Crane Source Space Vector SFV1000 Assembly instructions

3

SFV1000

Table Of Contents

Introduction................................................................................................................ 4

Section 1: Installation

Step 1: Inspection of Drive ..................................................................................6-13

Step 2: Mounting the Drive................................................................................14-17

Step 3: Wiring the Drive.....................................................................................18-29

Section 2: Start Up Programming

Step 1: Keypad Layout.......................................................................................29-30

Step 2: Keypad Operation

Definitions .................................................................................................. 31

Moving Through Each Group Level............................................................ 32

View a Specific Function [Code No.] Using Jump Code Location ............. 33

Viewing all Function [Code No’s] Within a Group Level............................. 34

Function Code List ................................................................................35-39

Step 3: Auto Tuning............................................................................................40-42

Step 4: Initial Setup Programming

Programming the Drive for a Specific Application ................................43-45

Programming the Speed Selection .......................................................46-49

Drive Operation Checks .............................................................................50

Section 3: Programming

Passwords and Group Access Levels ..................................................................... 52

Entering a Password .................................................................................. 53

Back Door................................................................................................... 54

Changing a Password ................................................................................ 55

Programming Function Data ...................................................................................56

Section 4: Trouble Shooting

FaultTrip Descriptions and Reasons for Faults....................................................... 58

Monitoring Fault Trips .........................................................................................59-60

Trouble Shooting Flowcharts..............................................................................61-66

Trouble Shooting Procedures .............................................................................67-72

Pushbutton Pendant Test......................................................................................... 73

Multi-function and Analog Output Test .................................................................... 74

Section 5: Features ...............................................................................................75-85

Section 6: Detail In/Out and Function Code Descriptions

Multi-function Contact Inputs..............................................................................86-89

Multi-function Contact Outputs................................................................................ 90

Function Code Description ...............................................................................91-104

4

SpaceVector™ Variable Frequency Drives

Congratulations on the purchase of a SpaceVector™ SFV1000 Series drive.This is the most

advanced drive on the market today specifically designed and programmed for the overhead

material handling industry by the leader in the industry, Columbus McKinnon Corporation.

SpaceVector™ drives have many advantages and features to meet the very specific and

demanding needs of the crane and hoist industry. Features such as:

•Most efficient energy utilization of any drive on the market resulting in less motor heat.

•Cooler running motors last longer saving on downtime and maintenance costs.

•Efficient utilization produces more torque resulting in better load control.

•Reduced motor harmonics improving motor performance and lengthening life.

•Easy Macro Quick Set Programming for faster start-up and servicing.

•Plain English programming and service manual saves time.

Before proceeding any further, please read the following important information regarding the

drive and its proper handling and use:

•Please read this manual completely before working with the drive.

••

••

•Thedrive operates onand containshighvoltage that cancauseelectric shockresulting

in personal injury or loss of life. Handle the drive with the same care and caution as

all other high voltage electrical components.

••

••

•Be sure to disconnect all AC input power to the drive before servicing. Lock and tag

the main switch in the de-energized position per ANSI Z 244.1

••

••

•Wait at least 3 minutes after disconnecting the AC input power to the drive. If the bus

capacitor discharge circuit fails, high voltage can remain in the drive for a period of

time after the AC power is disconnected.

••

••

•Do not perform high voltage tests such as Megger testing.

••

••

•Only qualified personnel should perform service.

••

••

•Insure unit is properly grounded.

••

••

•Disconnect drive before performing any welding on the bridge crane structure. Do

not weld the hook to the hook or to a load suspended from the hook.

• Never turn off the power of the drive unless load is on the ground.

Onthe followingpages arespecificationandselectiontablesfor thedrives anddynamicbraking

resistors.Please check to insure you have the proper equipment for your application.

IMPORTANT! PLEASE READ!

WARNING

5

Section 1: Installation

Step 1: Inspection of Drive

Step 2: Mounting the Drive

Step 3: Wiring the Drive

6

Step 1: Inspection of Drive

•Inspect the drive for any physical damage that may have occurred during its shipment. If

any parts of the drive are missing or damaged, contact your SpaceVector™distributor

immediately.

