EZT-550 Controller Manual

1

TABLE OF CONTENTS

1. Overview ................................................................................................................................. 4

1.1 Menu Bar Function Tree.......................................................................................................4

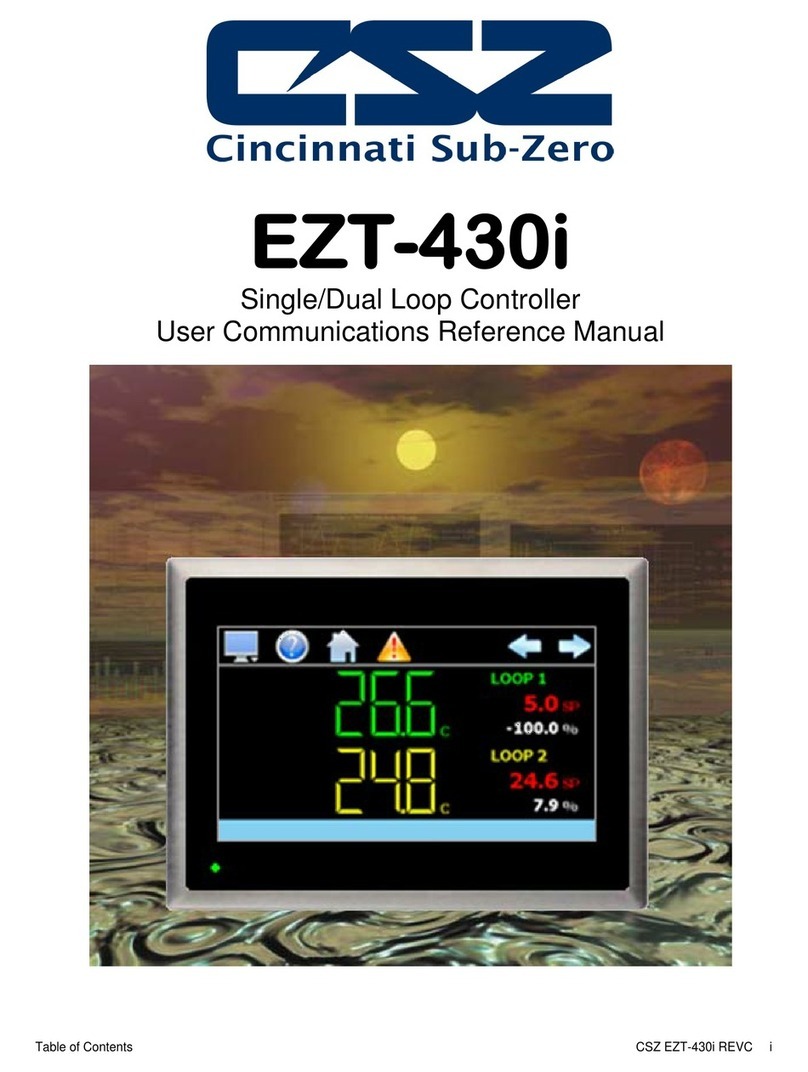

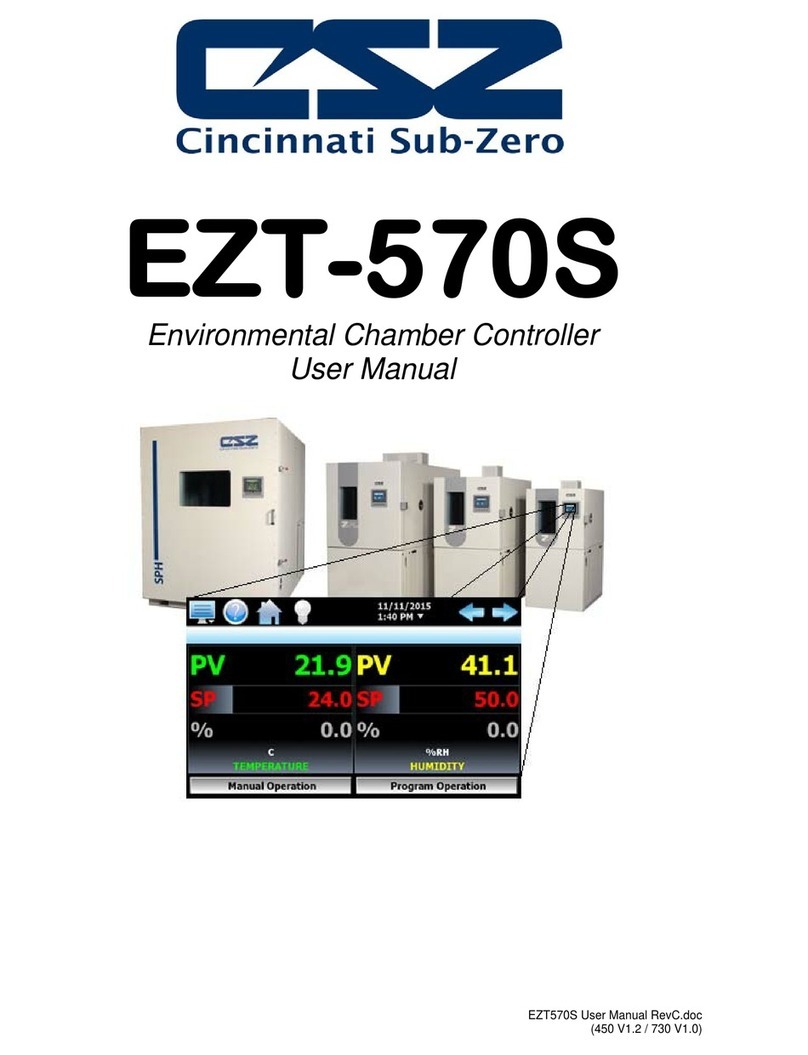

1.2 Touch Screen Interface ........................................................................................................ 6

2. Monitoring ................................................................................................................................. 7

2.1 Chamber Monitor .................................................................................................................. 7

2.2 Chamber Detail..................................................................................................................... 8

2.3 Trend Graph ......................................................................................................................... 9

2.4 Graphic Monitor .................................................................................................................. 10

2.5 System Alarms.................................................................................................................... 10

2.6 Profile Status View.............................................................................................................. 11

3. Single Setpoint Operation......................................................................................................... 13

3.1 Single Setpoint Adjustment ................................................................................................13

3.2 Event Control (Chamber On/Off) ........................................................................................ 14

3.2.1 Chamber Options................................................................................................... 15

4. Profile Operation........................................................................................................................ 17

4.1 Profile Create/Edit............................................................................................................... 17

4.2 Guaranteed Soak Limits ..................................................................................................... 21

4.3 Plot Profile .......................................................................................................................... 22

4.4 Start/Stop Profile................................................................................................................. 23

4.4.1 Hold/Resume a Profile........................................................................................... 24

4.4.2 Advance Previous/Next Step................................................................................. 24

