User Manual Interfaces

www.cuesystem.com

Page 3 of 44

Table of Contents

1. Introduction .................................................................................................................................... 4

1.1. Overview................................................................................................................................................. 4

1.2. Models .................................................................................................................................................... 4

1.3. Features ................................................................................................................................................. 4

1.4. Programming .......................................................................................................................................... 4

2. Mounting......................................................................................................................................... 5

3. System Connection by CUEring................................................................................................... 6

3.1. Overview................................................................................................................................................. 6

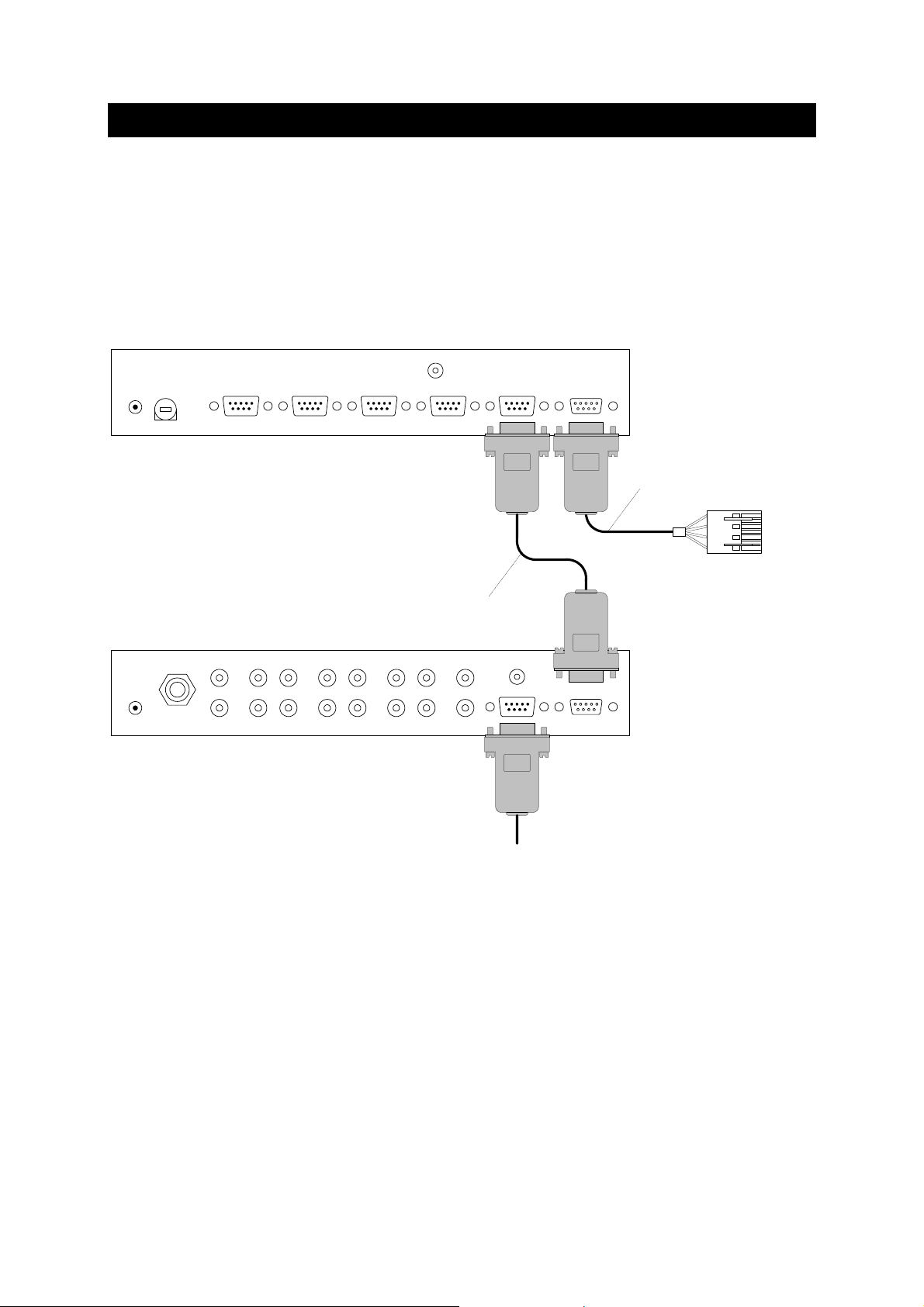

3.2. CUEring Connection ............................................................................................................................... 7

3.3. Using O-ring Cable ................................................................................................................................. 8

4. Power Supply ................................................................................................................................. 9

