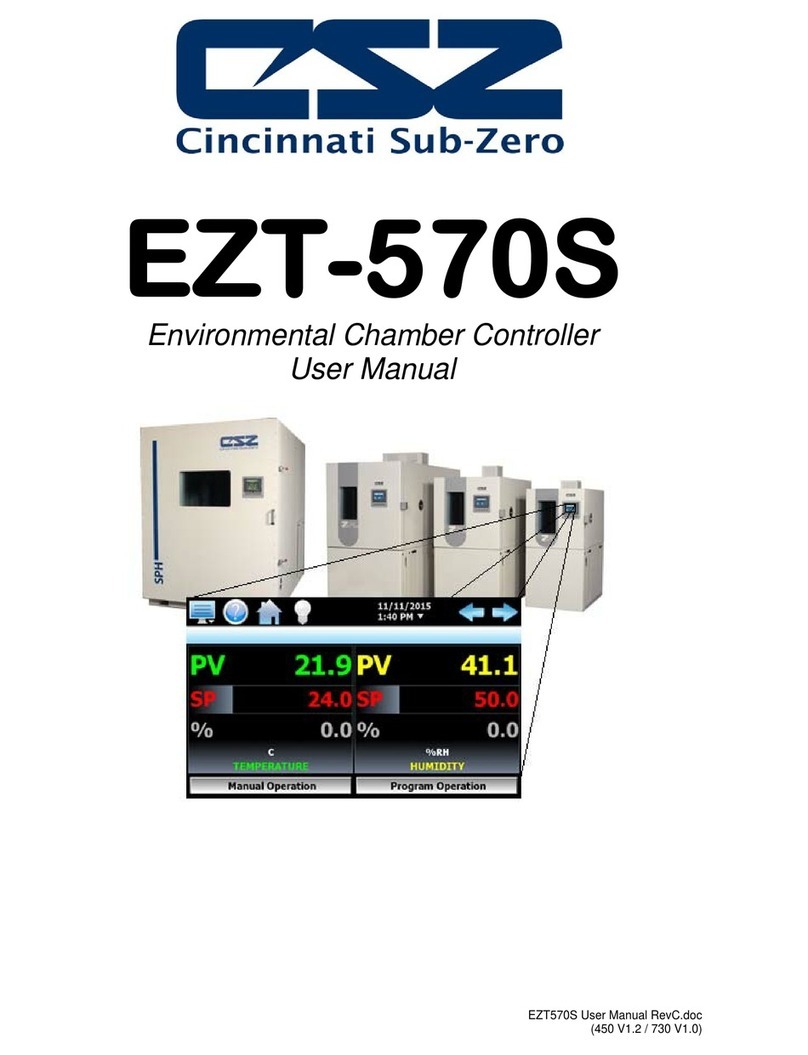

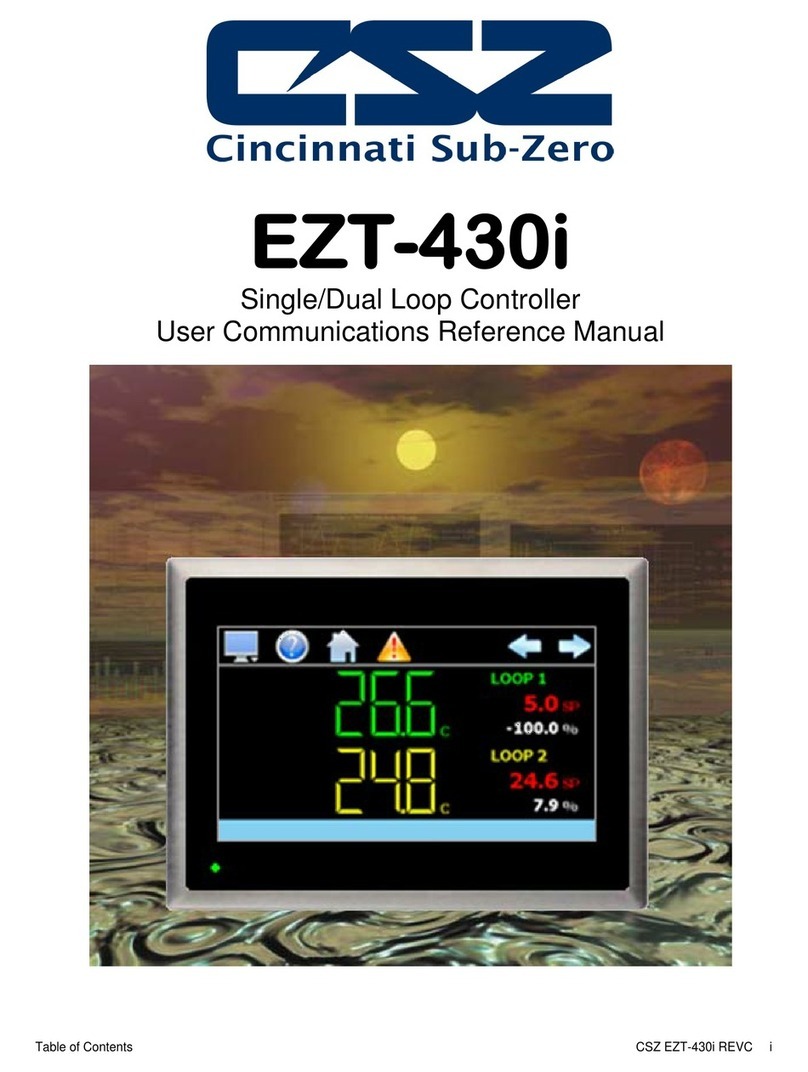

EZT-430i User’s Manual

TableofContents EZT-430iREVC i

1What is EZT-430i?.....................................................................................................1.1

1.1 Features...............................................................................................................................................1.1

2Installation.................................................................................................................2.1

2.1 Enclosure Guidelines...........................................................................................................................2.1

2.1.1 Locating the EZT-430i Touch Screen Interface.............................................................................2.2

2.2 Environmental Considerations.............................................................................................................2.2

2.3 Mounting Dimensions...........................................................................................................................2.2

2.3.1 EZT-430i Touch Screen Interface .................................................................................................2.2

2.3.2 EZT-430i Process Loop Controllers..............................................................................................2.4

3Wiring.........................................................................................................................3.1

3.1 Power Requirements............................................................................................................................3.1

3.1.1 Installing the Power-On Delay Relay.............................................................................................3.2

3.2 Connecting to the EZT-430i Interface..................................................................................................3.3

3.2.1 Process Loop Controller Communications....................................................................................3.4

3.2.2 User Serial Communications.........................................................................................................3.5

4Basic Operation.........................................................................................................4.8

4.1 OEM Configuration Options.................................................................................................................4.8

4.1.1 Loop 1/2 Monitor Mode..................................................................................................................4.8

4.2 Touch Screen Interface........................................................................................................................4.9

4.3 Menu Navigation................................................................................................................................4.10

4.3.1 Home Menu.................................................................................................................................4.11

4.3.1.1 Text Based Home Menu .......................................................................................................4.11

4.3.1.2 Icon/Slide Page Based Home Menu.....................................................................................4.12

