9

ASSEMBLY

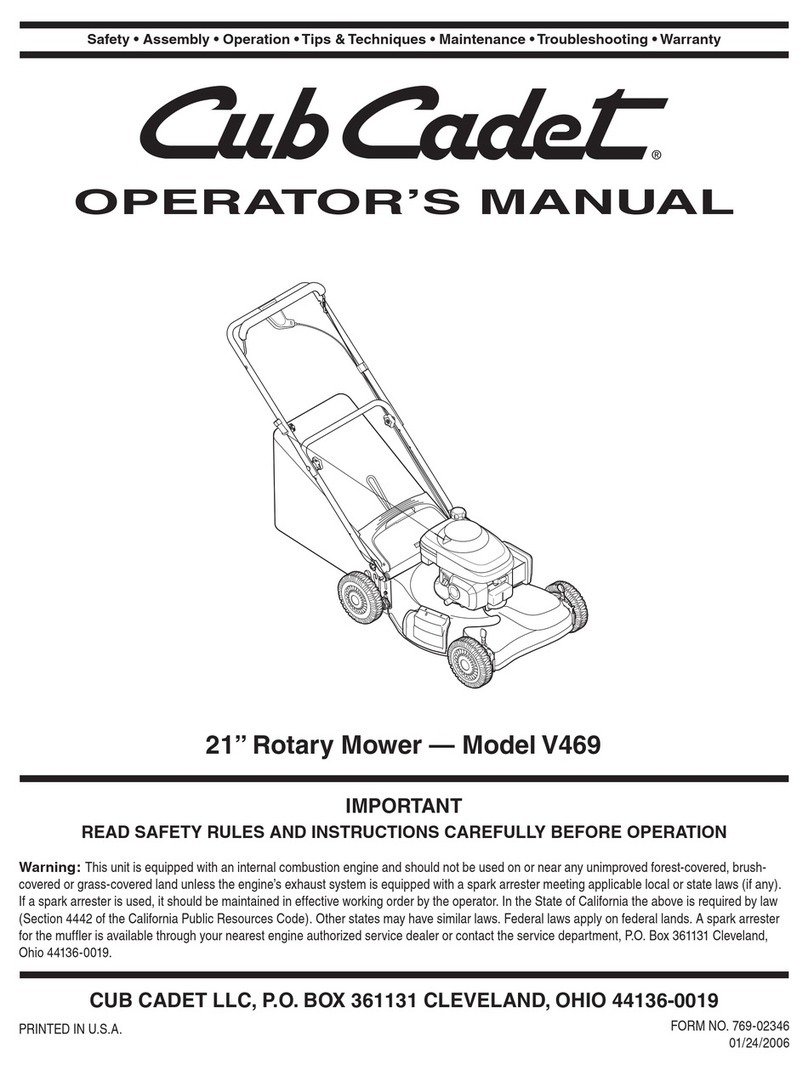

8. Insert the shoulder screw into the chosen index hole on the front gauge

wheel bracket.

NOTE: On the left side and right side deck gauge

wheels, the shoulder screw must be installed

from the outside of the tractor inward, through

the square hole on the bracket. On center deck

gauge wheels (if equipped) the shoulder screw

side of the assembly can be installed from either

direction. See Figure 16.

9. Secure with the lock nut

previously removed.

Battery Information

WARNING

CALIFORNIA PROPOSITION 65 WARNING: Battery posts, terminals, and

related accessories contain lead and lead compounds, chemicals known to

the State of California to cause cancer and reproductive harm. Wash hands

after handling.

WARNING

Should battery acid accidentally splatter into the eyes or onto the skin,

rinse the affected area immediately with clean cold water. Seek prompt

medical attention.

If acid spills on clothing, first dilute it with clean water, then neutralize

with a solution of ammonia/water or baking soda/water.

NEVER connect (or disconnect) battery charger clips to the battery while

the charger is turned on, as it can cause sparks.

Keep all sources of ignition (cigarettes, matches, lighters) away from the

battery. The gas generated during charging can be combustible.

As a further precaution, only charge the battery in a well ventilated area.

Always shield eyes and protect skin and clothing when working

near batteries.

Batteries contain sulfuric acid and may emit explosive gases. Use extreme

caution when handling batteries. Keep batteries out of the reach

of children.

CAUTION

When attaching battery cables, always connect the POSITIVE (Red) wire to

the terminal first, followed by the NEGATIVE (Black) wire.

NOTE: The positive battery terminal is marked Pos. (+). The negative battery

terminal is marked Neg. (–).

Connecting Battery Cables

WARNING

Always connect the positive lead to the battery before connecting the

negative lead. This will prevent sparking or possible injury from an

electrical short caused by contacting the tractor body with tools being

used to connect the cables.

