered, the more accurate

the laser beam will be for referencing level.

3. Turn power on and press the control button once for “FAST” speed

(ideal for use outdoors with a laser detector), or twice for “SLOW”

speed (ideal for indoor use). You have created a highly visible, level ref-

erence line (Fig. 3).

Plumbing

1. On a flat surface, place the instrument on its back using the built-in triv-

et (control button facing upward).

2. Level the instrument by viewing the plumb vial and turning the front lev-

eling screw until the plumb vial bubble is centered (Fig. 4).

3. Turn power on and press the control button until you reach your desired

speed. You have created a highly visible, plumb reference line!

Stopping the Rotary Head

It is possible to stop rotation of the head in order to manually direct the laser

dot towards a target, much like a straight-line laser.

1. Turn the unit on by pressing the control button.

2. Press two more times until the “STOP” LED is lit. The rotary head will

stop turning.

3. Align the laser beam to your target by turning the rotary head manually.

Sweep Modes (Point & Shoot Scanning)

The LM30’s Sweep Modes create an easily visible laser “chalk line” that you

can direct by manually turning the rotary head.

This is especially useful on job sites where you must contain the laser’s loca-

tion to avoid interference with other laser users or laser detectors on site.

Also, this feature is very useful for extending the range of the visible beam.

You may use this feature in either a level or plumb position.

6 • LM30 Rotary Laser

1. Turn the unit on by pressing the control button.

2. Press three more times until the “LONG SWEEP” LED is lit. The rotary

ad will quickly scan back and forth to create a laser “chalk line”.

3. To direct the sweep toward your target, grab the rotary head to stop its

movement, and wait for rotation pressure to relax (normally within a

few seconds).

Rotate head to your desired position and release.

4. Length of the chalk line will vary depending on the distance of the

Wizard from your working surface; the angle of the long sweep is

approximately 45°. To create a shorter, faster sweep, press the control

button once more (”SHORT SWEEP“ LED will light); the angle of the

short sweep is approximately 22°.

Note: The Sweep Function of this unit is intended for indoor use only. Use of

the LM30 in direct sunlight may result in erratic operation of the Sweep

Function.

Use of the LM30 in direct sunlight will not affect any other functions

Remote Control RC30 - (Fig. 5)

Note: Remote control is included with LM30 Interier packages.

The remote controls Fast Rotation Speed, Slow Rotation Speed, Spot Mode,

Long Sweep, Short Sweep, and can be used up to a maximum of 100 feet (30

m) away from the unit. The user must face the control panel for proper oper-

ation of the remote. Requires 2 AA Alkaline batteries.

1. Operates same as the single button on unit

2. Rotate laser beacon counter-clock-wise when in sweep or spot mode

3. Rotate laser head clock-wise when in sweep or spot mode

LM30 Rotary Laser • 7

APPLICATIONS (Fig.6)

Installing drop ceiling and grid and tiles. Use with Wall/Ceiling Mount

INDOOR LEVELING/PLUMBING: Window Frames, Cabinets & Shelves, Doors

& Windows, Erecting Walls & Partitions, Aligning 90° Joints & Edges, Floors,

Tile Work.

OUTDOOR LEVELING/PLUMBING: Porches & Decks, Fencing, Flagpoles,

Batterboards, Landscaping.

POWER

NiCad or Nimh rechargeable batteries do NOT work well in a Laser Level as

their operating voltage is too low. We recommend that only alkaline batteries

be used in your Laser Level. Plain carbon batteries can leak either fluid or

corrosive gas, both of which can damage the Laser Level.

It should be noted that the electronic switch in the Laser. Your LaserMark®

Wizard will provide approximately 60 hours of intermittent use.

The “Low Battery” LED will light when the batteries’ voltage falls below an

optimal level.Also, if your Wizard fails to emit laser beams, but still has func-

tioning LEDs and rotation, your batteries may be low; try replacing the batter-

ies before contacting a service center.

Replacement batteries must be all new batteries; alkalines provide the best

performance.

Replace the batteries as follows:

1. Remove the battery cover by turning the battery cover screw counter-

clockwise.

2. Remove the old batteries and replace with four new “C” cell batteries

as illustrated (Fig. 7), and replace the battery cover.

NOTE: Do not mix old and new batteries. Replace all batteries at the same

time with new batteries. Remove batteries before storage of the instrument

.

