CTC Communications FDM Series User manual

1

CTC Desktop 3D Printer Manual

FDM Series

Company Name: CTC Co., Ltd.

Website:www.ctcprint.com

2

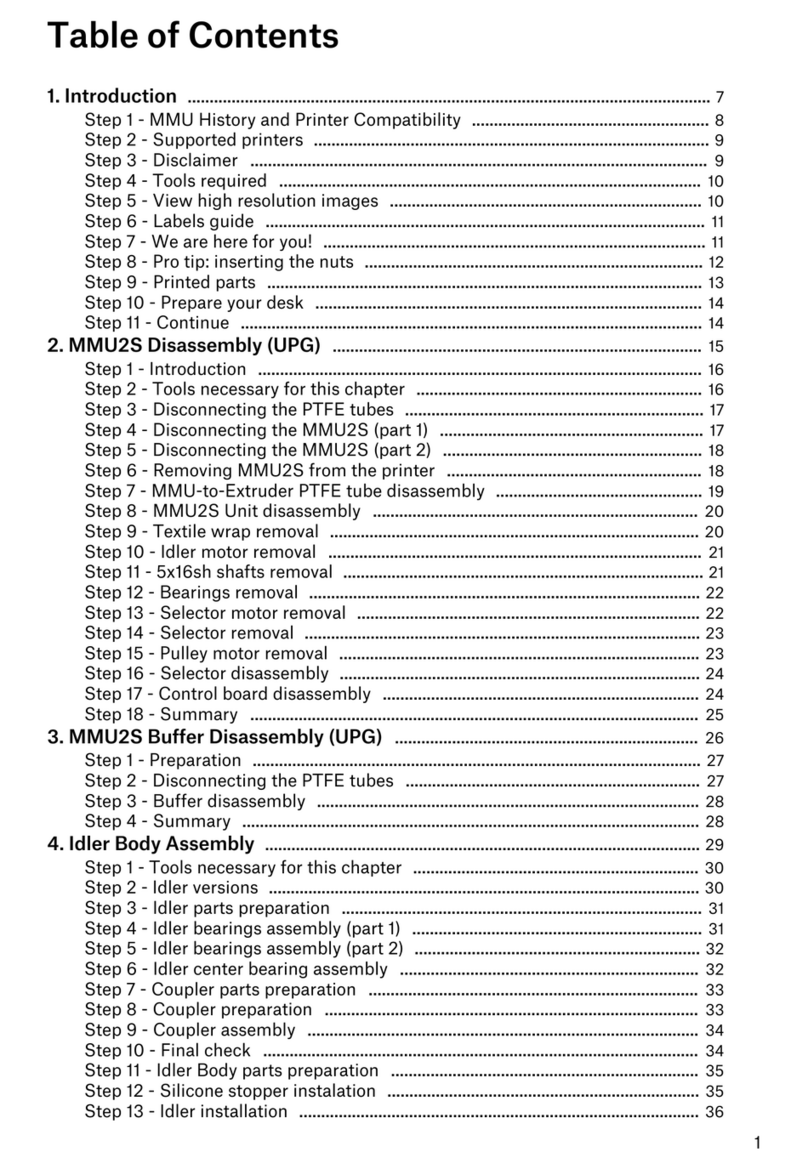

Catalogue

1.Instructions..................................................................................................................................... 3

1.1 Introduction ................................................................................................................................. 3

1.2 Precautions .................................................................................................................................. 3

1.2.1 Safety Precautions ..................................................................................................................... 3

1.2.2 Contact ..................................................................................................................................... 3

1.3 Accessories List ........................................................................................................................... 3

2. Product Category............................................................................................................................ 4

2.1 Product Overview......................................................................................................................... 4

2.2 Appearance ................................................................................................................................. 4

2.3 Product Specifications .................................................................................................................. 5

2.3.1 Parameters................................................................................................................................ 5

2.3.2 recommended environment ....................................................................................................... 6

3.Operating Instructions ..................................................................................................................... 6

3.1 Unpacking and preparation before printing...................................................................................... 6

3.1 Computer preparations.................................................................................................................. 9

3.1.1 Install the Replicatorg driver software..................................................................................... 9

3.2.2 Software Description ................................................................................................................ 12

3.2.3 Install the driver software of Makerware ................................................................................... 18

3.3 The instructions of the key of LCD screen ..................................................................................... 28

4. Take out model ............................................................................................................................ 33

5.2tighten the belt............................................................................................................................ 34

5.3 maintenance of the optical axis and the screw rod........................................................................ 35

6 .Troubleshooting ........................................................................................................................... 36

7. Common Problems and Solutions ................................................................................................... 36

8. Warranty and License Agreement affirms ....................................................................................... 37

3

1.Instructions

1.1 Introduction

This Instructions consist of the product overview, operating instructions, printing test

model, maintenance and troubleshooting. Please read it carefully and operate the 3d printer

according to the brochure.