•Verify the nameplate of the SFV1000 drive.Verify that the drive part number matches

your order and packing slip.

•Verify that the Dynamic Braking Resistor part number matches your order and packing

slip.

•If there are questions, reference Tables 1.1, 1.2, 1.3, 1.4 and 1.5 for Drive and Resistor

specifications.

WORKING IN OR NEAR EXPOSED ENERGIZED

ELECTRICAL EQUIPMENT PRESENTS THE DANGER

OF ELECTRIC SHOCK.

TO AVOID INJURY:

•Disconnect and lockout power to the drive per

ANSI Z 244.1

•Wait 3 minutes after disconnecting power for

capacitor to discharge before entering drive.

WARNING

7

Item Specification

Control

Topology SpaceVector PWM using IGBT

Controller Field oriented control, Speed controller with minor current

controller

Speed control accuracy –0.2% (analog), –0.01% (digital) of maximum speed

Speed setting resolution –0.005% of maximum speed

Cutoff frequency of ASR 50 Hz

Range of torque control 1:50

Torque control accuracy –5%

Acceleration/Deceleration 0 ~ 3600 sec, 2 sets of acceleration and deceleration time

available, linear / s curve

Braking Dynamic braking with external resistor (150% of rated torque)

2.2 ~ 7.5 kW : DB circuit is included

Protection Overcurrent, Overvoltage, Low voltage, Inverter overheat,

Inverter NTC failure, Motor overheat, Motor NTC failure, Over

speed, External trip, Fuse open, Ground Fault Protection

Input

Speed setting Terminal V1, V2 (0 ~ –10V, polarity available), Terminal /

(4~20mA)

Analog input 2 Terminal V1, V2 (0 ~ –10V)is defined by user among 7

functions (*1)

Contact inputs FX (forward/up run), RX (reverse/down run), BX (emergency

stop), RST (reset) 7 multi-function inputs (P1~P7) are defined

by user among 17 functions (*2)

Output

Analog output 1 - Analog output 2 Two (2) analog outputs are defined by user among 13 data

selections (*3)

Fault relay A (normal open), B (normal close) C (common)

Auxiliary relay 1, 2 [A1, 1B], [2A, 2B] (normal open) are defined by user among

11 functions (*4)

Open collector 1, 2, 3 OC1, OC2, OC3 are defined by user among 11 functions (*4)

Operating

Condition

Altitude Less than 1000m without derating

Temperature and humidity -10 C ~ 40 C, 90% relative humidity, noncondensing

Cooling Forced air cooling

Class of enclosure [2.2 ~ 7.5kW] IP52, [11 ~ 22kW] IP20

Table 1.1 - SFV1000 Drive Common Specifications

*1 Speed reference value,Torque reference value, Flux reference value,Torque bias value,Torque

limit value, Outer PI Controller reference Input, Outer PI Controller feedback.

*2 Multi-speed select , Multi-accel./decel. time select, Soft start cancel, ASR PI gain select, ASR

P/PI select, Flux reference select, Pre-excitation External trip input (Normally Closed), Speed/

Torque control select, Torque limit ON, Torque bias ON, Forward-run prohibit, Reverse-run

prohibit, 3-Wire Operation, External trip input (Normally Opened).

8

*3 Motor speed(no polarity), Motorspeed (polarity available),Speed reference 1,Speed reference

2,Torquereference 1,Torque reference 2,Torquereference 2(polarity available),Torquecurrent,

Flux reference Magnetizing current, Inverter output current, Inverter output voltage, Motor

temperature, DC link voltage.

*4 Zero speed detection, Speed detection (polarity available), Speed detection (polarity ignored),

Speed arrival, Speed deviation, Torque detection, Torque limiting, Motor overheat warning,

Inverter overheat warning, Low voltage warning, Inverter running.

