CTA Optiplus 3 User manual

Operating manual

Optiplus 3

Heat pump controller

2Subject to technical changes © CTA 10/2016 www.cta.ch

Basic settings

No. Description Default

GK001 Language Setting German

GK002 Setting time zone Bern

Heating circuit 1

No. Description Default

HK101 Operating mode HC1 Frost pro-

tection (Off)

HK102 Comfort mode HC1 -

Phase 1 On (Hours) 6

HK103 Comfort mode HC1 -

Phase 1 On (Minutes) 0

HK104 Comfort mode HC1 -

Phase 1 Off (Hours) 22

HK105 Comfort mode HC1 -

Phase 1 Off (Minutes) 0

HK110 Comfort setpoint HC1 20

HK111 Reduced setpoint HC1 19

HK112 Frost protection setpoint

HC1 10

HK113 Slope heating curve HC1 0.8

HK114 Offset heating curve HC1 0

HK115 Heating limit heating circuit 17

Domestic hot water

No. Description Default

TW101 Operating mode DHW Off

TW102 DHW charging nominal set-

point - Phase 1 On (Hours) 22

TW103 DHW charging nominal set-

point - Phase 1 On (Minutes) 0

TW104 DHW charging nominal set-

point - Phase 1 Off (Hours) 4

TW105 DHW charging nominal set-

point - Phase 1 Off (Minutes) 0

TW110 Nominal setpoint DHW 51

TW111 Reduced setpoint DHW 40

TW112 Domestic water re-charge

hysteresis 6

TW113 Legionella temperature 60

TW115 Activation of the legionella

program Off

TW116 Legionella program day Fridays

TW117 Legionella program start time 2

Cooling circuit 1

No. Description Default

KK101 Operating mode CC1 Off

KK102 Operating mode CC1 -

Phase 1 On (Hours) 6

KK103 Operating mode CC1 -

Phase 1 On (Minutes) 0

KK104 Operating mode CC1 -

Phase 1 Off (Hours) 22

KK105 Operating mode CC1 -

Phase 1 Off (Minutes) 0

KK110 Room setpoint CC 1 24

KK115 Flow setpoint CC1 at 25°C

outside temperature 20

KK116 Flow setpoint CC1 at 35°C

outside temperature 18

KK117 Cooling limit CC1 at AT 24

3Subject to technical changes © CTA 10/2016 www.cta.ch

Program key – Returns to the start screen from any level.

(Key pressed for 3 seconds: Basic settings / Password entry) Esc/Back – Cancel entries as well as back to the

previous level. Arrow Up – Scroll back as

well as increase values.

Enter/Confirm – Selection of parameters, confirming

entries as well as calling up selected levels. Arrow Down – Scroll forwards

as well as reduce values.

Alarm key – Flashes when alarm is activated. Press in order to

access the alarm description and to RESET the alarms.

User

Settings for specialist personnel

TW115

TW116

TW117

TW101

TW102

TW103

TW104

TW105

TW110

TW111

TW112

TW113

HK113

HK114

HK115

HK101

HK102

HK103

HK104

HK105

HK110

HK111

HK112

Specialist

1

Home

1

Software

and OS

Version

Controller

type

2

GK001

GK002 4

Password

entry

3

Date

Time

3 Sec.

1

65

4

3

12

3

12

3

12

TW015

TW016

TW017

KK101

KK102

KK103

KK104

KK105

KK110

3

12

4Subject to technical changes © CTA 10/2016 www.cta.ch

Disclaimer

The manufacturer is not liable for damages on account of use contrary to the intended use. Liability of the manufac-

turer ceases furthermore:

if work is performed on the unit and its components contrary to the specifications in this operating manual.

if work is perfomed improperly on the unit and its components.

if work not described in this manual is performed on the unit and this is not expressly approved by the manufacturer

in writing.

if the unit or the components in the unit are modified, retrofitted or dismounted without the express written consent

of the manufacturer.

Copyright

Kindly read this first

This operating manual gives you important information about handling the unit. It is a part of the product and must

be kept ready to hand right next to the unit. It must be kept available during the entire life of the unit. It must be

handed over to subsequent owners of the unit.

Read this operating manual before starting any work on and with the unit. Particularly the safety chapter. Follow all

instructions completely and absolutely.