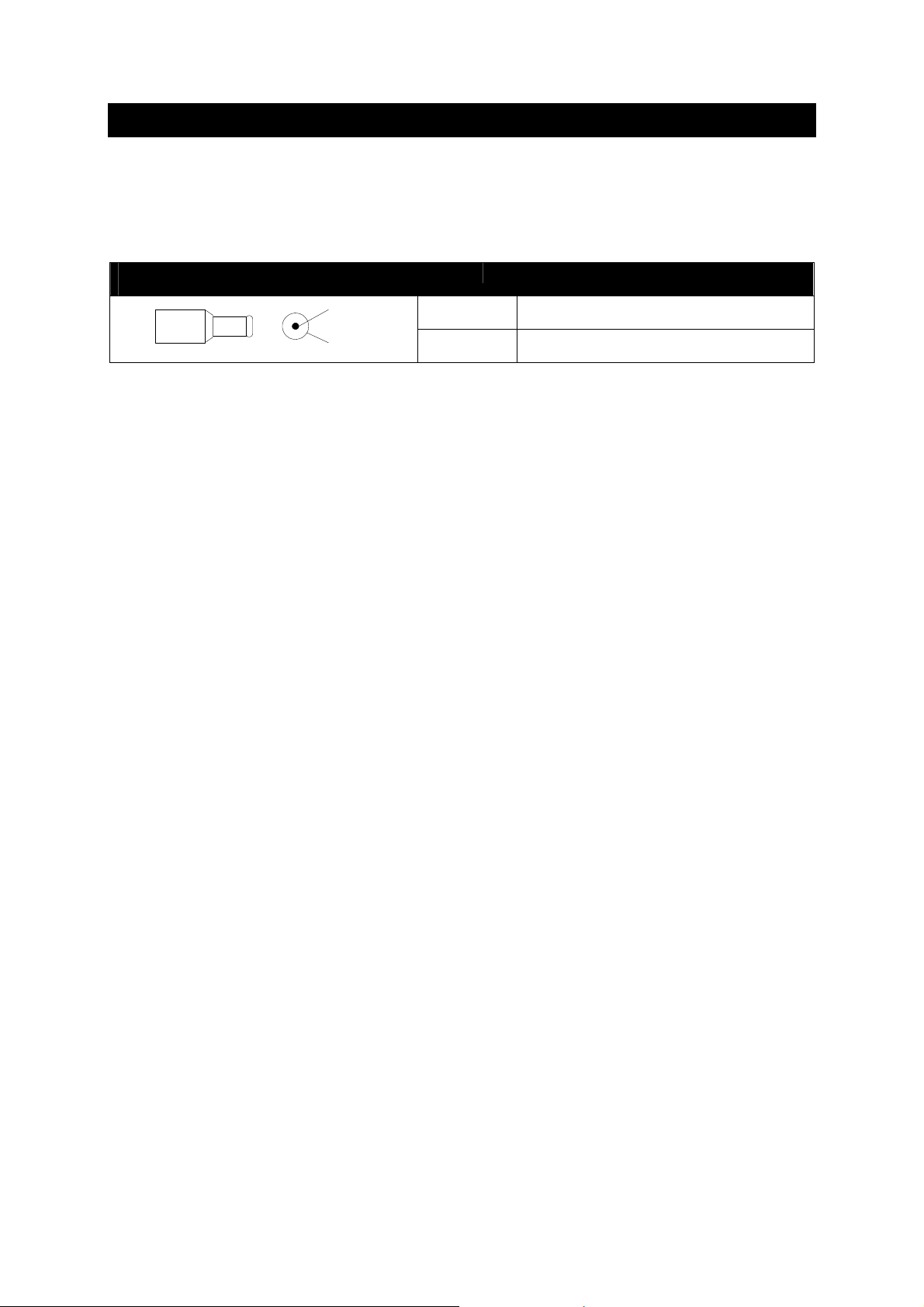

4.1. Power Input ............................................................................................................................................ 9

4.2. Power consumption ................................................................................................................................ 9

4.3. Fuse........................................................................................................................................................ 9

5. smartCUE...................................................................................................................................... 10

5.1. Overview................................................................................................................................................10

5.2. IR Control - EPROM Preparation...........................................................................................................12

5.3. Rear Panel Connections........................................................................................................................13

5.4. Front Panel Description .........................................................................................................................17

5.5. Diagnostic..............................................................................................................................................19

5.6. Specifications and Mechanical Drawings...............................................................................................20

6. soundCUE..................................................................................................................................... 21

6.1. Overview................................................................................................................................................21

6.2. Rear Panel Connections........................................................................................................................22

6.3. Front Panel Description .........................................................................................................................23

6.4. Setup by DIP Switch..............................................................................................................................24

6.5. Diagnostic..............................................................................................................................................25

6.6. Specifications and Mechanical Drawings...............................................................................................26

7. analogCUE.................................................................................................................................... 27

7.1. Overview................................................................................................................................................27

7.2. Rear Panel Connections........................................................................................................................27

7.3. Front Panel Description .........................................................................................................................29

7.4. Diagnostic..............................................................................................................................................30

7.5. Specifications and Mechanical Drawings...............................................................................................31

8. auxCUE ......................................................................................................................................... 32

8.1. Overview................................................................................................................................................32

8.2. Rear Panel Connections........................................................................................................................32

8.3. Front Panel Description .........................................................................................................................35

8.4. Setup by DIP Switch..............................................................................................................................37

8.5. Diagnostic..............................................................................................................................................37

8.6. Specifications and Mechanical Drawings...............................................................................................38

9. Software and Firmware License................................................................................................. 39

10. Warranty Conditions ................................................................................................................... 40

11. CE Declaration of Conformity..................................................................................................... 41

12. FCC................................................................................................................................................ 42