Table 1.2 - SFV1000 Drive Specifications According to the Capacity for 230Volts

SpaceVector™Drive Specifications

(230 V)

Drive 446485 -30 -31 -32 -33 -34 -35 -36 -37 -38 -39

Output

Ratings

Capacity [kVA] 4.2 6.1 9.1 12.2 17.5 24.3 30.5 36.2 46 55

Continuous rated [FLA] 11 16 24 32 46 59 74 87 122 146

RefHP 3 57.510152025304050

Input

Ratings

Input voltage 200 ~ 230V

Input voltage + 10% ~ -15% (Below 200V, output power is too low)

Input frequency 60 Hz (–5%)

Control Overload Capacity 150%, 1 minute

9

Table 1.3 - SFV1000 Drive Specifications According to the Capacity for 460Volts

SpaceVector™Drive Specifications

(460 V)

Drive 446485 -50 -51 -52 -53 -54 -55 -56 -57 -58 -59 -60 -61 -62 -63 -64

Output

Ratings

Continuous rated

(FLA) 5.5 8 12 16 24 30 39 45 61 75 91 110 152 183 223

RefHP 3 57.5101520253040506075100125150

Input

Ratings

Input voltage 400 ~ 460V

Input voltage + 10% ~ -15% (Below 400V, output power is too low)

Input frequency 60 Hz (–5%)

Control Overload Capacity 150%, 1 minute

10

Table 1.4 - Braking Resistor Guide

Input

Voltage Applied

Motor Inverter

Identification

Recommended Braking Resistor - for Hoists without

Mechanical Load Brake

Watts Ohms Resistor

Part Number

230V

2.2kW (3 hp) 446485-30 1200 60 446485-A8

3.7kW (5 hp) 446485-31 2400 30 446485-B3

5.5kW (7.5 hp) 446485-32 3600 20 446485-B6

7.5kW (10 hp) 446485-33 4800 16 446485-C0

11kW (15 hp) 446485-34 7200 10 446485-C3

15kW (20 hp) 446485-35

18.5kW (25 hp) 446485-36 10800 7 446485-C4

22kW (30 hp) 446485-37

30kW (40 hp) 446485-38

37kW (50 hp) 446485-39

460V

2.2kW (3 hp) 446485-50 1600 200 446485-B0

3.7kW (5 hp) 446485-51 2400 120 446485-B2

5.5kW (7.5 hp) 446485-52 4000 80 446485-B8

7.5kW (10 hp) 446485-53 4800 60 446485-B9

11kW (15 hp) 446485-54 7200 40 446485-C1

15kW (20 hp) 446485-55 7200 30 446485-C2

18.5kW (25 hp) 446485-56 14400 20 446485-C6

22kW (30 hp) 446485-57

30kW (40 hp) 446485-58 14400 16 446485-C7

37kW (50 hp) 446485-59 14400 13 446485-C8

45kW (60 hp) 446485-60 20000 7.7

56kW (75 hp) 446485-61 24000 6.3

75kW (100 hp) 446485-62 30000 5.0

94kW (125 hp) 446485-63 45000 5.35

112kW (150 hp) 446485-64 55000 4.38

11

Terminal Connection Terminal State

B1, B2 Inverter main power terminal circuit P, R

P7, CM Connect the Inverter control terminal P7, CM and select the

multi-function input of P7 to Normally Closed External trip (10)

to detect the overheating of the resistor unit

Normally ON until the resistor is

overheated, then P7 input

becomes open

Table 1.5 - Resistor Unit Specifictions

12

Step 2: Mounting the Drive

Environmental Conditions

•Verify the ambient condition of the drive mounting location.The ambient temperature range

should be 14 to 104°F (-10 to 40°C).

•The relative humidity should be less than 90% (non-condensing), below the altitude of 3280 ft.or

1000m.

•Do not mount the drive in direct sunlight.

•The drive should be isolated from excessive vibration.

•Thedriveshould beprotected frommoisture,dust, metallicparticles, corrosivegases andliquids.

