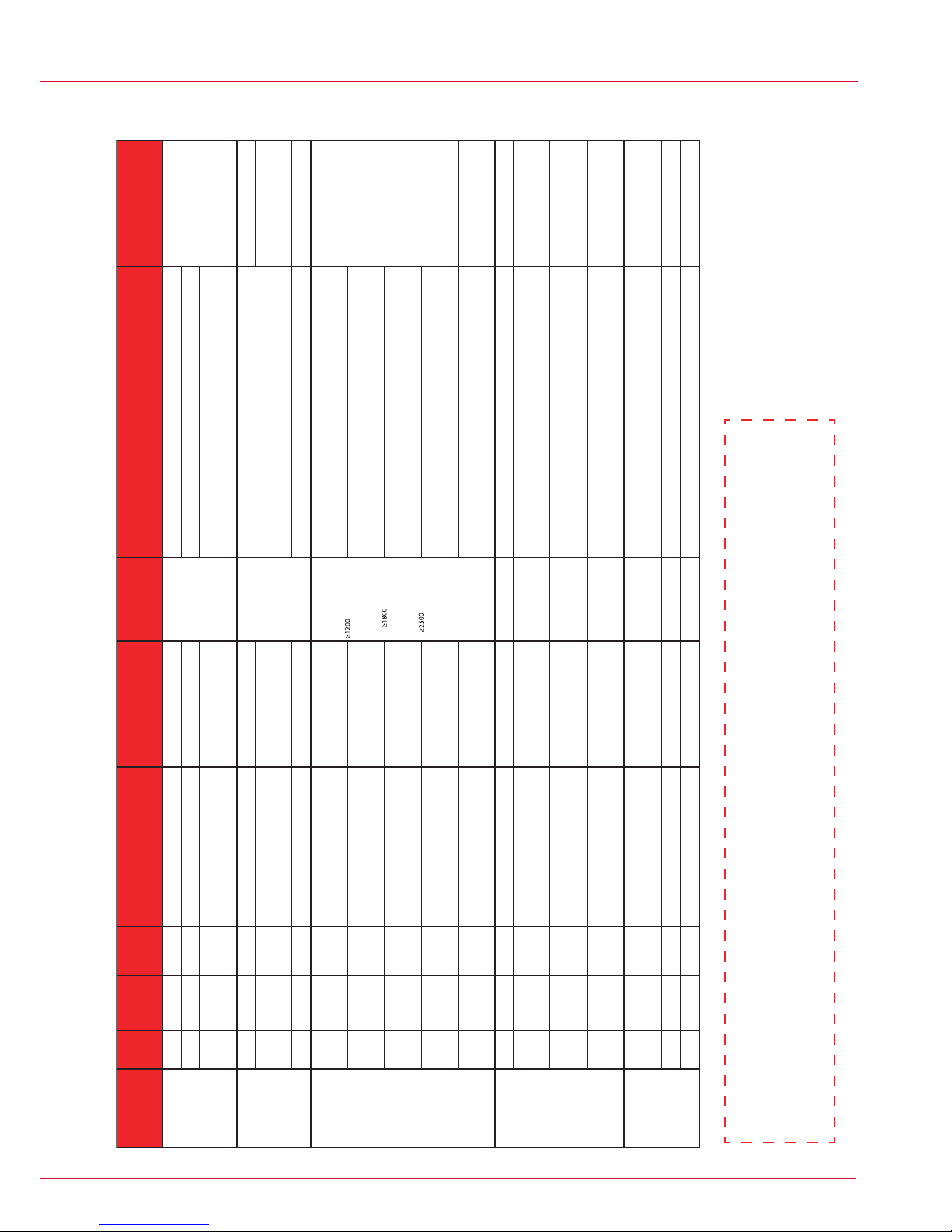

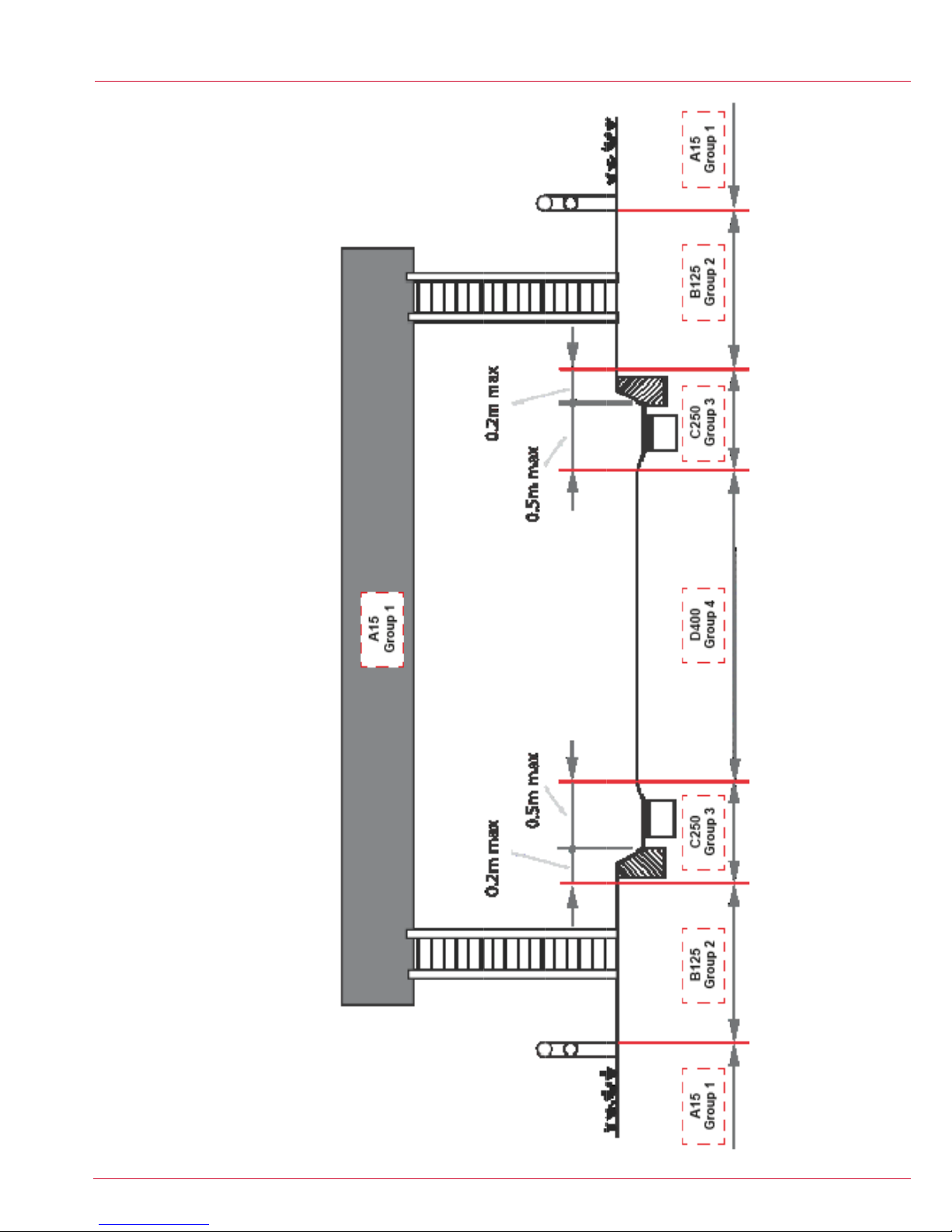

EN 124

Group

Recommended

minimum Cover

Class*

Maximum

Chamber

Depth

(mm)

Excavation Footprint Base Material Bracing Backfill Additional Information.

1A15 1200100mm or width of compacting equipment50mm of compacted stone (MOT1) Compacted MOT1 stone, or as dug material if of a granular type.

2B125 1200100mm or width of compacting equipment100mm of compacted stone (MOT1) Compacted MOT1 stone or lean mix concrete.