This operating manual may perhaps include descriptions, which may appear to be incomprehensible and unclear.

For queries and doubts, contact the factory customer service or the concerned on-site partner of the manufacturer.

Since this operating manual has been prepared for several types of units, parameters applicable for the relevant unit

type must be complied with. The operating manual is solely intended for personnel dealing with the unit. Treat all

constituent parts confidentially.

They are copyright protected. They may not be reproduced, transmitted, copied, saved in electronic systems or

translated into another language either partially or completely without the written consent of the manufacturer.

Copyright and disclaimer

© Bern CTA AG

Hunzikenstrasse 2

CH-3110 Münsingen

Telephone +41 (0)31 720 10 00

Fax +41 (0)31 720 10 50

www.cta.ch

5Subject to technical changes © CTA 10/2016 www.cta.ch

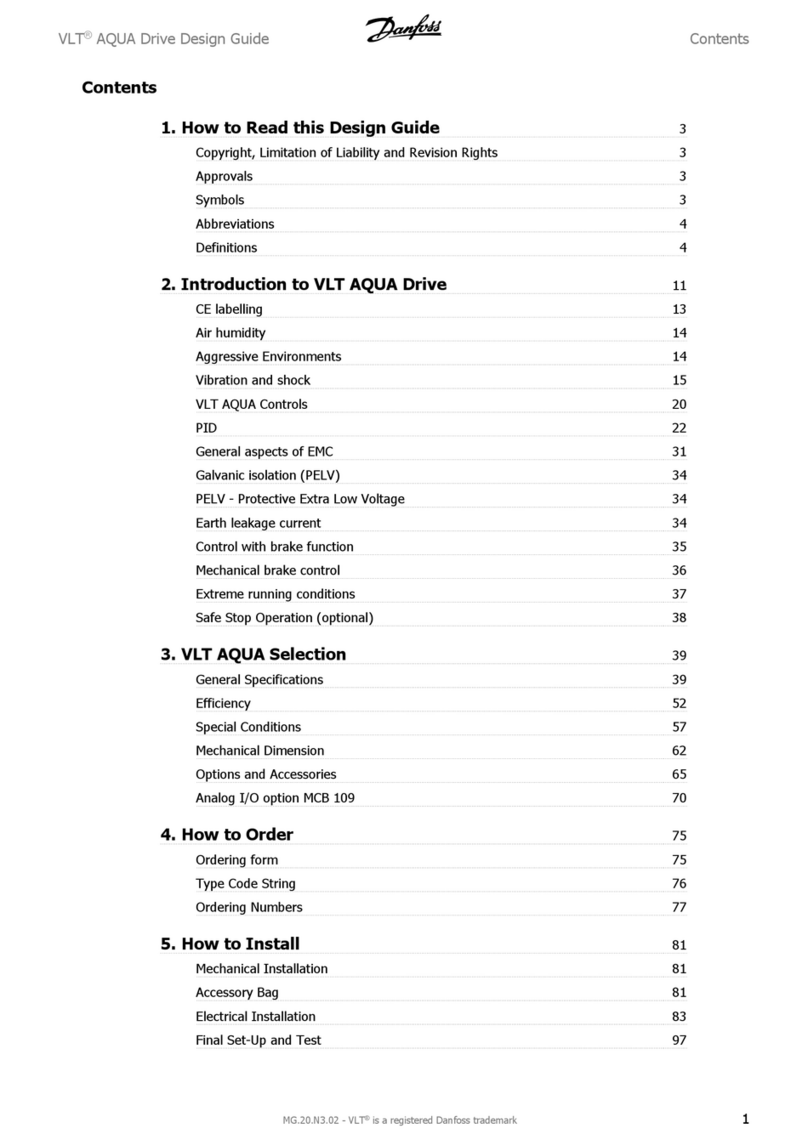

Table of contents

1 Safety 6

1.1 Classification of risks 6

1.2 Symbols used 6

1.3 Summary of risks 7

2 Intended use 8

2.1 Operation 8

2.2 Intended purpose 8

2.3 Customer service 8

2.4 Warranty / Guarantee 8

2.5 Disposal 9

2.6 Care of the unit 9

2.7 Maintenance of the unit 9

3 Basic information on operation 10

3.1 Control unit and keys 10

3.1.1 Start screen 11

3.1.2 General navigation 12

3.1.3 Change parameters 12

3.2 Heating mode 13

3.2.1 Operating mode Heating circuit 1 13

3.2.2 Heating circuit setpoint 14

3.2.3 Heating circuit heating curve 15

3.3 Domestic hot water mode 18

3.3.1 Operating mode DHW 18

3.3.2 Setpoints 20

3.3.3 Legionella program 20

3.4 Cooling mode 21

3.4.1 Operating mode Cooling circuits 21

3.4.2 Cooling circuit setpoints 22

3.4.3 Cooling characteristic curve 23

3.4.4 Cooling limit 23

3.5 Information 24

3.6 Settings 25

3.7 Error messages 25

3.7.1 Reset faults 25

3.7.2 Summoning the service organisation 25

3.8 Further functions 26

3.8.1 Software / regulation 26

3.8.2 Languages 26

3.8.3 Time, date and network information 26

3.8.4 Service level 26

4 Index 27

6Subject to technical changes © CTA 10/2016 www.cta.ch

The unit is safe to operate when operated in accordance with its designated use. Design and execution of the unit com-

plies with the current state of the art, all relevant EN regulations and all relevant safety regulations.

Each person working on the unit must have ready and understood the operating manual prior to starting work. This

also applies to persons who have already worked on such or similars units or have been trained by the manufactu-

rer.

1.1 Classification of risks

For imminent danger, which may lead to severe bodily injuries or death.

DANGER

For a potentially dangerous situation, which may lead to severe bodily injuries or death.

WARNING

For a potentially dangerous situation, which could lead to severe bodily injuries or death. May also be

used as warning for property damages.

CAUTION