1.2 Precautions

Since different area have different voltage, please make sure how much is your

voltage (110v and 230v generally)

After using this product over a period of time ,it is necessary to maintain it .Proper

maintenance can often extend the life of the printer

1.2.1 Safety Precautions

It is not suggested that using other brands of printing-supplies . To get the best results

of 3D printing, please use the supplies of our company . The maintenance and repair caused

by using other supplies ,are not included in the Company's warranty

Touch is prohibited when the printer is working or the moment after finishing the

printing since the temperature is quite high in the model, the head ,the printing platform or

the other parts of the printer .

1.2.2 Contact

If you need after-sales service, you can directly add our business group, which

number is 102304634. SD Card User's Guide: the information on using and troubleshooting

the 3D printer is available in our enclosed instructions. Online technical support is also

provided by adding our group(102304634).

You can also add Sina microblog of our company so as to have a better understand of

the update of new technology as well as the upgrade of software in our company. Besides ,

random rewards would be got by adding our microblog .The luckiest one would get one

Tablet PC. Enter into the Sina microblog then search 西通 3D 打印未来.The more attention

and forwarding, the more opportunities you will get the prize .

1.3 Accessories List

No

Material name

Quantity

Unit

1

3D printer

1

set

2

Power line

1

stick

3

USB Data Cable

1

stick

4

4

Kit

1

set

5

SD card

1

single

6

Printing Supplies

1

reel

7

Hanging material

column

2

strip

2. Product Category

2.1 Product Overview

CTC 3D printer is a rapid prototyping device based on the fuse deposition

manufacturing process (FDM), which prints by connecting to the computer via USB cable

online or SD card offline and just an ordinary computer can finish printing. A STL 3D file

format can complete a variety of print job of complex three-dimensional solid model. The

device is easy to operate, so even if you have never used 3D printer, CTC 3D printer is also

a good choice for your to finish types of printing of 3D models.

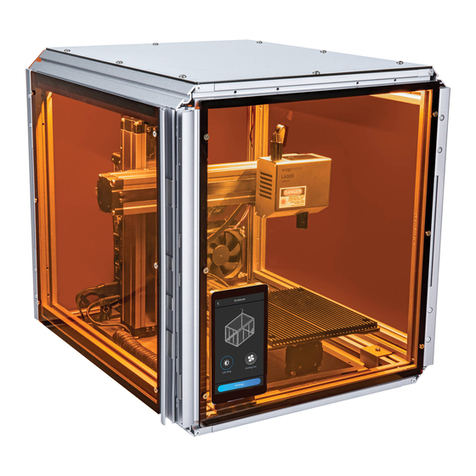

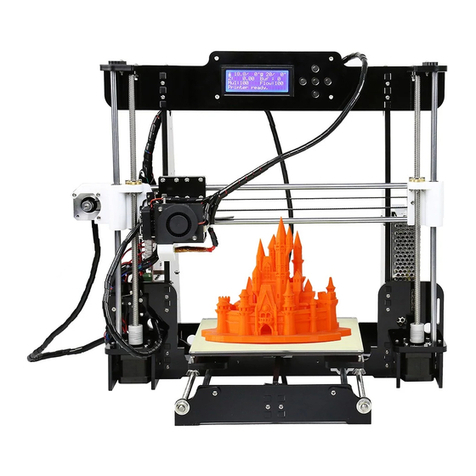

2.2 Appearance

Third generation

5

First generation

Second generation

2.3 Product Specifications

2.3.1 Parameters

The total volume of printers :320*467*381mm

Package Size:565*430*535mm

Weight (with packaging) :13.5KG

Build Size :225*145*150mm

Power:210V

Build platform’s temperature: about 110 (proper winter heating and summer cooling)

Extrusion nozzle flow: about 24cc / h

6

Supported operating systems: Windows XP Windows7 / 8 (32 bits / 64)

Software: ReplicatorG or CTC Chinese version (compatible on MakerWare software)

Print materials: ABS, PLA

Material properties: 3D printing special ABS and PLA (exclusive qualities recipe)

Layer accuracy: 0.1mm-0.5mm

Positioning accuracy: XY axis 0.011mm

Filament diameter: Z axis 0.0025mm

Nozzle diameter: 0.4mm

Motion axis speed: 30mm/s_100mm/s

Recommended head movement speed : 35-40 mm / s

Input file types: stl, gcode

2.3.2 recommended environment

Operating environment: clean install in a well ventilated area. Temperature: 15 ° C to 35 ° C.

Humidity: 20-80% (non-condensing).

Storage environment: Temperature: 0 ° C to 40 ° C Humidity: 10-80% (non-condensing).

The presence :non-corrosive gases and cleaning place

3.Operating Instructions

3.1 Unpacking and preparation before printing

(1) Check whether there are some scratches and other defects on the appearance of 3D

printers outside the box bumps

7

Check whether there are some deformations caused by squeezing or rupture in the corners of

the box.

(2) Open the box and remove the printer then cut the nozzle and fix tie (tied to the front left

side of the Z-axis X-axis Y-axis.

Cut fixed print head straps with water-nose pliers.

(3) Open the foam of the surface of print head (Note: Try not to use the face of knife so as to

prevent the print head was hanged up ) Mount the print head to a bracket on the X-axis,

installation direction as shown ,then tighten the two screws.

