7

OPERATING INSTRUCTIONS

Read and understand the operating and safety manual

for this pump prior to use.

NEVER operate the pump in an explosive atmosphere.

NEVER operate the pump in wet or damp locations.

DO NOT expose to rain.

Hydraulic fluid under pressure can easily puncture skin

causing serious injury.

ALWAYS wear approved safety glasses when operating or

servicing this pump.

ATTENTION: This pump is shipped from the factory with an unvented fill plug

to prevent leakage. Prior to use, remove the unvented fill plug and

install the vent plug provided. Failure to install the vent plug will

result in poor performance.

IMPORTANT: Starting the motor without the cylinder properly attached to

the pump will cause the pump to immediately build an internal

pressure of 10,000 P.S.I. To depressurize the hydraulic system,

first unplug the power cord then rotate the valve lever to the open

position and allow the hydraulic cylinder to fully retract. Slowly

disconnect the hydraulic hose.

1. Ensure the unvented fill plug that was used during shipping has been removed

and the vented fill plug provided has been installed.

2. Check the oil level in the reservoir. Add approved hydraulic oil if necessary.

(See “Adding Hydraulic Oil” section on page 10).

3. Rotate the pump valve lever to the open position.

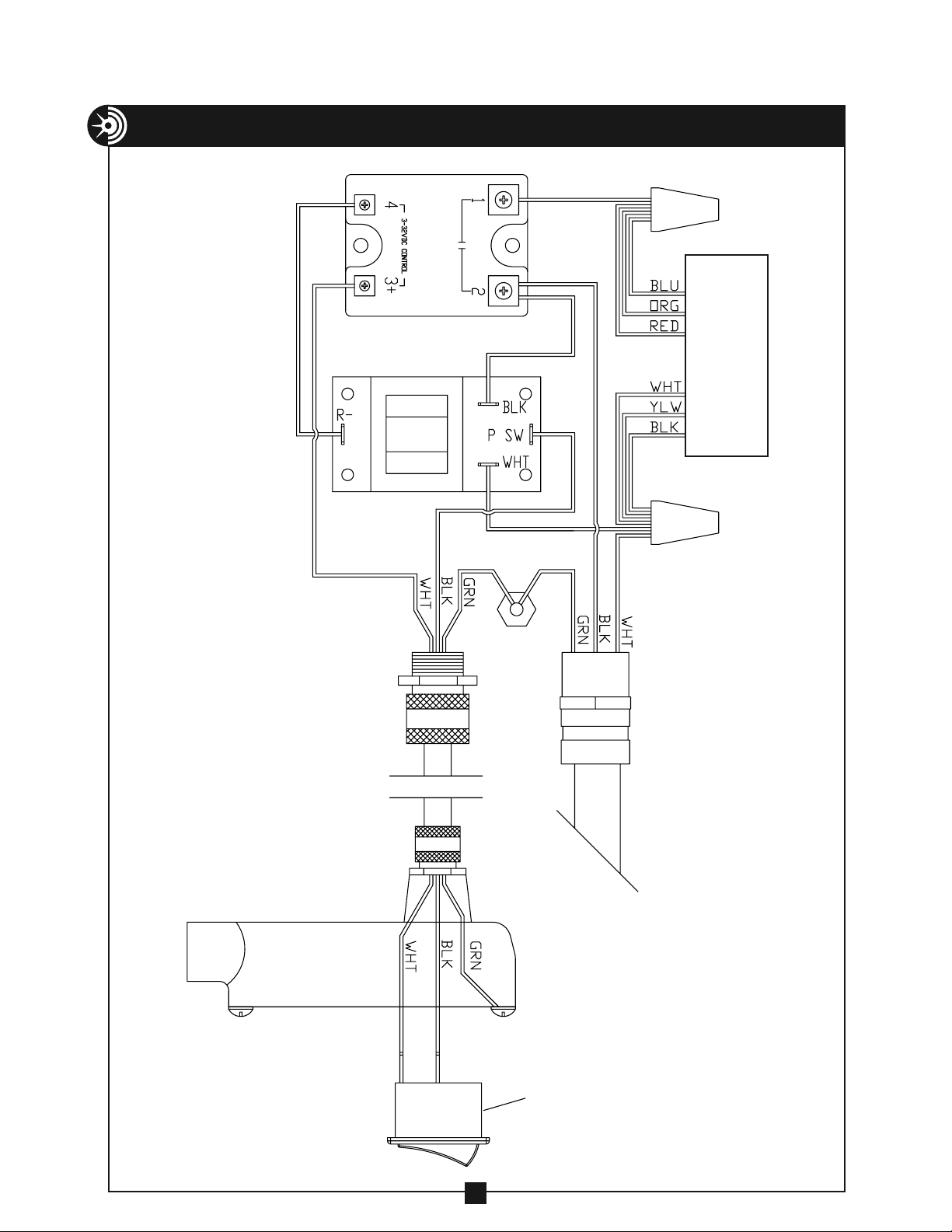

4. Ensure that the hose and couplings are clean and free of debris prior to

assembly.

5. Attach the hydraulic hose to the coupling assembly on the hydraulic cylinder

and the coupling on the hydraulic pump. Hand tighten all connections firmly.

DO NOT use tools.

6. Plug the pump into the correct power supply.

To advance the hydraulic cylinder

1. Rotate the pump valve lever to the closed position.

2. Depress the jog switch on the pendant assembly.

To retract the hydraulic cylinder

Rotate the pump valve lever to the open position to release the pressure

Removing the hydraulic cylinder

Prior to removing the hydraulic cylinder that is connected to the pump, the system

must be depressurized.

1. Unplug the power cord.

2. Rotate the pump valve lever to the open position and allow the hydraulic

cylinder to fully retract.

3. Slowly disconnect the hydraulic hose.

DANGER

WARNING

DANGER

WARNING