4.3.2 Automatic Ramp/Soak Program Menu........................................................................................4.13

4.3.2.1 Text Based Program Menu...................................................................................................4.13

4.3.2.2 Icon/Slide Page Based Program Menu.................................................................................4.14

4.3.3 Device Settings Menu..................................................................................................................4.15

4.3.3.1 Text Based System Setup Menu ..........................................................................................4.15

4.3.3.2 Icon/Slide Page Based Device Settings Menu .....................................................................4.16

4.3.4 Offline Menu ................................................................................................................................4.16

4.3.4.1 Text Based Offline Setup Menu............................................................................................4.16

4.3.4.2 Icon/Slide Page Based Offline Menu....................................................................................4.17

4.3.5 Data Menu...................................................................................................................................4.18

4.3.5.1 Text Based Data Logging Menu ...........................................................................................4.18

4.3.5.2 Icon/Slide Page Based Log Menu.........................................................................................4.19

4.4 Notifications........................................................................................................................................4.20

4.5 Control Loops (Single Set point Operation).......................................................................................4.20

4.5.1 Single Loop View.........................................................................................................................4.21

4.5.2 Dual Loop View ...........................................................................................................................4.22

4.6 Event Control .....................................................................................................................................4.23

4.7 Process Monitoring ............................................................................................................................4.24

4.7.1 Charts..........................................................................................................................................4.24

4.7.1.1 Chart Setup...........................................................................................................................4.25

4.8 System Alarms...................................................................................................................................4.26

4.8.1 Alarm Monitor ..............................................................................................................................4.26

4.8.2 Alarm File.....................................................................................................................................4.27