For a potentially harmful situation.

Indicates important features for proper handling of the system.

NOTICE

1.2 Symbols used

This symbol warns of burns and scalds.

This symbol shows tips and information for optimum use of the system.

This symbol indicates inflammable substances.

This symbol warns of dangers, non-compliance of which may lead to extensive property damage.

This symbol indicates substances harmful to health.

This symbol indicates risk of injury to hands.

This symbol warns of risk from dangerous electric voltage.

Increased DANGER TO LIFE due to electric shock.

1 Safety

7Subject to technical changes © CTA 10/2016 www.cta.ch

Safety

This symbol indicates reuse and disposal of the unit.

This symbol is for advice which help save energy, raw materials and costs.

This symbol refers to other documents of the manufacturer.

This symbol refers to other sections in the operating manual.

1.3 Summary of risks

Safety guidelines stated here cover all important topics. Therefore, read the manual carefully and attentively.

All actions described in this manual must be performed by a technician according to the applicable legislation.

Wear appropriate protective equipment (safety gloves, safety goggles, etc.) when performing work related to instal-

lation, maintenance or servicing of the unit.

If you have queries related to the installation procedure or operation of the unit, contact your local dealer for advice

and information.

Improper installation or placement of the unit or accessories may lead to electric shock, short circuit, leakages, fire

and other damages. Use only accessories and optional equipment from CTA, which are specially developed for use

with the products, which are the subject of this manual and have these installed by a installer.

8Subject to technical changes © CTA 10/2016 www.cta.ch

2 Intended use

2.1 Operation

The existing manual serves correct installation and setting of the heat pump.

Likewise, this manual serves as a basis for the guarantee terms to be complied with by the operator, which is a

requirement for maintenance-free operation.

On violating the guarantee terms and after expiration of the guarantee period, the manufacturer of the heat pumps

does not undertake any responsibility for electrical defects. Guarantee lapses in case of interventions not explicitly

authorised and performed in violation of the existing manual. In-house safety regulations apply during the installati-

on.

The existing manual and the connection of the terminal plan of the heat pump are to be preserved with due diligen-

ce and provided to the specialist personnel if required.

For all types of repair works, the operator of the heat pump is instructed to contact his specialist partner, who ap-

points a technical customer service authorised by the manufacturer for the servicing of the heat pump.

Non-compliance of the above stated information may adversely affect the safety of the unit.

CAUTION!