8 • LM30 Rotary Laser

CALIBRATION

All Laser Levels are calibrated during assembly and Q.A., howeverLaserLevel

owners should always check the calibration of the unit before use as the

settings may have changed with time or during transportation. It is also wise

to recheck the calibration of the Laser Level at regular intervals and also

prior to any critical measurements being performed. A 0.059"(1.5mm) Allen

key will be required to adjust the screws on the two leveling vials, and a

5/64” (2mm) one to adjust the LD vial.

Checking Horizontal Rotation Error

1. Mount and level the LaserMark® Wizard on a tripod and place approxi-

mately 50 feet (15m) away from a wall. Face the front (control button) to

the wall (Fig.8).

2. Turn power on and place the unit in “STOP” mode.

3. Manually rotate the laser beam onto the wall and mark as point A.

4. Loosen the Wizard from the tripod and rotate the instrument 180° so

that the back (battery side) now faces the wall.

Secure and re-level the instrument.

5. Again rotate the laser beam onto the wall and mark its position as point

B. No adjustment is necessary if the vertical difference between points

A and B is 1⁄8 inch (3mm) or less. Otherwise, adjust as follows.

Correcting Horizontal Rotation Error

1. Adjust the “Y” leveling screw until the laser beam rests midway

between A and B (Fig. 8). This will cause the “Y” vial bubble to shift

from center. Clockwise rotation will raise the beam; counterclockwise

rotation will lower the beam.

2. Center the “Y” vial bubble by adjusting the vial leveling screws with a

1.5mm hex key.

3. Recheck the accuracy of horizontal rotation by repeating steps 1-5 in

LM30 Rotary Laser • 9

section”Checking Horizontal Rotation Error”. Readjust as

necessary.Repeat the above checking and adjusting procedures using

the left and right sides of instrument, adjusting the “X” leveling screw

and “X” vial as necessary.

Checking Vertical Rotation Error

1. Set the instrument on its trivet (control button upward) on a floor

approximately 100 feet (30m) from the base of a wall. The right side of

the instrument should face the wall. Level the unit by adjusting the “Y”

leveling screw.

2. Turn power on and place the unit in “STOP” mode.

3. Mark a control point “A” on the wall (Fig. 9). Turn the rotary head manu-

ally until the laser beam hits point A on the wall.

4. Turn the rotary head to move the laser beam 30 feet (9m) upward on the

wall and mark this as point B.

5. Turn the instrument 180° and align the beam to point A, re-leveling if

necessary (Fig. 10).

6. Turn the rotary head to move the laser beam to the same height as point

B, and mark as point C.

No adjustment is necessary if the difference between points B and C is 1⁄8

inch (3mm) or less. Otherwise, adjust as follows.

Correcting Vertical Rotation Error

1. Adjust the “Y” leveling screw until the laser beam rests midway

between points B and C. This will cause the plumb vial bubble to shift

from center.

2. Center the plumb vial bubble by adjusting the vial leveling screws with a

5/64”(2mm) hex key.

3. Recheck the accuracy of vertical rotation by repeating steps 1-6 in sec-

tion”Checking Vertical Rotation Error”. Readjust as necessary.

10 • LM30 Rotary Laser

SETTING UP

Correct set-up of any manual Laser Level is critical to the operation of the

Level. These Laser Levels do not adjust themselves automatically. The accu-

racy of the job depends entirely upon how well the unit has been set-up. An

error of only 0.02" (0.5mm) at the top of the tripod becomes an error of 4" at

65 feet (100 mm at 20 meters). In order to achieve the accuracy required

some special precautions should be observed.

1. The head of the Laser Level is fitted with two engineering grade spirit lev-

eling vials which are extremely accurate and very sensitive. When the Level

is being set-up the bubbles move quite slowly and may even stick inside the

vial. This is called stiction. The solution is to lightly tap the non-rotating part

of the Level with the tip of a finger until the bubble ceases to move.

2. When attaching the Laser Level to the tripod, the instrument fastening

screw should not be over-tightened. If the screw is tightened excessively

then the trivet base will become distorted and over a period of time the plas-

tic material of the trivet will relax, particularly if the day is hot, causing the

setting of the Level to change. In extreme cases it is possible to pull the cen-

tre insert out of the trivet.

