10 M898-3_GB_letter

NEB 6500 and NEB 6500 R

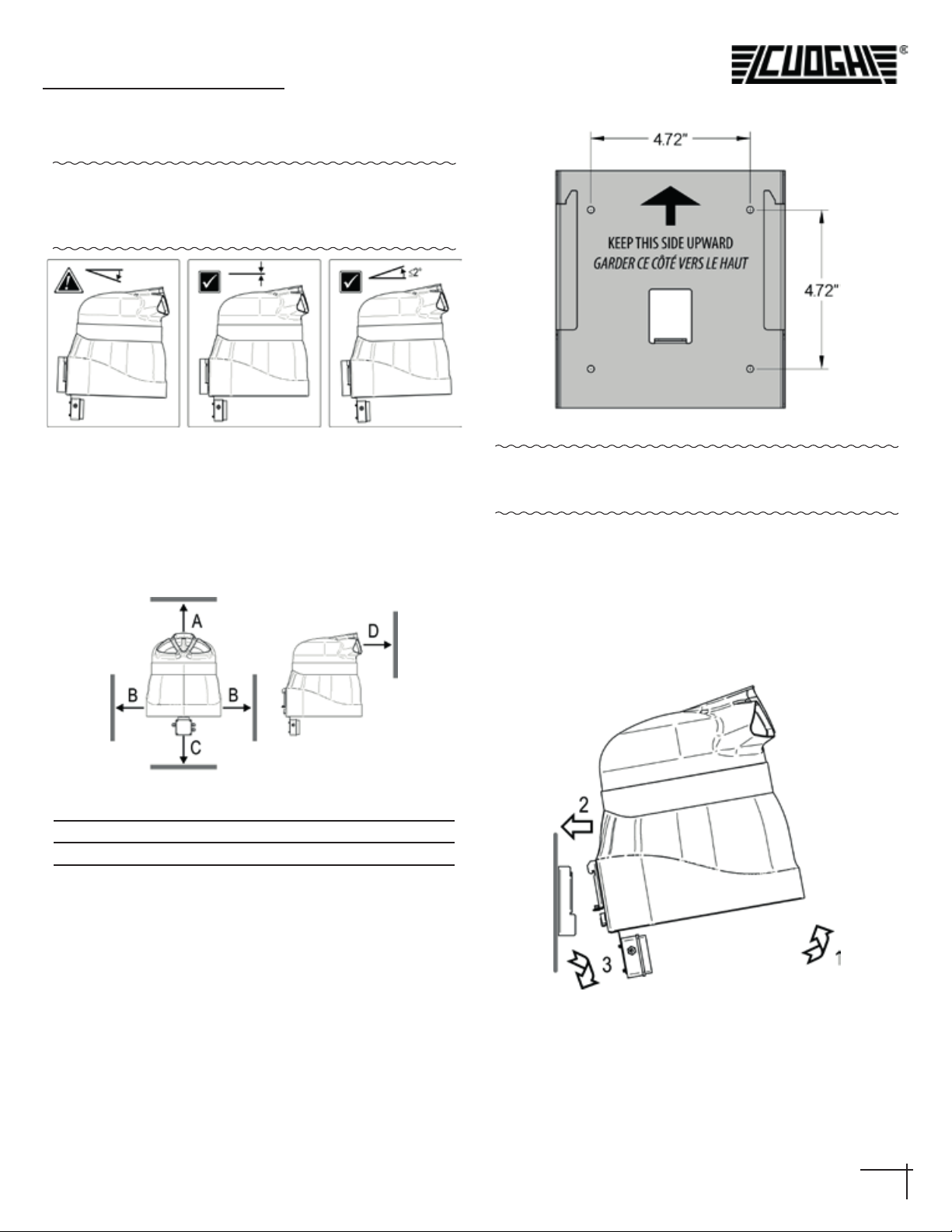

to a water tap B, or to an extension. It is advisable to install

a mechanical lter Cdown-line of the tap B, as shown in

Pic.14.

For the water drain use the plastic pipe Dsupplied or one

that is similar having a 0.39 inches internal diameter. e

pipe must be installed as shown in Pic.14 with a minimum

slope of 10°, to guarantee the correct drainage of the water.

A siphon Emust be on the main drain and not on the

drainpipe connected to the machine.

To guarantee regular drainage of the water, make sure

that the drainpipe has a slope and is straight, without any

bends or constrictions. e end of the drain tube must be

“in air” to prevent any back pressure.

Pic.15 - Details of the end of the drain tube.

WARNING! Any failure in the drainage can cause water

dripping from the humidier.

4.5 Final operations

»Direct the outlets of the air diuser. To do this, loosen

the screw that holds the diuser on top of the machine,

and turn the diuser: at the end of the operation block

the screw again.

»Check that the hydraulic connections have been prop-

erly installed. Open the water supply tap and check that

there are no leaks along the supply circuit

5.1 Preliminary checking

Before starting up the humidier check that:

1. All the connections, both electrical and hydraulic, have

been done according to the instructions found in this

manual.

2. ere are no leaks.

3. e air lter is tted.

4. e water supply tap is open.

5. e distribution inlets are correctly positioned.