The manufacturer does not undertake any liability for personal injury or property damage resulting due to direct

or indirect non-compliance of the existing manual.

CAUTION

2.2 Intended purpose

The unit must be used for the intended purpose only. That means in conjunction with a heat pump Optiheat Inverta:

for controlling and monitoring the heat pump

for regulating the heating groups

for regulating the hot water preparation

The unit must be operated only within its technical parameters.

2.3 Customer service

For technical information, kindly contact your expert technician or the concerned on-site partner of the manufactu-

rer.

2.4 Warranty / Guarantee

Warranty provisions and guarantee terms are in your purchase documents.

9Subject to technical changes © CTA 10/2016 www.cta.ch

Intended use

2.5 Disposal

CAUTION!

Reuse / disposal

When decommissioning the old unit on-site, comply with the applicable guidelines and standards for recycling,

reuse and disposal.

CAUTION

2.6 Care of the unit

You can use a damp cloth and standard cleaning products to clean the outer surfaces of the unit.

Do not use cleaning or care products that contain abrasives, acids and/or chlorine. Such products would irreparab-

ly damage the surfaces and could also cause technical damage to the unit.

2.7 Maintenance of the unit

The heating and heat pump controller requires no regular maintenance.

10 Subject to technical changes © CTA 10/2016 www.cta.ch

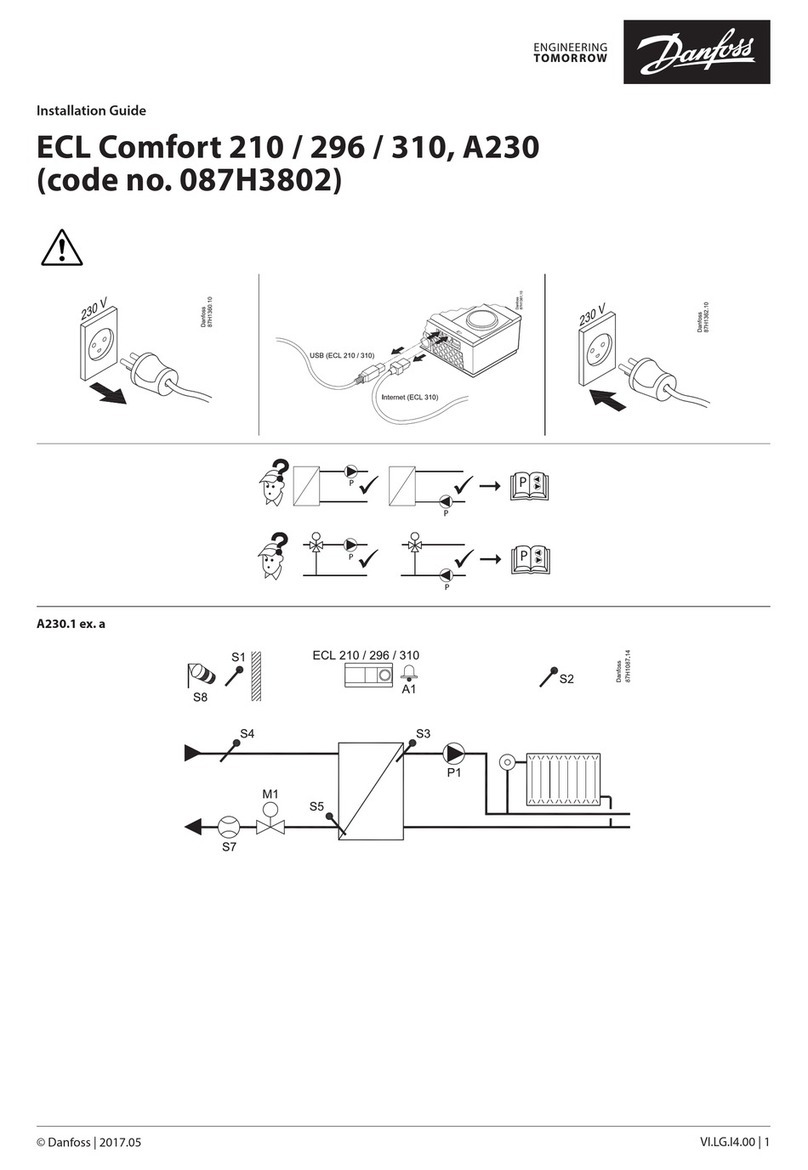

3.1 Control unit and keys

CTA controller with following features

• Display lights up, for status and function display

• Presetting standard program, setpoint, date, time

• Automatic switching between summer / winter time

• Preset standard time program for heating and domestic hot water preparation

• Complete controlling and monitoring of theheat pump including domestic hot water in one device