MAINTENANCE

Always clean the instrument after use. Use a soft, dry cloth to remove any

dirt or moisture from the instrument. Store the unit in its case when not in

use. Batteries should be removed before long-term storage.Do not use ben-

zene, paint thinner, or other solvents to clean the instrument.

ENVIRONMENT PROTECTION

Recycle raw materials instead of disposing as waste.The machine, acces-

sories and packaging should be sorted for environmentalfriendlyrecycling.

Do not throw used batteries into house waste, fire or water but

dispose of in an environmentally friendly manner according to the

applicable legal regulations.

LM30 Rotary Laser • 11

12 • LM30 Rotary Laser

SPECIFICATIONS

AApppprrooxxiimmaatteeRRoottaattiioonnSSppeeeedd::600 RPM–OUTDOOR; 150 RPM–INDOOR.

When using optional detector, highest

RPM mode is recommended.

HHoorriizzoonnttaallAAccccuurraaccyy::1⁄4" at 100 feet (6mm at 30m)

VVeerrttiiccaallAAccccuurraaccyy::15/32” at 100 feet (12 mm at 30 m)

RRaannggee::Up to 200 feet (60m) diameter interior,

up to 800 feet (240m) diameter exterior

with optional laser detector

LLaasseerrDDiiooddee::635nm

LLaasseer

rCCllaassss::3R

LLeevveell&&PPlluummbbVViiaallSSeennssiittiivviittyy::Level, 5-8 minutes; plumb, 15 minutes

MMoouunnttiinnggSSccrreeww::5⁄8" x 11 for standard tripods

WWeeiigghhtt::3.6 lbs. (1.6kg) with batteries

PPoowweerr::Four “C” cell batteries provide approxi-

mately 60 hours of intermittent use

Specifications subject to change without notice.

LM30 Rotary Laser • 13

UNIVERSAL LASER DETECTOR

Introduction

The Universal Laser Detector aids in locating and targeting a visible or invisi-

ble beam emitted by a rotary laser; perfect for use in outdoor conditions,

where sunlight and distance may make locating the beam more difficult.

Features (Fig. A)

1. LCD readout window 2. Speaker

3. Beam capture window 4. Power ON/OFF

5. Beam resolution 6. Volume ON/OFF

7. LCD readout window (LD-400 and LD-120 only) 8. Battery door

Operation

1. Turn on the unit by pressing the ON/OFF pad. The LCD symbols will

momentarily flash (Fig. B).

2. Expose the beam capture window of the laser detector towards the

direction of the rotating laser.

3. Slowly move the laser detector in an upward and downward direction

until the LCD beam indicator arrows appear and/or a pulsing audio sig-

nal is heard. Select the desired Beam Resolution, according to the job

conditions and the precision required (to see the available Resolutions,

please refer to the Specs Table).

4. Move the detector upward when the low beam indicator light is lit (with

volume on, a short pulsing audio tone is heard). Move the detector

downward when the high beam indicator arrow is lit (with volume on, a

long pulsing audio tone is heard). When the beam is level, the level

beam indicator line will be lit and a solid audio tone will be heard.

If the detector is not struck by a laser beam after 5-8 minutes, the detector

will automatically shut itself off to preserve battery life.

Turn the unit back on using the power button.

14 • LM30 Rotary Laser

Special features

The laser detector includes a rod clamp which allows to mount the detector

onto square, round or oval sighting rods.

The detectors are gasket sealed for water and dust protection. Remove any

moisture or dirt with a soft, dry cloth.

Do not use aggressive cleaning agents or solvents. Remove batteries before

storage of the instrument.

The LCD display of the detector LD-400 has seven distinct channels of infor-

mation, indicating the position of the detector in the plane of laser light, as

indicated in Fig. C (the detectors LD-120 and LD-100N have three).

As you move the detector closer to the center, the arrows fill in to indicate

the laser position.

The detector has a unique memory feature, which preserves the last position

of the laser beam if the detector is moved out of the plane of laser light, as

well as built in electronic filtering for bright sunlight and electromagnetic

interference.

The detector LD-400 has three speaker selections (Off, Loud (105dBA) and

Louder (125+ dBA)), whereas the models LD-120 and LD-100N have only two

(Off and On).

Power

A 9-volt battery will provide up to 3 months of typical usage. When the unit is

turned on and the low battery symbol remains lit, the battery should be

replaced.