For shipping reasons the factory may leave both battery cables disconnected from

the terminals. To connect the battery cables, proceed as follows:

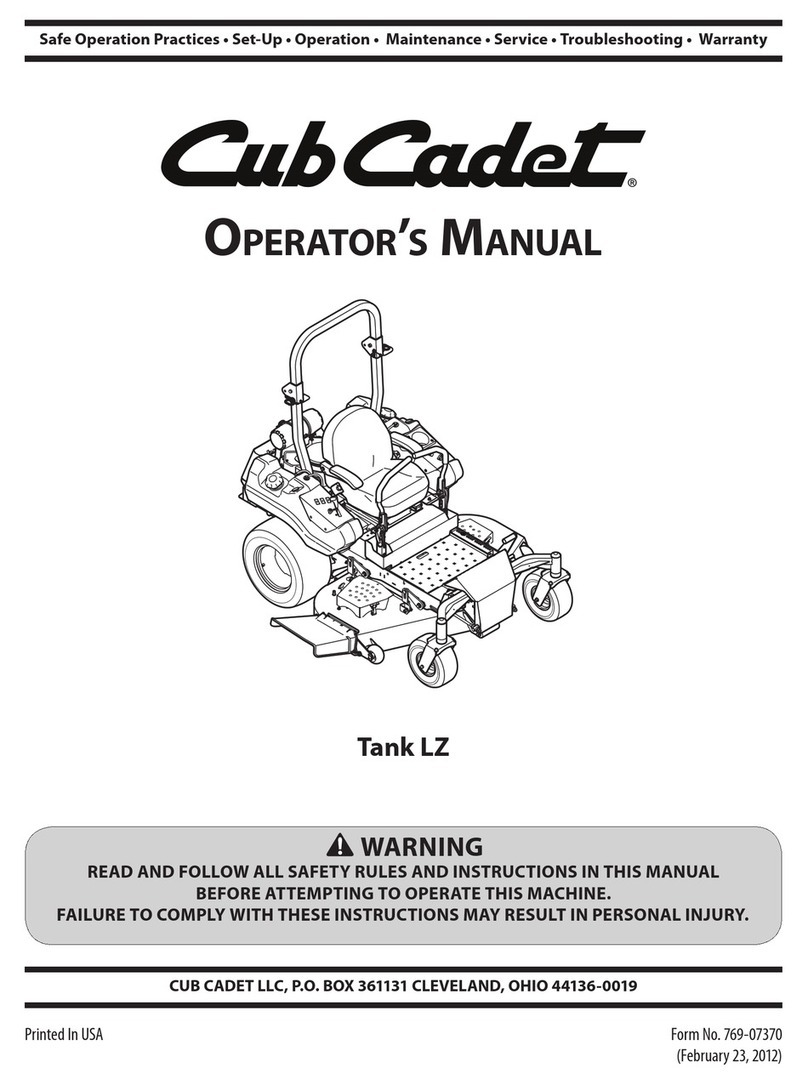

1. If present, remove the plastic cover from the positive battery terminal.

Attach the red connector to the positive battery terminal (+) using the bolt

(a) and hex nut (b). See Figure 17.

Outer bracket

Inner bracket

Figure 16

(b)

(b)

(a)

(a) (c)

Figure 17

2. If present, remove

the plastic cover

from the negative

battery terminal

and attach the black

cable to the negative

battery terminal

(–) with the bolt (a)

and hex nut (b). See

Figure 17.

3. Position the red

rubber boot (c) over

the positive battery

terminal (+) to help

protect it from corrosion. See Figure 17.

NOTE: If the battery is put into service after date shown on top/side of battery,

charge the battery as instructed in the Service and Maintenance section, prior

to operating.

Battery Maintenance

• The battery is filled with battery acid and then sealed at the factory.

However, even a “maintenance free” battery requires some maintenance to

ensure its proper life cycle.

• Spray the terminals and exposed wire with a battery terminal sealer, or

coat the terminals with a thin coat of grease or petroleum jelly, to protect

against corrosion.

• Always keep the battery cables and terminals clean and free of corrosion.

• Avoid tipping. Even a sealed battery will leak electrolyte when tipped.

Battery Storage

• When storing the tractor for extended periods, disconnect the negative

battery cable. It is not necessary to remove the battery.

• All batteries discharge during storage. Keep the exterior of the battery clean,

especially the top. A dirty battery will discharge more rapidly.

• The battery must be stored with a full charge. A discharged battery can

freeze sooner than a charged battery. A fully charged battery will store

longer in cold temperatures than hot.

• Recharge the battery before returning to service. Although the tractor may

start, the engine charging system may not fully recharge the battery.

Battery Removal

WARNING

Battery posts, terminals, and related accessories contain lead and lead

compounds. Wash hands after handling.

The battery is located beneath the seat

frame. To remove the battery:

1. Remove the hex washer screw (a)

securing the battery hold-down

bracket (b) to the frame. Then flip

the battery hold-down bracket (b)

up to free the battery. See Figure 18.

2. Remove the hex cap screw and sems

nut securing the black negative

battery lead to the negative

battery post (marked NEG). Move

the cable away from the negative

battery post.

Figure 18