• Info page for quick request of themost important temperature and system states

• Integrated operating hours counter

• Thermal disinfection of domestic hot water (legionella mode)

• Probe protection function

• Emergency operation and frost protection function

• Configuration menu for all established hydraulic controls

• Guided commissioning assistance

• Browser-based configuration tool

• Continuous recording (data log) of the most important operating parameters for service and maintenance, as

well as operation analysis

Legend for abbreviations:

HP Heat pump BC Basic configuration

EW Electric utility Eco Protection functions activated

HC Heating circuit DHW Domestic hot water

CC Cooling circuit

Display

Alarm key – Flashes when alarm is activated. Press in order to access the alarm description and to

RESET thealarms.

Program key Start screen – Returns to thestart screen from any level.

(Key pressed for 3 seconds: Basic settings / Password entry)

Esc / Back – Cancel entries as well as back to the previous level.

Arrow Up – Scroll back as well as increase values.

Enter / Confirm – Selection of parameters, confirming entries as well as calling up levels previously se-

lected using thearrow keys.

Arrow Down – Scroll forwards as well as reduce values.

3 Basic information on operation

11Subject to technical changes © CTA 10/2016 www.cta.ch

3.1.1 Start screen

13

2

4

1: Navigation bar

The navigation bar can be used to access the main operating levels displayed using the arrow keys.

NOTE The levels „Information“ and „Settings“ are protected by password in some cases and can only

be accessed by qualified specialist personnel.

Start screen

Heating mode

Domestic hot water mode

Cooling mode

Information

Settings

2: Date & Time

The current settings can be adapted using the Program key (keep pressed for 3 seconds).

3: Status display

Outside temperature

Compressor status (ON/OFF/Blocked)

Outside temperature

- The current outside temperature, measured using theexternal sensor

Operating mode Heating / DHW / Cooling

- The current active operating mode for theheating, DHW and cooling mode are displayed respectively

Basic information on operation

12 Subject to technical changes © CTA 10/2016 www.cta.ch

Active priority control

NOTE Heating, DHW and cooling modes can never be carried out at thesame time. This symbol indi-

cates which mode is currently being operated.

- Heating symbol →Heating mode is active, water tap symbol →DHW mode is active or

cooling symbol →cooling mode is active

The current regulating temperature is displayed for this purpose

- Nominal: Current nominal temperature required from all active consumers

Compressor status

- The compressor symbol rotates →The heat pump is in operation

- The compressor symbol is stationary →The heat pump is not in operation

NOTE More displays for the current state are represented in the operating level „Information“.

4: External release

Draw wish / forced appears in case of increased heat demand. (Operation with SG Ready).

External blocked appears when, e.g., EW block is active. The compressor symbol is crossed-out .

3.1.2 General navigation

3

7

6

2

4

1

5

1: Operating level

2: Current screen / number of screens on this level

3: Number of parameter selected

4: Umbrella term of theparameter of this mask

5: Parameter selection

6: Parameter designation (parameter selected, - parameter

that can be selected)

7: Parameter value

3.1.3 Change parameters

1 2 3

1In order to change a parameter or the operating mode, this (these) must be selected on the respective mask

using the arrow keys . Press Enter to select the parameter. This is then highlighted black.

2When pressing the arrow keys you can now change the functions or values. When pressing the Enter

key , changes are confirmed and the parameter is no longer highlighted black.

3Several parameters such as, e.g., the time are changed in two steps. When pressing the Enter key , in

this case you access the hours and by pressing again, you access the minutes. Pressing Enter for a third time

completes the changes.

Basic information on operation

13Subject to technical changes © CTA 10/2016 www.cta.ch

3.2 Heating mode

In the chapter Heating you can change between the individual operating

modes, set the time program as well as carry out settings to the heating

curve. Using the ENTER key , you can access the parameters that can

be edited. These settings can be carried out for all available heating circuits

separately.

