10

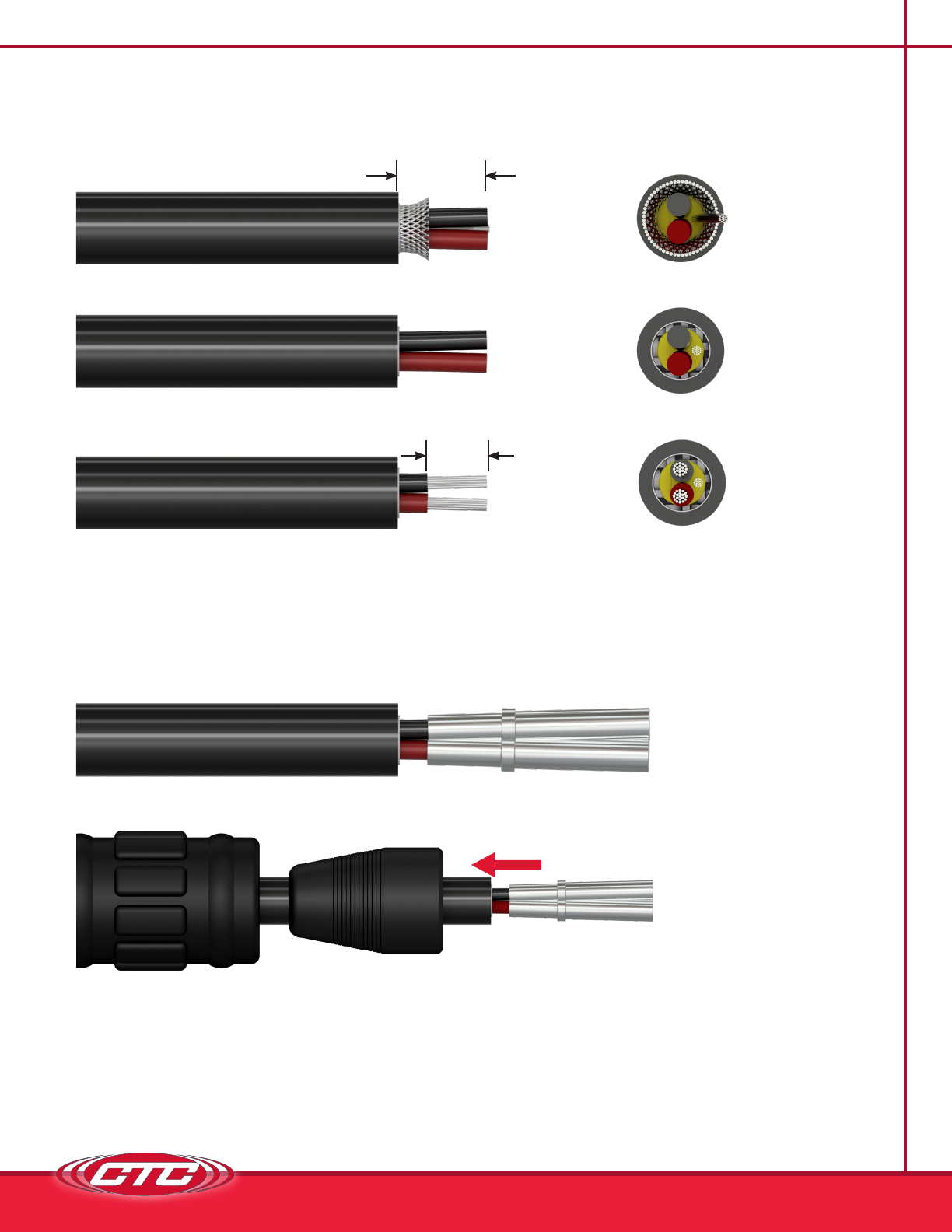

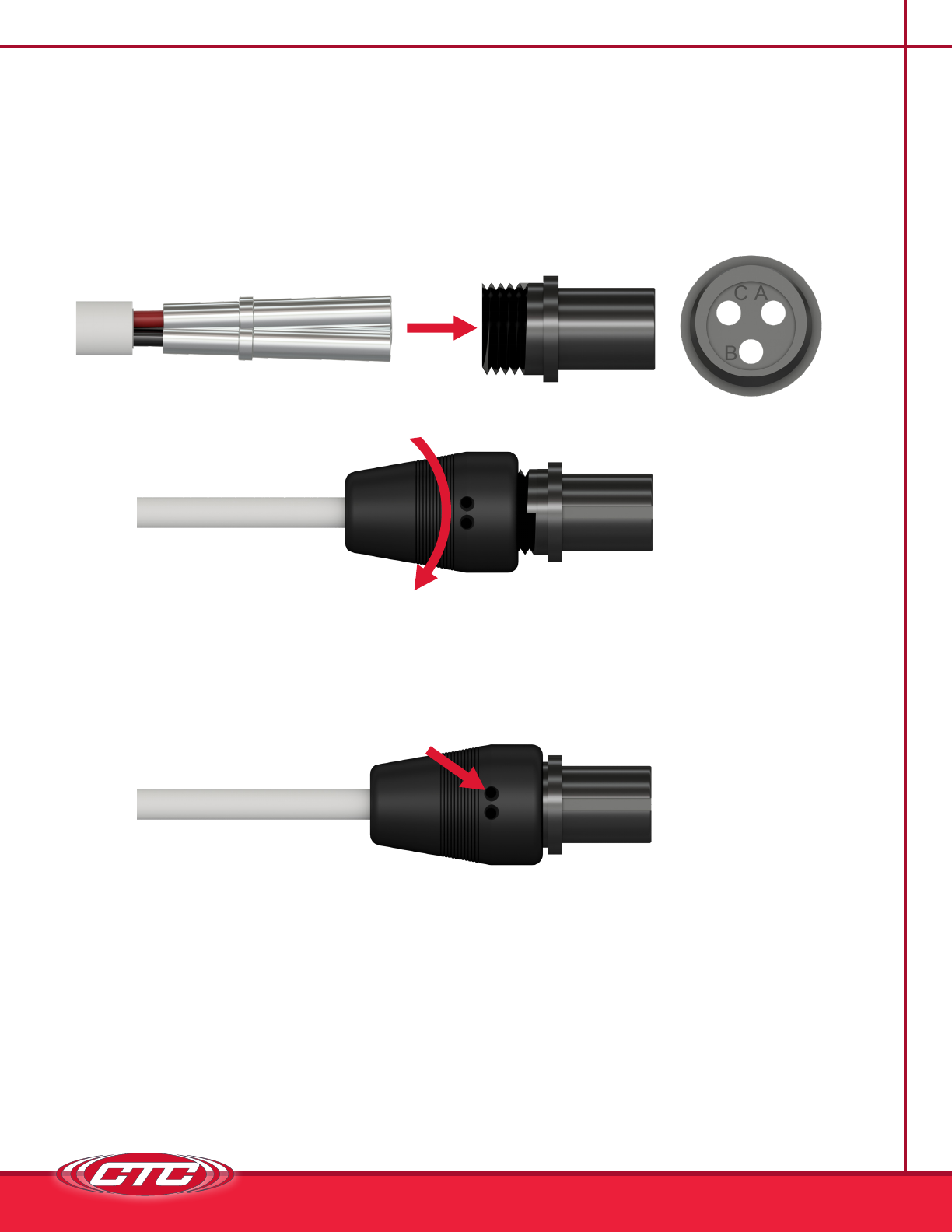

6. Attach O-ring to the front of the insert.

7. Using a fine-tipped punch, gently press each contact into the appropriate

position on the insert.

a. Install accelerometer red (+) wire into the insert socket for Pin A.

b. Install accelerometer black (-) wire into insert socket for Pin B.

c. Install accelerometer white (+) wire into the insert socket for Pin C.

