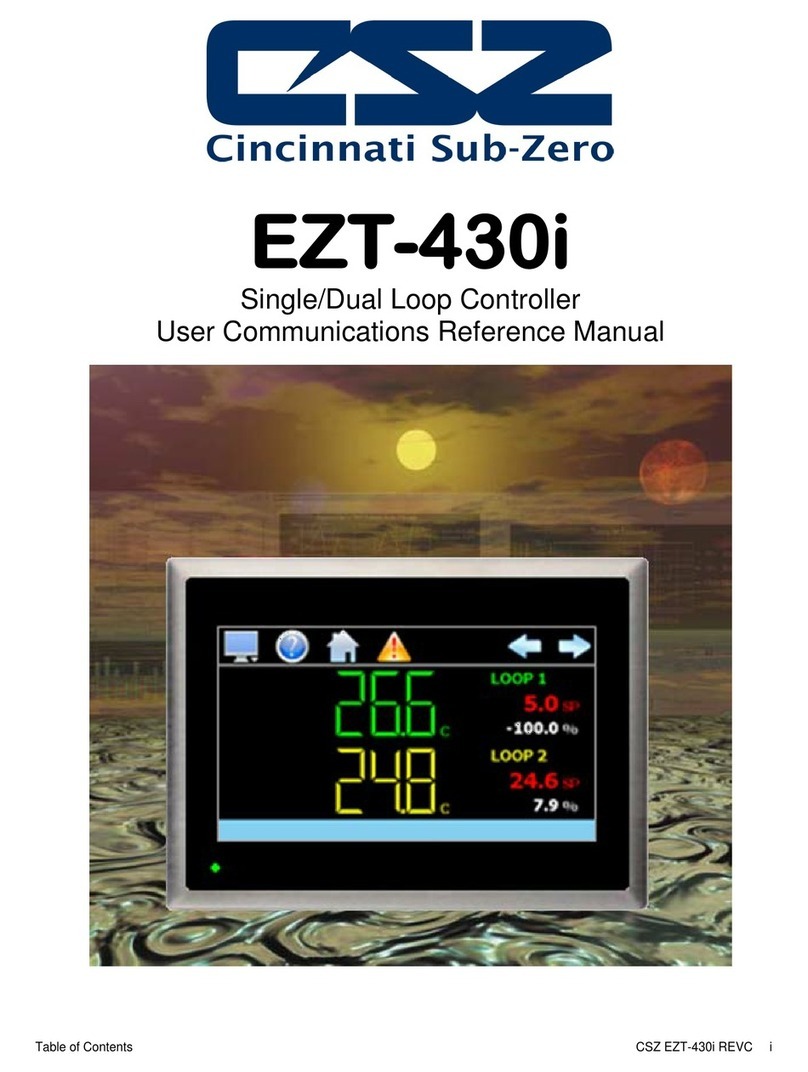

EZT-430i

Table of Contents CSZ EZT-430i i

1What is EZT-430i?.....................................................................................................1.1

1.1 Features...............................................................................................................................................1.1

2Configurator Overview .............................................................................................2.1

2.1 Configurator Menu ...............................................................................................................................2.2

3Configuring EZT-430i...................................................................................................1

3.1 Loop Setup..............................................................................................................................................1

3.2 Loop Address Utility................................................................................................................................2

3.3 User Communications.............................................................................................................................3

3.4 Loop Configuration..................................................................................................................................4

3.4.1 Input Sensor Selection .....................................................................................................................4

3.4.2 Input Unit Selection ..........................................................................................................................5

3.4.3 Decimal Point....................................................................................................................................5

3.4.4 Input Low/High Scale........................................................................................................................5

3.4.5 Input Filter.........................................................................................................................................6

3.4.6 Event Input Function.........................................................................................................................6

3.4.7 Low/High Setpoint Limits..................................................................................................................7

3.4.8 Output 1 Function.............................................................................................................................7

3.4.9 Output 1 Failure Transfer .................................................................................................................8

3.4.10 Output 1 ON-OFF Control Hysteresis ..............................................................................................9

3.4.11 Output 1 Cycle Time.........................................................................................................................9

3.4.12 Output 1 Low/High Limit Values .......................................................................................................9

3.4.13 Output 2 Function.............................................................................................................................9

3.4.14 Output 2 Failure Transfer ...............................................................................................................10

3.4.15 Output 2 Low/High Limit Values .....................................................................................................10

3.4.16 Output 3 Function...........................................................................................................................11

3.4.17 Output 3 Failure Transfer ...............................................................................................................11

3.4.18 Output 4 Function...........................................................................................................................11

3.4.19 Output 4 Failure Transfer ...............................................................................................................12

3.4.20 Output 4 Low/High Limit Values .....................................................................................................12

3.4.21 Output 4 Retransmit Low/High Scale .............................................................................................12

3.4.22 Alarm (1-3) Function.......................................................................................................................13

3.4.23 Alarm (1-3) Mode............................................................................................................................14

3.4.24 Alarm (1-3) Indication .....................................................................................................................15

3.4.25 Alarm (1-3) Setpoint .......................................................................................................................15

3.4.26 Alarm (1-3) Hysteresis....................................................................................................................15

3.4.27 Setpoint at Start of Automatic Program..........................................................................................16

3.4.28 Setpoint at End of Automatic Program...........................................................................................16

3.4.29 Power Fail Recovery ......................................................................................................................17

3.4.29.1 Enabling Holdback ...................................................................................................................18

3.5 Calibration.............................................................................................................................................20

3.6 Functions...............................................................................................................................................21

3.7 Startup View..........................................................................................................................................24

3.8 Alarm/Event Tagnames.........................................................................................................................25

3.8.1 Alarm Names..................................................................................................................................25

3.8.2 Event Names..................................................................................................................................25

3.9 Custom Name\Address.........................................................................................................................26