Heating circuits

No.* Screen display Description Default

value Unit

HK101 Operating mode HC1 Operating mode heating circuit 1 Frost protection

(Off) -

HK102/HK103 Hours/Minutes comfort phase 1 -

On HC1

Comfort mode heating circuit 1 -

Phase 1 On 06:00 h/min

HK104/HK105 Hours/Minutes comfort phase 1 -

Off HC1

Comfort mode heating circuit 1 -

Phase 1 Off 22:00 h/min

HK110 Comfort setpoint HC1 Comfort setpoint heating circuit 1 20 °C

HK111 Reduced setpoint HC1 Reducted setpoint heating circuit 1 19 °C

HK112 Frost protection HC1 Frost protection setpoint heating circuit 10 °C

HK113 Slope heating circuit HC1 Slope heating curve heating circuit 0.8 -

HK114 Offset heating curve HC1 Offset heating curve heating circuit 0 K

HK115 Heating limit HC1 Heating limit heating circuit 17 °C

* HK1xy = Heating circuit 1, HK2xy = Heating circuit 2, HK3xy = Heating circuit 3, ...

3.2.1 Operating mode Heating circuit 1

The operating mode and the time window of the comfort phase can be set in mask 1/6.

No. Screen display Description

HK101 Operating mode HC1 Operating mode heating circuit 1

You can select between the following operating modes:

Automatic mode (Auto):

Automatic mode regulates the room temperature according to the defined time window. Within the time window,

heating is carried out using the comfort setpoint (e.g., during the daytime) and outside the time window, using the

reduced setpoint (e.g., overnight).

Comfort or reduced mode:

These are continuous operating modes that keep the room temperature constant at the level selected. This is either

the comfort or reduced setpoint. No time program is active.

Off / Frost (Protective mode):

In Off / Frost mode, the heater is switched off. However, it remains protected against frost (frost protection tempera-

ture, factory setting +10°C), whereby the voltage supply must not be interrupted.

Basic information on operation

14 Subject to technical changes © CTA 10/2016 www.cta.ch

NOTE The Eco function is switched into automatic mode automatically when the device switches to

summer mode. (Operating mode Eco, Summer and Off / Frost (Protective mode) are identical.

Heating emergency mode:

In event of operational interruptions, theheat pump can be operated using an additional heat generator. The emergency

mode is regulated to thecurrent setpoint according to theheating curve set.

NOTE If emergency mode is demanded without valid electric heating element, an alarm message is

displayed and operation is interrupted.

WARNING!

Your heating installer must be informed when you are using the emergency mode.

NOTICE

No. Screen display Description

HK102/HK103 Hours/Minutes comfort phase 1 - On HC1 Comfort mode heating circuit 1 - Phase 1 On

HK104/HK105 Hours/Minutes comfort phase 1 - Off HC1 Comfort mode heating circuit 1 - Phase 1 Off

These parameters define thetime window for thecomfort phase in automatic mode (see graphic below).

3.2.2 Heating circuit setpoint

No. Screen display Description

HK110 Comfort setpoint heating circuit 1 Set the setpoint during the comfort phase

HK111 Reduced setpoint heating circuit 1 Set the setpoint outside the comfort phase (reduced value)

HK112 Frost protection setpoint heating

circuit Set the frost protection value when the heating mode is switched off

15

16

17

18

19

20

21

22

23

24

T [°C]

Time

Phase 1 ON

[HK002/HK003]

Comfort setpoint

[HK010]

Reduced setpoint

[HK011]

Phase 1 OFF

[HK004/HK005]

Phase 1 ON

[HK002/HK003]

Phase 1 OFF

[HK004/HK005]

06:0000:00 06:0022:00 22:00

Comfort setpoint

[HK010]

Basic information on operation

15Subject to technical changes © CTA 10/2016 www.cta.ch

3.2.3 Heating circuit heating curve

The setpoint for the heating flow is calculated using the current outside temperature and the set heating charac-

teristic curve. Now the flow temperature of the heating circuit should be regulated to this setpoint. The heating

characteristic curve can be adapted so that the heating output and therefore room temperature act according to

your personal requirements. This is carried out in mask 3/6.

