10

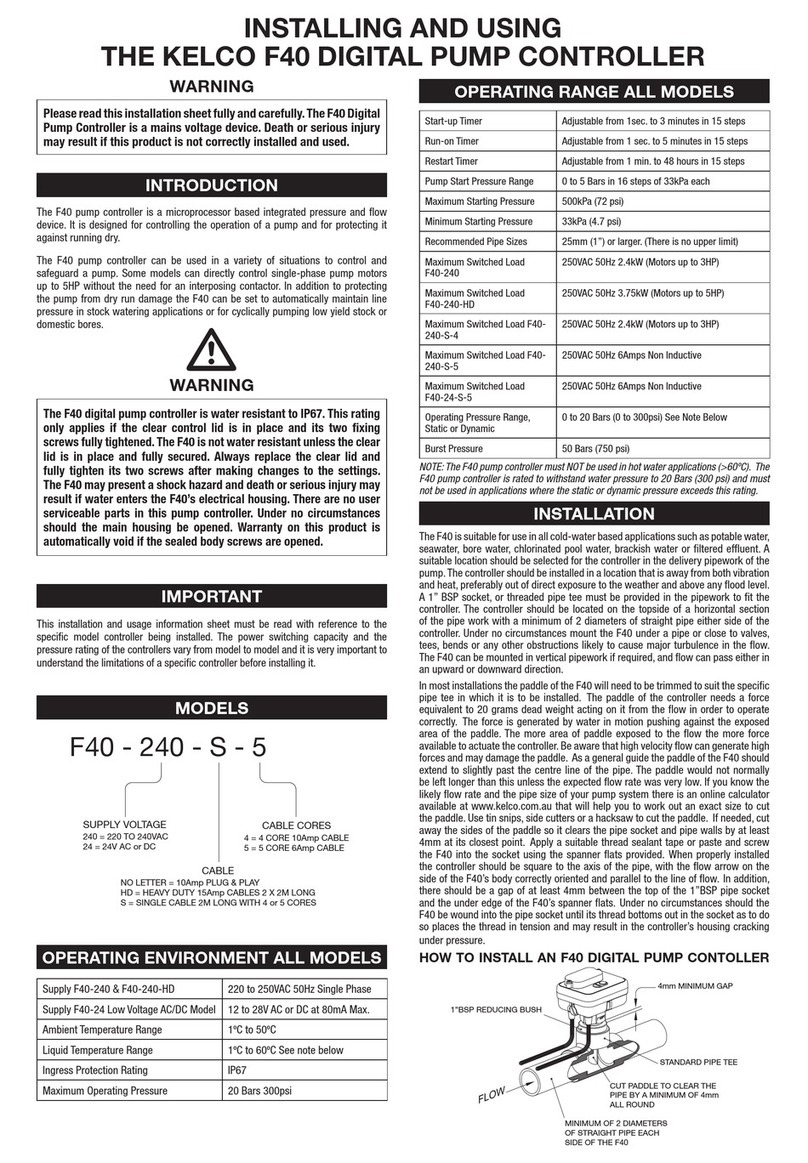

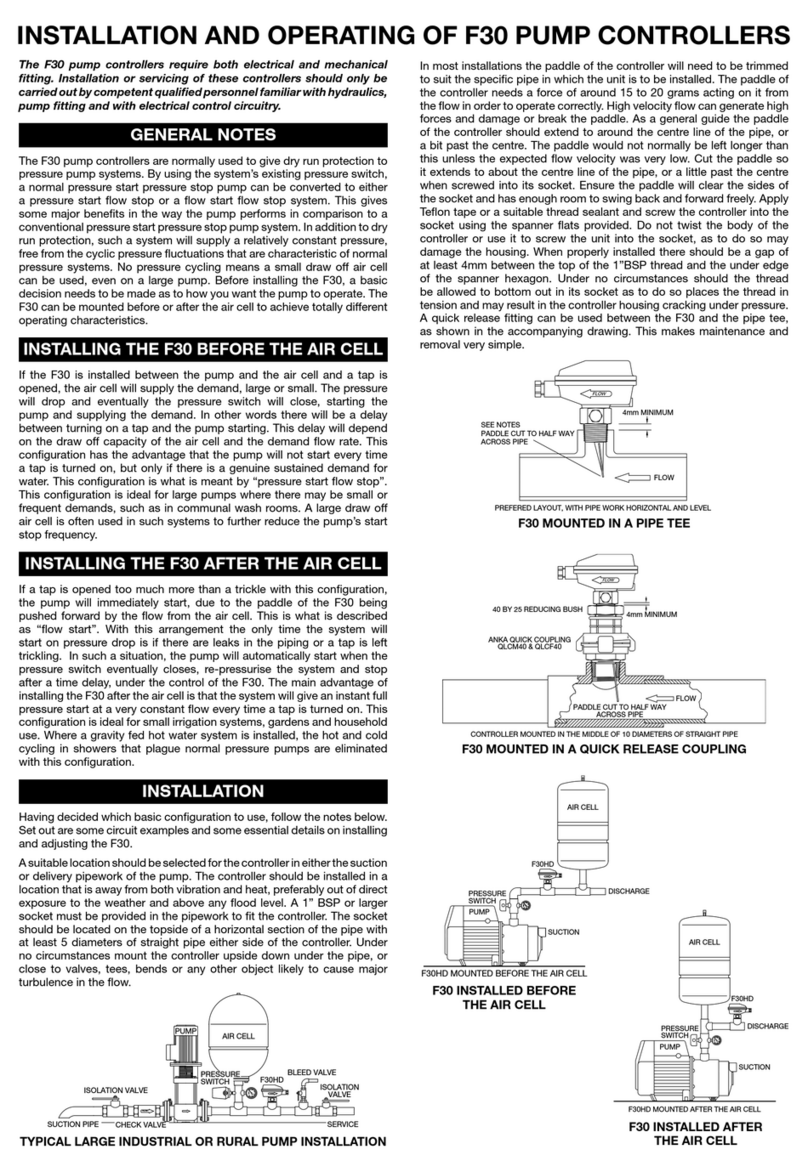

TRIMMING THE PADDLE

The paddle of the F60 can be cut down to suit the specific pipe size and

intended application. Cut the paddle using a hacksaw or tin snips so it

clears the sides of the pipe socket and protrudes approximately half to two

thirds of the way across the pipe when the controller is screwed into the

pipework. If the flow rate will only ever be fairly low, the paddle should be

cut longer, perhaps until it only clears the bottom of the pipe by 3 to 5mm.

If you are unsure as to what length the paddle should be, a paddle trimming

calculator is available at.

http://www.kelco.com.au/paddle-trimming-calculator-2

If you know what the expected flow rate is the calculator allows you to enter

your pipe diameter and paddle dimensions. It will then determine if the

selected paddle dimensions are adequate for the application. Spare

paddles to suit the F60 are available from Kelco or from your distributor.

To fit the paddle assembly into the pipework, apply Teflon tape or thread

sealing compound to the thread and use a suitable spanner and the

spanner flats provided on the paddle assembly (directly above the process

connection thread). Under no circumstances should the electrical housing

be twisted or used to screw the paddle assembly into the pipework, or to

align the controller with the axis of the pipework. To do so will irreparably

damage the controller and void its warranty. When correctly installed there

should be a minimum 4mm gap between the top of the pipe socket and the

top of the thread on the F60. Never apply water pressure to the F60 unless

the electrical head is fitted and the M4 locking screw is in place and fully

tightened. The F60 can be installed in either vertical or horizontal pipe.

When installed in vertical pipework flow should preferably be in an upward

direction past the controller’s paddle. The F60 has a 1” BSP process

connection. A matching female threaded socket, pipe saddle or pipe tee

must be provided to fit the controller into pipework.

ATTACHING THE ELECTRICAL HOUSING

Once the paddle assembly has been installed, fit the electrical housing

onto the spigot on top of the paddle assembly. Take care that the sealing

O-ring is on the top stem of the paddle assembly is in location and in good