5. Chamber Setup .......................................................................................................................... 25

5.1 Control Tuning .................................................................................................................... 25

5.1.1 How to Adjust Tuning Parameters......................................................................... 27

5.2 Device Under Test (DUT) ................................................................................................... 28

5.3 Event Tag Names ............................................................................................................... 29

5.4 Power Recovery .................................................................................................................30

5.5 Timer Setup ........................................................................................................................ 31

5.6 Defrost Settings .................................................................................................................. 33

6. Datalogging ............................................................................................................................... 34

6.1 Start/Stop Datalogging........................................................................................................ 34

6.2 View Log File ...................................................................................................................... 35

6.2.1 Deleting Log Files.................................................................................................. 38

7. System Maintenance ................................................................................................................. 39

7.1 Set Date/Time..................................................................................................................... 40

7.2 Level 1 (User) Security Options.......................................................................................... 41

7.2.1 Degrees C/F Selection .......................................................................................... 41

7.2.2 Maintenance Counters .......................................................................................... 42

7.2.3 Calibration.............................................................................................................. 43

7.3 Factory Security Options ....................................................................................................50

7.3.1 Setpoint Limits ....................................................................................................... 50

7.3.2 Startup Configuration............................................................................................. 50

8. File Access ............................................................................................................................... 51

8.1 Opening Files...................................................................................................................... 51