No. Screen display Description

HK113 Slope heating curve HC1 Slope characteristic curve

The flow temperature changes more stronger with the slope, the lower the outside temperature is. A crucial factor

for the optimum value of the slope are the building shell and type of heating. The better the building shell and more

efficient the heating, the lower the slope can be set. The following graphic indicates this:

Flow temperature in°C

Outside temperature mixed in°C

15

20

25

30

35

40

45

50

55

60

65

-20 -15 -10 -5 0 5 10 15 20 25

Heizkurventemperatur in °C

Aussentemperatur gemischt in °C

VL (Steigung 1.1)

VL (Steigung 0.8)

VL (Steigung 0.5)

VL (Slope 1.1)

VL (Slope 0.8)

VL (Slope 0.5)

Example:

- Slope 0.5 (e.g. new building)

In the graphic, you can find three exemplary curves at 20°C outside temperature at the same point. The lower the

outside temperature drops, the flow temperature generated that has to be provided by the heat pump is higher de-

pending on the slope. The more efficient the heating system is, the lower the flow temperature can be, and therefo-

re also the slope. The room temperature, however, remains the same in all three cases.

Basic information on operation

16 Subject to technical changes © CTA 10/2016 www.cta.ch

No. Screen display Description

HK114 Shift heating curve HC1 Characteristic curve shift

If the room temperature is generally too warm or too cold, this can be corrected by a parallel shift.

Example:

If the comfort setpoint is set to 22°C and only 20°C is always measured in the room, this deviation can be correc-

ted by increasing the parameter shift (HK114) by 2K. Now the effective room temperature corresponds with the set

comfort setpoint.

Flow temperature in°C

Outside temperature mixed in°C

15

20

25

30

35

40

45

50

55

60

65

-20 -15 -10 -5 0 5 10 15 20 25

Heizkurventemperatur in °C

Aussentemperatur gemischt in °C

Komfortsollwert 22°C

Komfortsollwert 20°C

Comfort setpoint 22°C

Comfort setpoint 20°C

If the effective room temperature deviates even more from the set comfort setpoint the lower the outside tempera-

ture drops, the slope (HK113) can easily be adapted in the direction required.

Basic information on operation

17Subject to technical changes © CTA 10/2016 www.cta.ch

No. Screen display Description

HK115 Heating limit HC1 Heating limit

Where required, the heating limit can be edited via parameter HK115.

15

16

17

18

19

20

21

22

23

24

T [°C]

Time

Averaged outside

temperature (Ø 24h)

ON

OFF

Summer / Winter

Heating limit [HK015]

T Outside temperature in °C

ON Heating On => Winter

OFF Heating Off => Summer

Example (see graphic above):

From an outside temperature of 17°C, the heating limit has exceeded and the device runs in Eco mode and does

not heat. If the averaged otuside temperature drops below 17°C over the last 24 hours, the device switches back

to winter mode and starts to heat.

NOTE Wait at least 2 hours after each correction so that the room temperature can be adapted.

Summer / winter time switchover:

The function summer / winter time switchover switches the heating off if the averaged outside temperature exceeds

the set heating limit. The heating switches back on once the averaged outside temperature falls below the swit-

ching temperature.

In summer mode, the heating automatically switches to protective mode. The symbol ECO appears on the display.

The domestic hot water production is still guaranteed.

NOTE The summer / winter time switchover functions only in automatic mode. „Eco/Summer“ appears in

the display. The outside temperature is averaged to consider the dynamics of the building.

Basic information on operation

18 Subject to technical changes © CTA 10/2016 www.cta.ch

3.3 Domestic hot water mode

In the chapter Hot water you can switch on the domestic hot water

operating mode and define the time program. Using the ENTER key ,

you can access the parameters that can be edited.

When there is a demand for the domestic hot water charging, the heat pump is put into operation. This now heats

the domestic water to the desired setpoint. After reaching the setpoint, the heat pump switches off or, where requi-

red, to heating mode.