Specifications

Note: Sensitivity values based on standard conditions with most lasers; may

vary slightly due to make, manufacturer, beam size, or working conditions.

LM30 Rotary Laser • 15

DDeessccrriippttiioonnLLDD--440000LLDD--112200LLDD--110000NN

Dimensions 6.6” H x “ W x 1” D (169mm x 76mm x 25mm)

Weight 10 oz. (275g)

Range Up to 800-ft (305m) Radius with LM30

Beam Resolution *

Fine ±0.75mm

Medium ±1.5mm

Wide ±3mm

Medium ±1.5 mm

Wide ±3 mm

Medium ±1.5mm

Wide ±3mm

Readout LCD, 2 windows LCD, 2 windows LCD, 1 window

Power One 9-volt battery provides 3 months of typical usage

16 • LM30 Rotary Laser

Warranty

One Year Warranty. CST/berger,

a division of Stanley Works

, warrants this

electronic measuring tool against deficiencies in material and workmanship

for a period of one year from the date of purchase. Deficient products will

be repaired or replaced at CST/berger's option. Proof of purchase is

required.

For warranty and repair information, contact:

YYoouurrLLooccaallDDiissttrriibbuuttoorr,,oorrCCSSTT//bbeerrggeerr..

This Warranty does not cover deficiencies caused by accidental damage,

wear and tear, use other than in accordance with the manufacturer's

instructions or repair or alteration of this product not authorized by

CST/berger.

Repair or replacement under this Warranty does not affect the expiry date of

the Warranty. To the extent permitted by law, CST/berger shall not be liable

under this Warranty for indirect or consequential loss resulting from defi-

ciencies in this product.

Agents of CST/berger cannot change this warranty. This Warranty may not

be varied without the authorization of CST/berger.

This warranty may provide you with additional rights that vary by state,

province or nation.

IIMMPPOORRTTAANNTTNNOOTTEE: The customer is responsible for the correct use and

care of the instrument. Moreover he is completely responsible for checking

the job along its prosecution, and therefore for the calibration of the instru-

ment. Calibration and care are not covered by warranty.

Subject to change without notice

Gracias por haber escogido nuestro Laser LM30.

CARACTERISTICAS (Fig. 1)

1 Rayo laser vertical (plomada) 2 Cabeza rotatoria

3. Burbuja horizontal eje “Y” 4 Burbuja horizontal eje “X”

5 Tornillo nivelación eje “Y” y plomada (vertical) 6 Tornillo nivelación eje “X”

7 Burbuja vertical 8 Botón de control

9 Rayo laser horizontal (nivelación) 10 Soporte

11 Tornillo de la tapa 12 Tapa de las pilas

13 Soporte base con dos roscas 5/8” - 11

FUNCIONAMIENTO DEL BOTÓN DE CONTROL (Fig. 2)

1. BOTÓN DE CONTROL – los LEDs indican la función seleccionada2.

Presionar UNA VEZ para encender la unidad; la rotación comienza en

velocidad de “EXTERIOR” (aprox. 600 RPM)

3. Presionar DOS VECES para seleccionar la velocidad de “INTERIOR”

(aprox. 150 RPM)

4. Presionar TRES VECES para parar la cabeza rotatoria (el láser per-

manece encendido)

5. Presionar CUATRO VECES para seleccionar el “barrido largo”

6. Presionar CINCO VECES para seleccionar el “barrido corto”

7. Indicación de carga de las pilas

8. Ventana de recepción del mando a distancia

Presionar SEIS VECES para apagar la unidad (ningún LED permanece encen-

dido)

LM30 Rotary Laser • 17

E

SEGURIDAD Y ESPECIFICACIONES

Es posible trabajar con el aparato sin peligro, sólo después de haber leído

atentamente las instrucciones para el uso y las advertencias de seguridad, y

siguiendo estrictamente las instrucciones.

El uso de instrumentos opticos, controles, ajustes o procedimientos de fun-

cionamiento distintos a los especificados en el presente manual pueden

provocar una exposicion a radiación peligrosa

No mirar hacia el rayo. No apuntar el rayo láser hacia otras personas. No

desmontar el instrumento, ni intentar hacer ningúna reparación. La

reparación y el mantenimiento de este láser deben ser realizados solamente

por CST o centros de servicio autorizados.