Mounting

•TheSFV1000mustbemounted verticallywithsufficient space(horizontallyandvertically) between

adjacent equipment to permit proper heat dissipation. See Figure 1 below. See pages 13 - for

actual drive dimensions and Table 1.6 for drive enclosure size.

Fig. 1 - Recommended Clearances for Drive Mounting

A: over 6.0'' (15cm)

B: over 2.0'' (5cm)

A

A

B

B

13

Size 1 SFV1000 Drive Dimensions

Table 1.6 - SFV1000 Drive Enclosure Sizes

Drive Part Number Size NEMA Rating

446485-30 1

NEMA 1

446485-31

446485-32

2

446485-33

446485-50

446485-51

446485-52

446485-53

446485-34

3

446485-35

446485-54

446485-55

446485-36

4

446485-37

446485-56

446485-57

446485-58 5

446485-38 6

446485-39

446485-59 7446485-60

446485-61

446485-62 8

14

Size 2 SFV1000 Drive Dimensions

Size 3 SFV1000 Drive Dimensions

15

Size 4 SFV1000 Drive Dimensions

Size 5 SFV1000 Drive Dimensions - 40hp @ 460V

21.88’’ (556mm)

.47’’ (12mm)

2- .39’’dia (10mm)

21.06’’ (535mm)

22.83’’ (580mm)

4.72’’ (120mm)

8.27’’ (210mm)

11.02’’ (280mm)

9.05’’ (230mm)

11.81’’ (300mm)

10.63’’ (270mm)

MODE

REV

ENTERPROG

FWD

STOP

RESET

A1;10.63"

(270MM)

A1;10.63"

(270MM)

A1;13.78"

(350MM)

16

Size 6 SFV1000 Drive Dimensions - 40 & 50hp @ 230V

Size 7 SFV1000 Drive Dimensions - 50, 60 & 75hp @ 460V

10.83" (275mm)

14.17" (360mm)

14.76" (375mm)

PROG

RESET

MODE

REV

ENTER

STOP

FWD

24.21" (615mm)

23.37" (593.5mm)

9.07" (230.5mm)

10.45" (265.5mm)

10.93" (277.5mm)

10.83" (275mm)

17.72"

(450mm)

14.06"

(357mm)

MODE

REV

ENTERPROG

FWD

STOP

RESET

14.06"

(357mm)

17

Size 8 SFV1000 Drive Dimensions - 100hp @ 460V

Size 9 SFV1000 Drive Dimensions - 125 & 150hp @ 460V

14.17" (360mm)

14.76" (375mm)

10.83" (275mm)

FWD

ENTER

STOP

REV

MODE PROG

RESET

29.86" (758.5mm)

30.71" (780mm)

10.83" (275mm)

11.84" (300.7mm)

11.09" (281.7mm)

9.07" (230.5mm)

19.97" (507mm)

16.94" (430mm)

20.87" (530mm)

11.17" (283.5mm)

12.60" (320mm)

9.08" (230.5mm)

29.93" (760.0mm)

30.72" (780mm)

18

P4

P3

P2

P1

RX

FX

P5 G

30B

30C

1A

BB 2A

1B

2B

BB OH

91 C

B1

B2 B

H91(HOT) 92(COLD)

HCFU

PFU

PFU

G

F

PL2

PL1

PRIMARY

SECONDARY HCPT

(X2)(X1)

112345678910

TO STARVERT - iV DRIVE

RST

EF

G

WVU

B1

B2

DBR

DB1

DB2

STARVERT- iV

HT1 HT2 HT3

T2

T1 T3 HOIST MOTOR

ENCODER

L1 L2 L3

HFU

HL3HL2HL1

SH

B-

B+

A-

A+

5G

P5 (+5)

(0V)

(B+)

(B- )

(A+)

(A- )

S10

54321 12345

UP DOWN

DENOTES CLOSED CONTACT

HOIST MOTOR

BRAKE COIL (DC)