Domestic water

No. Screen display Description Default

value Unit

TW101 Operating mode DHW Operating mode domestic water Off -

TW102/TW103 Hours/Minutes comfort phase 1 -

On DHW

DHW charging nominal setpoint -

Phase 1 On 22:00 h/min

TW104/TW105 Hours/Minutes comfort phase 1 -

Off DHW

DHW charging nominal setpoint -

Phase 1 Off 04:00 h/min

TW110 Nominal setpoint DHW Nominal setpoint domestic water 51 °C

TW111 Reduced setpoint DHW Reduced setpoint domestic water 40 °C

TW112 DHW hysteresis Domestic water re-charge hysteresis 6 K

TW113 Legio-temp. Legionella temperature 60 °C

TW115 Activation Activation of the legionella program Off -

TW116 Per. Legionella program day Fridays -

TW117 Charge from Legionella program start time 02:00 h

3.3.1 Operating mode DHW

The operating mode and the time window of the comfort phase can be set in mask 1/4.

No. Screen display Description

TW101 Operating mode DHW Operating mode domestic water

You can choose between the following operating modes via parameter TW101:

Domestic water mode ON:

The domestic water mode heats according to a defined time window. Heating is carried out to the nominal setpoint

within the time window (e.g., overnight). The heating outside the time window is only carried out to the reduced

setpoint.

Domestic water mode OFF:

No domestic water preparation.

Domestic water Push (Domestic water – quick charging):

If the function is selected, an immediate heating of the domestic hot water is carried out to the configured legionella

temperature. After reaching the desired temperature, the operating mode is automatically reset to the last setting.

Basic information on operation

19Subject to technical changes © CTA 10/2016 www.cta.ch

NOTE A periodic heating to legionella temperature can be activated using the legionella program „3.3.3

Legionella program“ on page 20

No. Screen display Description

TW102/103 Hours/Minutes comfort phase 1 -

On DHW Comfort phase DHW On

TW104/105 Hours/Minutes comfort phase 1 - Off

DHW Comfort phase DHW Off

These parameters define the time window for the nominal setpoint in Domestic water mode ON.

Operating mode temporarily OFF

With planned longer absence, the DHW mode can be switched off temporarily. Restoring the DHW mode is carried

out using the set date.

1 2

DHW emergency mode:

In event of operational interruptions, the heat pump can be operated using an additional heat generator. The emer-

gency mode is regulated to the current setpoint according to the DHW setpoint set.

NOTE If emergency mode is demanded without valid electric heating element, an alarm message is

displayed and operation is interrupted.

WARNING!

Your heating installer must be informed when you are using theemergency mode.

NOTICE

Basic information on operation

20 Subject to technical changes © CTA 10/2016 www.cta.ch

3.3.2 Setpoints

The domestic water can be conducted according to the nominal or reduced setpoint. These can be edited via

mask 2/4 and the parameters TW110 und TW111. The hysteresis (TW112) is the deviation that the domestic hot

water may have from the setpoint before the heat pump starts heating.

No. Screen display Description

TW110 Nominal setpoint DHW Nominal setpoint domestic water

TW111 Reduced setpoint DHW Reduced setpoint domestic water

TW112 DHW hysteresis Domestic water re-charge hysteresis

Example:

The device operates in reduced mode, 47°C is configured as reduced set-

point. Hot water is consumed, the temperature drops in the storage tank.

The hysteresis is set with 5K. The device therefore starts with the hot water

production as soon as the temperature in the storage tank falls below 42°C

(47°C – 5K = 42°C).

40

45

50

55

65

T [°C]

Time

Phase 1 ON

[TW002/TW003]

Nominal setpoint

[TW010]

Reduced setpoint

[TW011]

Phase 1 OFF

[TW004/TW005]

Phase 1 ON

[TW002/TW003]

20:00 20:0005:00

3.3.3 Legionella program

No. Screen display Description

TW113 Legio-temp. Legionella temperature

TW115 Activation Activation of the legionella program

TW116 Per. Legionella program day

TW117 Charge from Legionella program start time

In the mask TWW 3/4, the legionella mode can be switched on or off as well as defined. If the activation is set to

ON (TW115), the heat pump heats the storage tank to the desired legionella temperature (TWW113) on the defined

week day or daily (TW116) at the selected time (TW117).

NOTE „Legio/act.“ appears in the display when legionella charging is active.

Basic information on operation

Table of contents

Other CTA Controllers manuals