3 C250 1200150mm or width of compacting equipment150mm of lean mix concrete (C40) Minimum 150mm C40 concrete

4 D400 2000200mm or width of compacting equipment 150mm of lean mix concrete (C40),

reinforced with A393 mesh.Minimum 200mm C40 concrete

1A15 1200100mm or width of compacting equipment50mm of compacted stone (MOT1)

2B125 1200100mm or width of compacting equipment100mm of compacted stone (MOT1)

3 C250 1200150mm or width of compacting equipment150mm of lean mix concrete (C40) Minimum 150mm C40 concrete

4 D400 2000200mm or width of compacting equipment 150mm of lean mix concrete (C40),

reinforced with A393 mesh.Minimum 200mm C40 concrete

1A15 2400150mm or width of compacting equipment50mm of compacted stone (MOT1) Sidewall length < 1500mm As dug if granular is ok, otherwise compacted MOT1 stone.

Sidewall length between 1500 and 2500mm compacted MOT1 stone.

Sidewall length > 2500mm minimum 150mm C40 Concrete

2B125 2400150mm or width of compacting equipment100mm of compacted stone (MOT1) Sidewall length < 2500mm compacted MOT1 stone

Sidewall length > 2500mm minimum 150mm C40 concrete

3 C250 2400150mm or width of compacting equipment150mm of lean mix concrete (C40) Sidewall length < 2500mm compacted MOT1 stone

Sidewall length > 2500mm minimum 150mm C40 concrete

4 D400 2400 200mm or width of compacting equipment 150mm of lean mix concrete (C40),

reinforced with A393 mesh. Minimum 200mm C40 concrete

5E600 2400200mm or width of compacting equipment

250mm of lean mix concrete (C40),

reinforced with 2 layers A393 mesh

equally spaced.

Minimum 250mm C40 concrete

1A15 1200100mm or width of compacting equipment50mmof compacted stone (MOT1) Bracing required on

chambers with side wall Compacted MOT1 stone, or as dug material if of a granular type.

2B125 1200100mm or width of compacting equipment100mm of compacted stone (MOT1)

Bracing required on

chambers with side wall

lengths greater than

600mm.

Compacted MOT1 stone or lean mix concrete.

3 C250 1200150mm or width of compacting equipment150mm of lean mix concrete (C40)

Bracing required on

chambers with side wall

lengths greater than

600mm.

Minimum 150mm C40 concrete

4 D400 2000200mm or width of compacting equipment 150mm of lean mix concrete (C40),

reinforced with A393 mesh.

Bracing required on

chambers with side wall

lengths greater than

600mm.

Minimum 200mm C40 concrete

1A15 2000100mm or width of compacting equipment50mm of compacted stone (MOT1) No requirement for

bracing. Compacted MOT1 stone

2B125 2000100mm or width of compacting equipment100mm of compacted stone (MOT1) No requirement for

bracing.

Compacted MOT1 stone or in areas where additional stability is required lean mix

concrete can be used.

3 C250 2000150mm or width of compacting equipment150mm of lean mix concrete (C40) No requirement for

bracing. Minimum 150mm C40 concrete

4 D400 2000200mm or width of compacting equipment 150mm of lean mix concrete (C40),

reinforced with A393 mesh.

No requirement for

bracing. Minimum 200mm C40 concrete

Double bracing, equally

spaced

mm single central

bracing, required in both

directions.

mm double

bracing at equal

spacing.

mm bracing at

600mm spacing using

acrow props, both

horizontally and vertically

.

Minimum 100mm C40 concrete

Ultima

Hydrant Sections require only a

granular backfill. Final adjustment is

not necessary, 25mm sections

available. Split base/dog kennel

arrangment around infrastructure.

TSSL base section do not require to

be concreted, minimum depth of

450mm upto 900mm

French Telecom

SNCF

Motorway Communications

approved, total system available from

sump base, bracketry and cover.

Bracing required on

chambers with side wall

lengths greater than

600mm.