Do not operate in wet or damp locations. Do not expose to rain.

Do not operate in a hazardous location or near combustible materials.

Keep all body parts, hair, loose clothing, etc. away from rotating parts and

pinch points. Also, stay clear of cable during operation as it approaches

and is fed through the Cable Feeder.

An emergency stop is provided on the Cable Feeder for your safety.

Always inspect before each use to ensure proper operation.

The Cable Feeder has no braking system. Do not use the Cable Feeder to

lift or lower any loads or personnel.

Unplug the Cable Feeder when loading cables to avoid accidental starting.

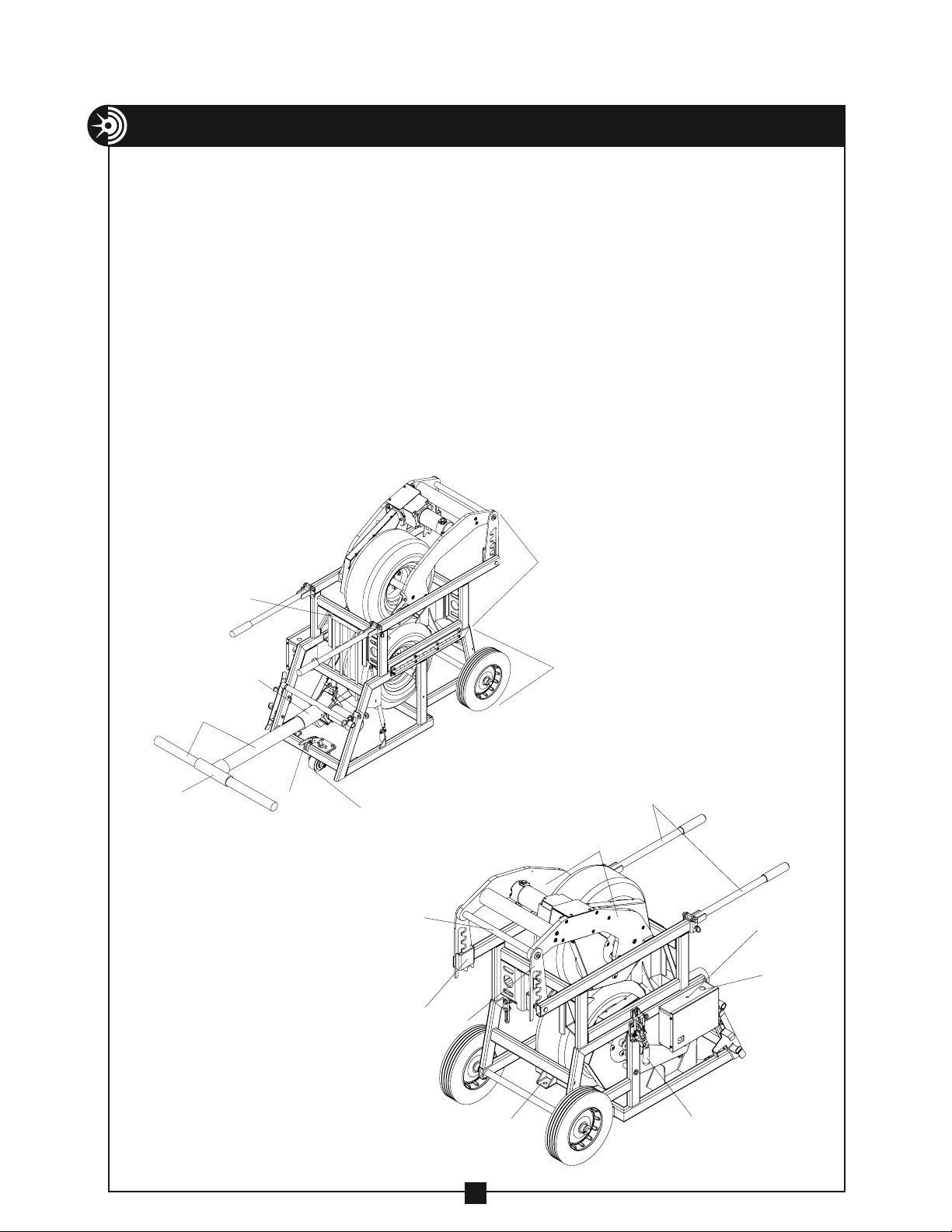

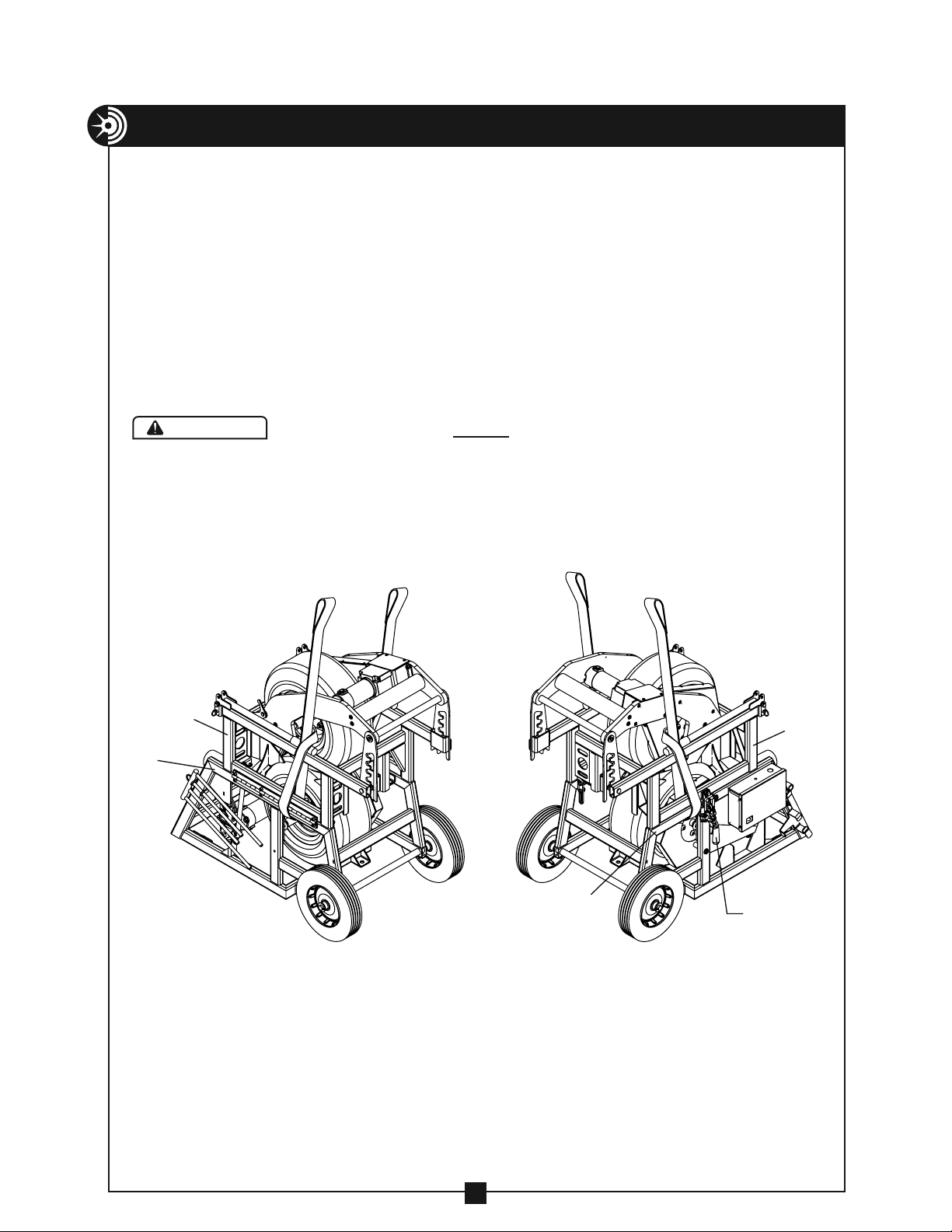

Upper drive clamp MUST be in closed, locked position before attempting

to lift the Cable Feeder. For instructions on lifting the Cable Feeder, see

Page 6.

Always plug the Cable Feeder into a grounded 115 VAC receptable with a

15 amp GFCI protected circuit. Do not modify the plug provided with the

Cable Feeder. Inspect the power cord before each use.

Unplug the Cable Feeder before servicing or maintenance.

Do not remove guards; they are installed for your protection.

The maximum cable diameter is 3.5". The maximum width of all cables in

the Cable Feeder is 6". Exceeding this width may cause the cables to run

off the tire causing cable damage.

Only use the Cable Feeder for its intended purpose to feed cable off of

cable reels as described in this manual. The Cable Feeder is not to be used

as a cable puller to pull cable or rope through conduit or in cable trays.

Only feed electrical cable through the tires of the Cable Feeder. Do not

allow any sharp objects to contact the tires; doing so may cause damage

to the tires and possibly tire failure.

Inspect the Cable Feeder for damage or wear before each use.

RETAIN SAFETY INFORMATION

3

3

IMPORTANT SAFETY INFORMATION

This manual should be read and understood by all personnel who operate

or service this Cable Feeder. Failure to understand how to safely operate

and service this unit could result in injury or death. This unit should only be

operated and serviced by qualified personnel.

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION