10 GG-VL2-R

Specications

Input Power: +24 VDC, 85 mA

Detection Principle: Solid-state

Detection Method: Diusion

Gas: CFC / HFC / HCFC refrigerants (R11, R12, R22,

R134a, R404a, R410a, R434a, R507a, etc.)

Range: 0/1% (10,000 ppm)

Output Signal:

Linear 4/20 mA (max input impedance: 700 Ohms)

Deadband: 12 mA or 50% full-scale

Response Time: T90 = less than 30 seconds

Accuracy: +/- 5% of full-scale

Zero Drift: Less than 1% per month

Span Drift: Less than 1% of full-scale per month

Linearity: +/- 5% of full-scale

Repeatability: +/- 5% of full-scale

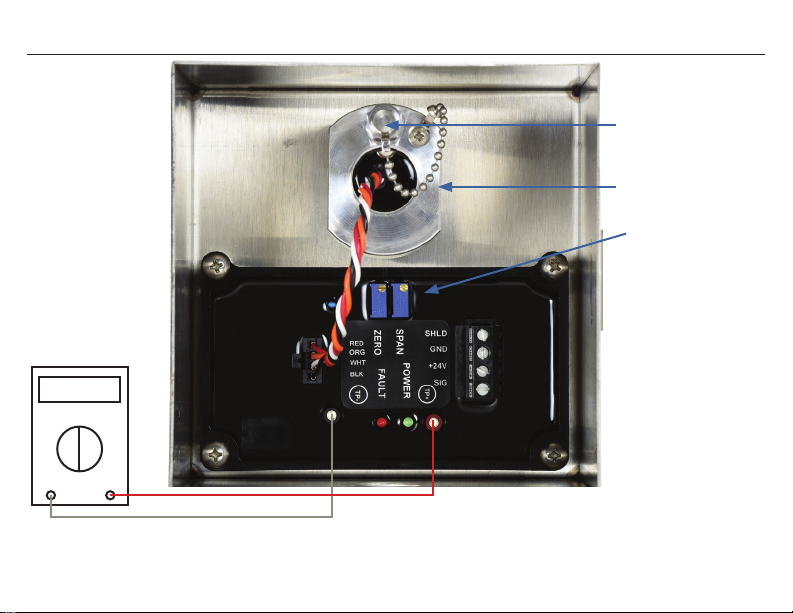

Wiring Connections:

3-conductor, shielded, stranded, 20 AWG cable

(General Cable C2525A or equivalent) up to 1500 ft.

Terminal Block Plug (Field Wiring): 26-16 AWG,

torque 4 lbs-in.

Enclosure: 18 gauge stainless steel housing. Captive

screw in hinged lid. For non-classied areas.

Mounting Kit: Schedule 80 NPT pipe ttings

Temperature Range: -46°F to +140°F (-46°C to +60°C)

Dimensions: 5.48” high x 4.90” wide x 2.93” deep

Weight: 4 lbs (includes mounting kit)

Certication:

SGS Listed:

Conforms to UL 61010-1

Certied to CSA C22.2 No. 61010-1

Troubleshooting

Sensor Fault: (low signal reading)

Indications: (any or all)

• Red LED on transmitter lit.

• Voltage signal at testpoints is 5 mVdc (.5 mA output).

• PLC displays negative value (e.g. -2150 ppm).

• Controller indicates sensor fault or sensor failure

Possible Cause / Solution:

• Sensor exposed to liquid. Replace sensor element

(see page 9 for more info).

• Loose connection. Check and tighten sensor wires.

Constant or Intermittent high signal or alarms:

Indications:

• Erratic or constant high concentration reading at

controller or PLC.

Possible Cause / Solution:

• Weeping relief valve. Check valve by drawing a

sample from the header with an accurate portable

refrigerant detector. Be sure to sample 1’ to 3’ from

inside the header to ensure a good reading.

• or loosen union nut and remove sensor assembly

from header. If signal returns to normal in fresh air,

investigate relief valve(s) and replace if necessary.

• Condenser steam. Re-install the ½“ plug or install

pipe in its place, lowered below the condenser

steam level to allow a fresh-air vent to the sensor.

• Sensor aged beyond its useful life (hypersensitive).

Replace sensor element (see page 9 for more info).