(Picture1) (Picture2)

(4)Take out the hanging tube and then install it in the hole of the hanging tube at the back of

the printer, load the printing supplies into the hanging tube, then pull printing supplies, insert

one of a printing supplies section into the round role of the print head (Note: insert in the

left when use the left print head while insert in the right then use the right one )

8

(5)Check whether the Limit switch cable of the printer losing or falling off the surface.

(Z-axis limit) (Y-axis limit) (X-axis limit)

(6) Check whether the voltage match to the printer’s (110 or 220, judged by the power

at the bottom of the printer)

(7) Take out the SD card , read printer driver inside the SD card, then install the driver.

(8) Turn on the printer and manipulate the control panel so that the Z axis went to the top of

the printer, check whether the distance of printer nozzle and print platform meets the criteria

(optimal distance test method: Put a piece of A4 paper in printing platform surface, control

panel so that it went to the top of the Z-axis, then pull A4 paper. The printing paper can be

pulled out with a little effort so that the paper will not be scratched) Note: the blue paper of

the surface of the platform cannot be torn, otherwise it will affect the printing quality.

(9)Prepare for files of STL format ,open the file through the software already installed in

the printer .Then adjust the parameters and you can start printing

9

3.1 Computer preparations

3.1.1 Install the Replicatorg driver software

(1)take out SD card and read printer driver inside it . Looking for the 3dsetup folder

(2)Open the 3dsetup folder and then search for the file of software

(3) open the file of software by Right-clicking then enter into the software installation

manager

(4)Click Replicatorg software installation (both English and Chinese is available to

install depending on your preferences )

10

(5) Click “ automatic installation” in Replicatorg software .When a icon be shown

then click the “Next ”button.

(6)Another icon will be shown after click the “Next” button ,then click the “install”

button.

(7) A window will jump out after the install button, please wait a minute at this time.

11

(8) After clicking the Install button ,there is a dialog box, then click the next button.

(9) After clicking, the computer will appear five Prompts . Please click "Install this

driver software anyway."

(10)After Clicking "Install this driver software" button five times, the installation

procedure is completed basically,while a dialog box will pop up . Please check

carefully if all the programs are installed. (check method: examine the bar of Driver

Nane , if all things are matching that means the software is installed successfully, if

there are X number or! number that means installation is unsuccessfully.Finally,

click "Finish."

12

(11) Click the Finish button, then the "Next" button in the main page begin to lit.

Left-click the "Next" button, then the Replicatorg printing software installation was

completed.

3.2.2 Software Description

(1) Connect the machine to the electricity supply., then connect USB and open

replicator, (Choose The Replicator Dual machine for the first double nozzles and the

Replicator Single for the first single nozzle)

13

(2) Next is to choose the correct serial port (Please note the machine's serial number is

often not com1)

(3)Click online

(4)And then select the file you want to print:

14

Then there will be the design of the file:

(5)Open the Control Panel

15

Set the nozzle temperature : set enter key in the box of Target Tempriture

Due to different temperature conductivity of different machines, there are a relatively

large differences between the temperature. It would be best to try out the wire from

215 degrees,. The temperature rises rapidly, reaching 190 degrees, indicating the large

heating allowance, otherwise the small heating allowance. If there is some trouble in

the process of wire, the temperature may not be enough. If the wire has

bubbling noises, that means the temperature is high. From low to high, set a suitable

temperature according to the actual situation. If you click the “reverse”, Extrusion

head motor will reverse, the almost completely used materials will be sent back. Shear

new material flatly,stuff it into the hole .After that, click stop, then click forward.

Extrusion head motor is transferred, it is needed to insert a little tight so that the

material is bitten, then send the nozzle until the spinning. Please note, it won't

continue to down to the bottom of the surface until the temperature arrive at a

predetermined value when we print.

How to start printing:

Move the figure to the appropriate location, click on the button below

16

Selection:

Please note that the above options, click Generate Gcode then Gcode is generated . After

generating gcode, move the print head to the home position

17

You can modify Feedrate (mm / s) to 20, Tralvel Feedrate 20 to have a higher accuracy

printing.

How to calibrate (normally do not need calibration):

Move the nozzle to the place just stick to the platform through the control panel

Tips after running:

Click OK, then the machine will calibrate the procedure automatically.

Click OK, and then disconnect , reconnect and the correction is completed.

Generate gcode print:

Click ,then the machine will start printing.

18

Please note, it won't continue to down to the bottom of the surface at the place of 10mm until

the temperature arrive at a predetermined value when we print.

3.2.3 Install the driver software of Makerware

(1) take out SD card and read the printer driver inside it , looking for the folder of

3dsetup

(2) Open 3dsetup folder and look for the file of software

(3) Right-click the file of the software and then enter into the software installation manager

(4)Click “ Makerware ”.There will be software-driven system that match to different

computer. To find suitable printer drivers that correspond to your own computer system.

Then click automatic installation

19

(5) Click automatic installation of the Makerware software.After a icon appears,then click

"Next" button.

(6) And then click "Next" button

20

(7)Then click the “I Agree” button.

(8)After clicking the “I Agree”button ,there will be a dialogue box ,please click Next

Table of contents