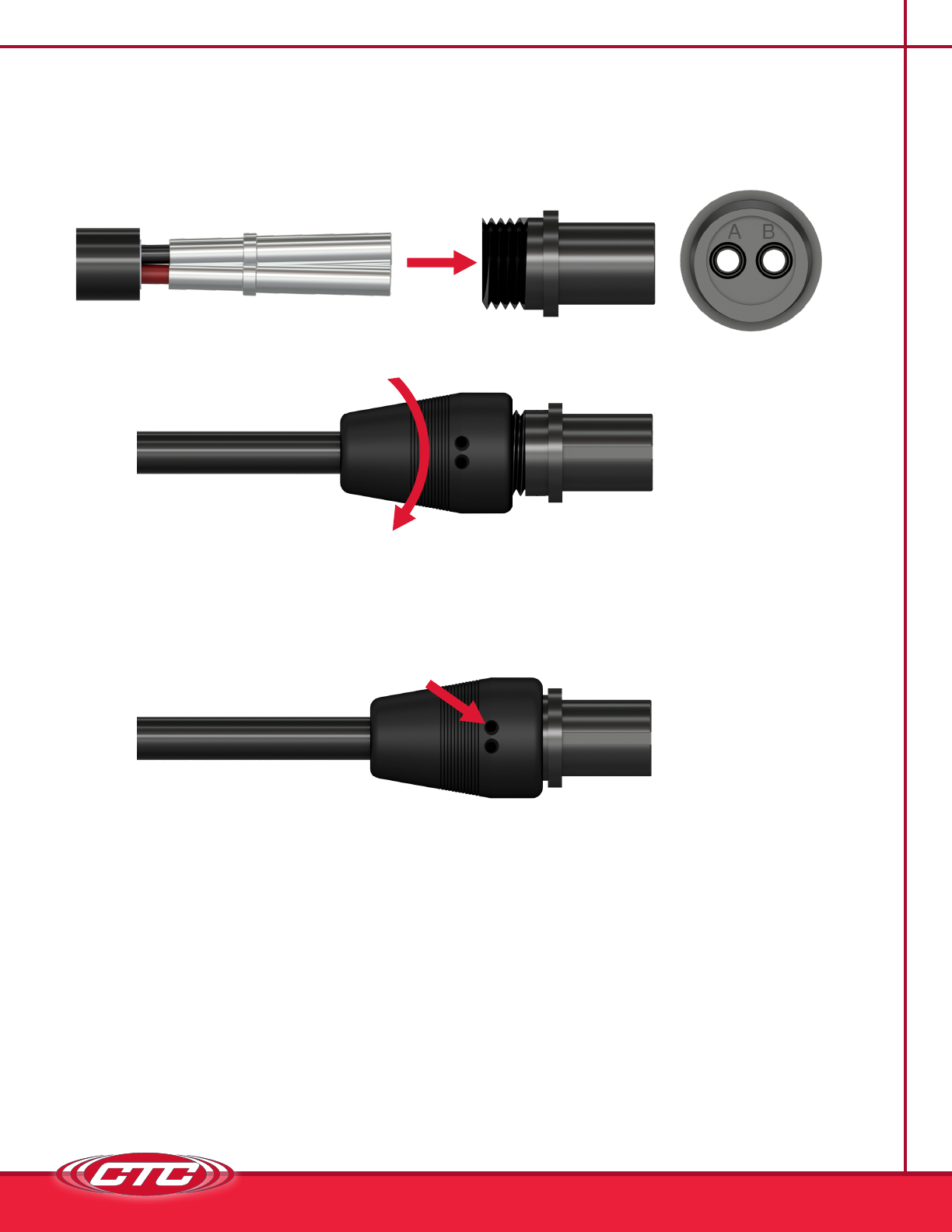

8. Thread the backshell onto the insert.

9. Place the assembled connector body horizontally with the two small epoxy

injection holes level and facing upward.

10. Mix epoxy. Using a syringe, fill the backshell with epoxy through one of the

small injection holes until epoxy begins to seep from the other.

11. Keep the connector in a horizontal position, allowing the epoxy to set and

vent any trapped air, refilling as needed.