~

j

i

SECTION

1 TABLE OF CONTENTS

DESCRIPTION

•••••••••••••••••..••••••••...••••••.•..•••••••.•••.•••....••••••••••.••••..

1

A.

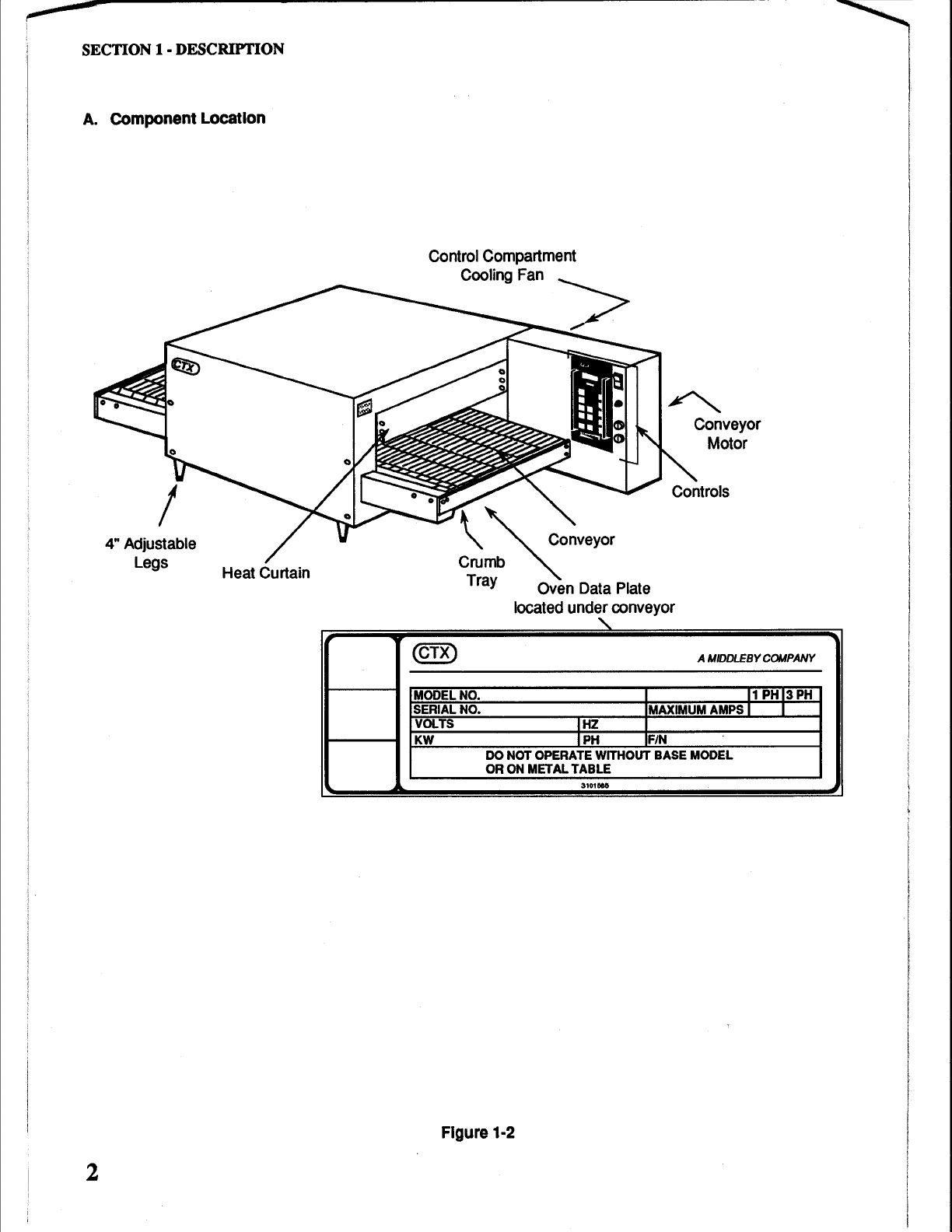

Component Location ................................................................2

B.

Component

Function

................................................................3-4

C.

Oven

Specifications .................................................................

5-8

D.

Dimension

Drawings

................................................................7

SECTION

2

INSTALLATION ............................................................................9

A.

Inspect For Shipping

Damage

..................................................9

B.

Placement of

Oven

...................................................................9

C.

Unpacking

Oven

.......................................................................

10

D.

Uncrating

Oven

........................................................................

11

E.

Installing

Legs

..........................................................................

11

F.

Stacking

and

Mounting

Two

Ovens

..........................................

12

G.

Stacking a single

G-26

oven

over a Toastmaster C0-19

convection oven or a

Blodgett

CTB-1

convection

oven

........

13

H.

Conveyor

Belt

and

Temperature

Display

.................................

14

I.

Standoffs ............................................................................

15

J. Electrical Connection ................................................................

15

K.

Heat

Curtains ...........................................................................

16

L.

Exit

Tray ............................................................................

16

SECTION

3

OPERATION ............................................................................17

A.

Location of Controls .................................................................

17

B.

Control Operation

And

Programming

.......................................

18

C.

Cooking

in

a

CTX

Oven

...........................................................

25

1.

Infrared

Cooking

Technology.......................................

25

2.

Heat

Zoning

.................................................................

25

3.

General

"Rules

of

Thumb"

...........................................

26

4.

Cooking Trials ..............................................................

26

5.

Time

and

Temperature

Guide

......................................

27-30

6.

Loading

the

Conveyor..................................................

31

Production

Chart

..............................................................

32

SECTION

4

MAINTENANCE ............................................................................

33

.

A.

Cleaning the Cooling

Fan

Filter................................................

33

B.

Cleaning

the

Oven

Chamber

....................................................34

C.

Cleaning "Loose"

Parts

............................................................

35

D.

Cleaning the Exterior................................................................

37

E.

Spare

Parts

Kit .........................................................................37

SECTIONS

TROUBLESHOOTING

••••••.••••••..•••••..•••.••.•..•••.•.•.•••••...•••....••••....•••••••••

39

Troubleshooting Chart 1 -Oven

is

Dead

......................................

39

Troubleshooting Chart 2 - Conveyor

Does

Not

Run

.....................

39

Troubleshooting Chart 3 -

Conveyor

Runs

Full

Speed

.................

40

Error

Codes

............................................................................

40

SECTION

6

PARTS LIST ............................................................................

41

Heating

Elements

and

Thermocouple

.........................................

.41

Conveyor,

Control

Panel

and

Loose

Parts

...................................

42-,43

Conveyor Motor

and

Electrical

Components

................................

44-45

SECTION

7

ELECTRICAL

SCHEMATICS

&

WIRING

...........................................

47

Schematic

208/240VAC,

1

Ph,

50/60Hz.......................................

48

Wiring

Diagram

208/240VAC,

1

Ph,

50/60Hz

...............................49

Schematic

380VAC,

3

Ph,

50Hz

...................................................

50

Wiring

Diagram

380VAC,

3

Ph,

50Hz

...........................................

51

iii