MAI N BOARD - i V

OPT120VAC - i V

TO ENCODER

32

LL

1

L

B

BRAKE

COIL

SA

115

B

BB

SA

BB

AX230B 30C AX1

NC NO

N

(X 2 )

MAIN BOARD

Contactor Brake Contactor Coil

(X 1 )

Backup Brake

Step 3: Wiring the Drive

Remove Cover From Drive

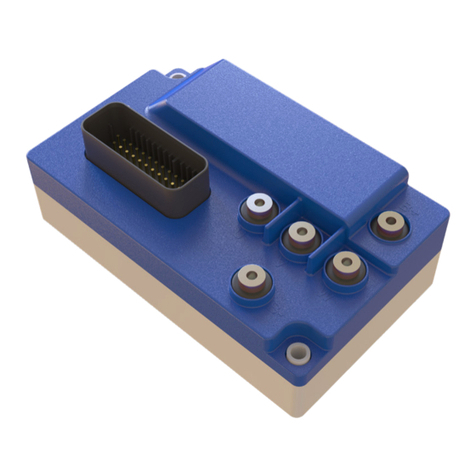

Figure 2 below is a reference for the basic Input / Output Terminals of a SFV1000 drive.

Fig. 2 –Basic wiring diagram for the SFV1000 drive.

2A

B

C

1A

B C 1A 1B

SFV1000

To SFV1000 Drive

120VAC Interface SFV1000 Main Board

WARNING DEVICE

19

SFV1000

Drive Class Drive Rated

Amp. Input

AWG Output

AWG Ground

AWG DB Resistor

AWG Control

AWG

230V

Class

11.0 12 12 12 12

16

16.0 1024.0 10 10 10

32.0

46.0 6686

59.0

74.0 4464

87.0

460V

Class

6.0

12 12 12 12

8.0

12.0

16.0

10

24.0 10 10 10

30.0

39.0 88 8

45.0

61.0 66 6

75.0

91

110

152

183

223

Check For CorrectWire Gauges

Insure the correct wire gauges for the input and output power leads are being used before wiring

the drive. Use Table 1.7 for reference.

Table 1.7 –Wire Gauge Reference Table.

20

Fuse and Circuit Breaker Selection

Reference Table 1.8 to properly apply fuses and circuit breakers to the drive.

Table 1.8 –Fuse and Circuit Breaker Selection

SFV1000

Drive Voltage Ref. HP SVF1000

Part Number Fuse Rating

Class (J) Molded Case

Circuit Breaker

230V

3 446485-30 20A 25A

5 446485-31 25A 30A

7.5 446485-32 35A 50A

10 446485-33 40A 60A

15 446485-34 50A 75A

20 446485-35 80A 100A

25 446485-36 125A

30 446485-37 100A 150A

460V

3 446485-50 10A 15A

5 446485-51 15A 20A

7.5 446485-52 20A 25A

10 446485-53 25A 30A

15 446485-54 35A 40A

20 446485-55 40A 50A

25 446485-56 50A 60A

30 446485-57 65A 75A

40 446485-58 70A 125A

50 446485-59 80A

60

75

100

125

150

21

R S T E U V W E B1 B2

WiringThe Power Leads

Use Figure 3 as shown below to assist in wiring the power leads to the drive.

Fig. 3 –Input / Output Power and Dynamic Braking Resistor Wiring Diagram.

Arrangement of PowerTerminal Strip

L1 L2 L3 Earth T1 T2 T3 DBR DBR

3 Phase Input Power

230 VAC or 460 VAC 3 Phase Output to

Motor Dynamic Braking

Resistor Unit

Terminal Symbol Description

Main Power

Terminal

R, S, T 3 Phase Input Power Terminals

U, V, W 3 Phase Output Terminals

B1, B2 External Dynamic Braking Resistor Terminals

EGround Terminals

Earth

Note: Slotted tongue terminals are recommended for connections shown in Figure 7.

This manual suits for next models

1

Table of contents

Other Crane Source Controllers manuals