El equipo cumple con todas las especificaciones del artículo 21 del Código

de Regulación Federal (U.S.A.) el Departamento de Sanidad, Educación,

Alimentación y del Centro para la Salud Radiológica.

El láser LM30 también cumple con las especificaciones CE según las normas

89/336/EEC,EN 61000-6-1 (EN50082-1),EN 61000-6-3 (EN50081-1) y IEC 60-825-1

Copyright© 2003-2005 CST/berger. Derechos reservados.

Toda esta información es propiedad de CST/berger .

Este documento no debe ser copiado o reproducido sin el consentimiento

escrito de CST/berger. LaserMark® es una marca registrada de CST/Berger.

18 • LM30 Rotary Laser

FUNCIONAMIENTO

Nivelación

Como para cualquier instrumento de nivelación, se aconseja controlar la cal-

ibración del instrumento antes del trabajo (ver capítulo “CALIBRACIÓN”).

1. Colocar el LM30 sobre cualquier superficie lisa o montarlo en un

trípode estándar con rosca de 5/8” - 11.

2. Utilizar los tornillos de ajuste y las burbujas de nivelación para nivelar

el instrumento. Cada tornillo de nivelación controla la burbuja opuesta

al tornillo (el tornillo nivelador frontal controla el eje “Y”, y el tornillo

nivelador lateral controla el eje “X”).

Nota: Cuanto más exactamente centradas estén las burbujas, más precisa

será la señal del láser para el nivel de referencia. Asegurar que las burbujas

están estables.

3. Encender el láser y presionar una vez el botón de control para con-

seguir la velocidad “alta” (ideal para trabajar en el exterior con un

receptor láser), o dos veces para conseguir la velocidad “baja” (ideal

para trabajar en el interior). De esta forma se ha obtenido una línea de

referencia a nivel muy visible (Fig. 3).

Plomada

1. Sobre una superficie plana, colocar el láser sobre la parte posterior uti-

lizando el soporte (botón de control hacia arriba).

2. Nivelar el instrumento controlando la burbuja de la cara superior medi-

ante el tornillo nivelador “Y” (superior) hasta que la burbuja esté cen-

trada (Fig. 4).

3. Encender la unidad y presionar el butón de control hasta que se

alcance la velocidad deseada. De esta forma se ha obtenido una línea

de referencia vertical a nivel muy visible.

LM30 Rotary Laser • 19

Parada de la cabeza rotatoria

Es possible interrumpir la rotación de la cabeza para dirigir manualmente la

señal del láser hacia el objetivo deseado, como en un nivel láser de línea.

1. Encender el láser presionando el botón de control.

2. Presionar dos veces más hasta que la señal “STOP” esté encendida. La

cabeza rotatoria dejará de girar.

3. Alinear la señal de láser hacia su objetivo girando la cabeza manual-

mente.

Funcionamiento del modo “barrido”

El modo “barrido” del láser LM30 crea una línea láser muy visible, que puede

ser dirigida girando manualmente la cabeza rotatoria. Esto es particular-

mente útil cuando hay que delimitar el área del rayo láser para evitar inter-

ferencias con otros láser o receptores en la obra. Además con esta función

se aumenta de una manera considerable la visibilidad del rayo láser. Se

puede utilizar esta función en horizontal y en vertical.

1. Encender el láser presionando el botón de control.

2. Presionar tres veces más hasta que la señal “barrido largo” esté

encendida. La cabeza rotatoria empezará a girar hacia un lado y hacia

el otro para crear una línea de “barrido”.

3. Para dirigir el barrido hacia su objetivo, coger la cabeza rotatoria con

suavidad para parar la rotación y esperar que el motor baje su fuerza

(normalmente unos segundos). Girar la cabeza hacia el objetivo desea-

do y soltarla. Esta operación debe hacerse con mucha suavidad para

no dañar la cabeza giratoria.

4. La longitud del barrido varia según la distancia entre el láser y su obje-

tivo; el ángulo del barrido largo es de aprox. 45°. Para crear un barrido

más corto y más veloz, presionar otra vez el botón de control (la señal

de “barrido corto” está encendida); el ángulo del barrido corto es de

aprox. 22°.

20 • LM30 Rotary Laser

Other manuals for Berger Lasermark Wizard LM30

1

Table of contents

Languages:

Other CST Laser Level manuals