WARNING: prolonged use of the machine without water

supply can seriously damage the solenoid valve.

5.2 Starting

To start the humidier turn on the main switch. e

machine will perform a washing cycle lasting about one

minute, as described in detail in par. “6.3 e washing/reset

cycle”. At the end of the cycle, if the humidistat contact is

closed, the humidier starts the motor and water atomiza-

tion begins.

IMPORTANT: e humidier will start to atomize the

water only if the H-H contact is closed.

During operation check if the water is drained regularly. If

it should be necessary to adjust its humidication capacity,

follow the instructions indicated in par. “6.2 Adjusting the

humidication capacity”.

WARNING: if the humidier works in a room with over

saturated humidity the air lter can impregnate reducing

the air ow. Use an humidistat or a timer to avoid this

situation.

5.3 Stopping

To stop the humidier:

1. Take the humidistat to the minimum % R.H. value so

that the corresponding ON/OFF contact is opened.

2. Wait for about one minute to give the machine the time

to carry out the washing cycle.

3. Open the main electrical power switch;

4. Close the water supply tap.

WARNING: if the main switch is opened while the machine

is atomizing the electronic board will NOT perform the

washing cycle and the basin will NOT be emptied.

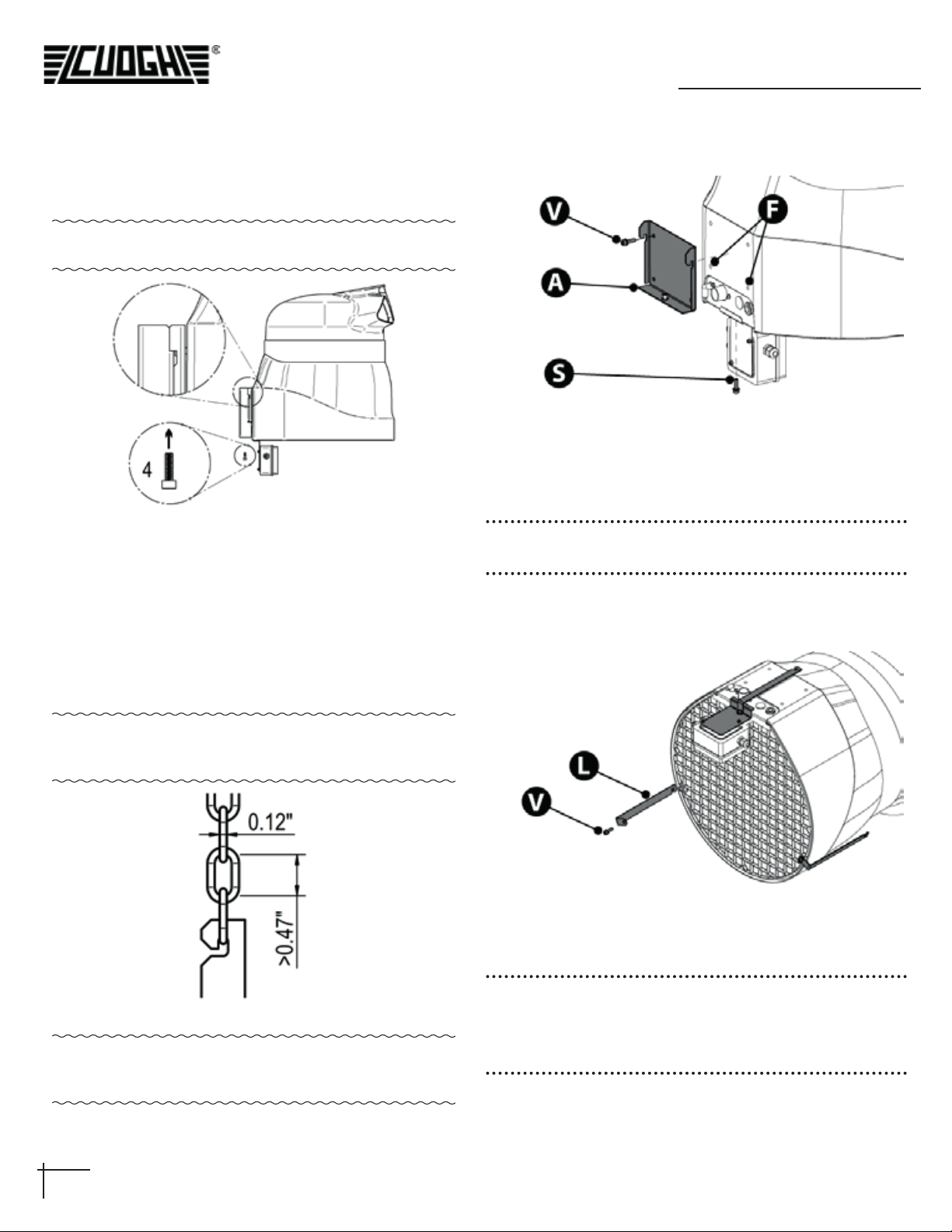

6.1 e electronic board

e operation of the NEB 6500 is controlled by the elec-

tronic card, that has the following functions:

»Adjustment of the humidication capacity.

»Starting and stopping of the washing/reset cycle.

e regulation of the capacity is made with dip-switches.