5

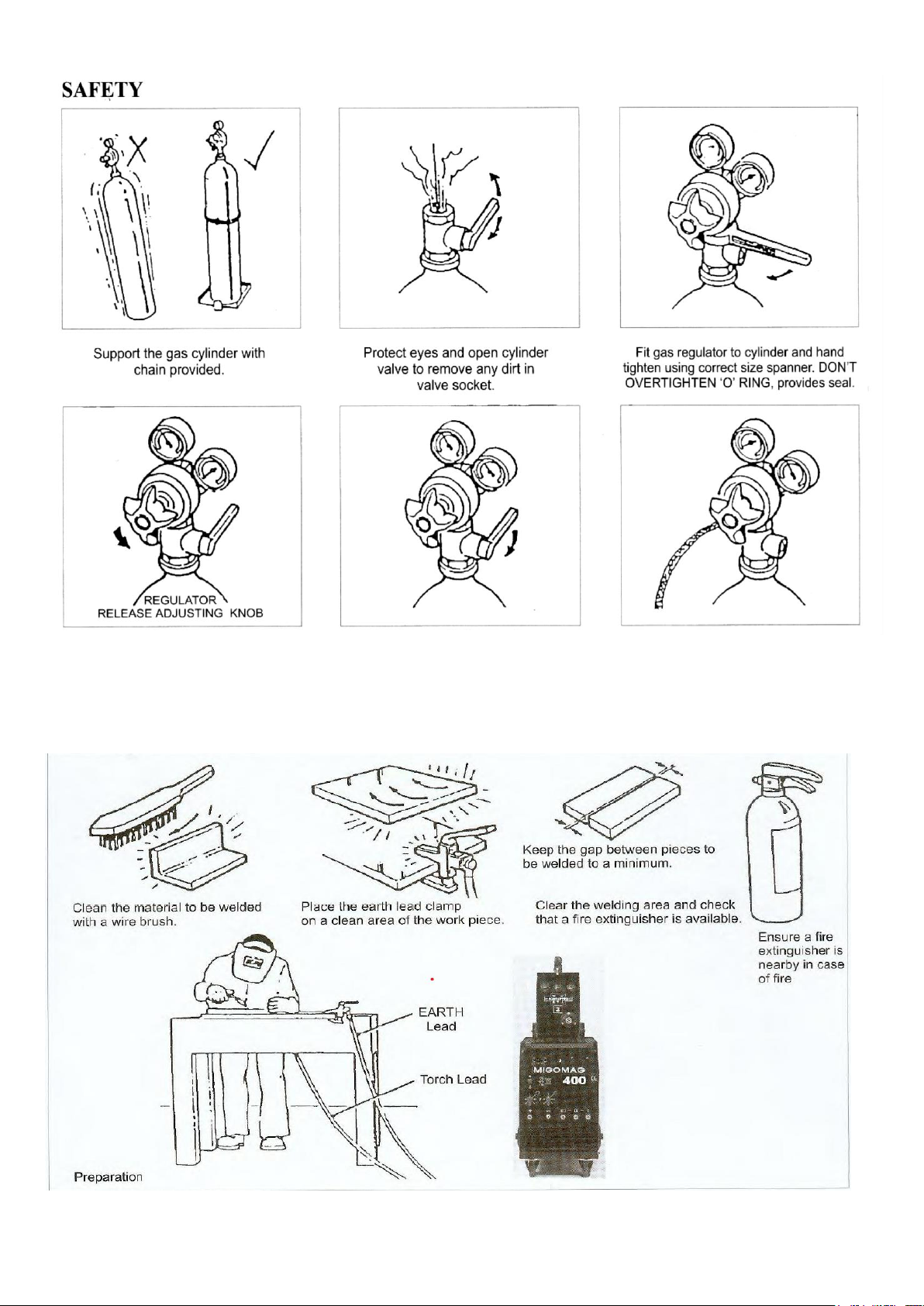

SHEILDING GAS

The gas provides a shield over the weld pool to prevent

contamination from the surrounding air. The shielding

gas also contributes to arc stability, weld strength and

appearance, so care should be taken to ensure that the

correct gas type/mixture is selected for the metal being

welded. (Refer table page 10)

The gas flow rate, adjusted by the regulator, increases

with variations in welding gun diameter and should be 15

litres per minute for the MB24 welding gun to 25 litresper

minute for the MB36 welding gun with cylindrical nozzle.

Excessive gas flow rates should be avoided as they are

wasteful and, in some instances, can cause weld

porosity.

WORK ENVIRONMENT

The machine should be used indoors away from strong

draughts which may cause gas dissipation.

If the machine is to be covered, the natural cooling air

circulation must not be interrupted.

Before commencing welding, clear area of flammable

materials.

OPERATION

1. Continuous Welding

Ensure that both timer switches ‘t1’ and ‘t2’ are in the

“OFF” position.

Set the voltage and wire feed controls to positions

suitable for welding the thickness of the material being

welded.

Welding current varies in direct relationship to wire feed

speed. For low welding current output, the wire feed

speed control should be set at the low end of the wire

feed speed scale.

Turning the wire feed speed control knob clockwise will

result in increased wire feed speed and welding current.

Welding voltage is adjusted to match the wire feed speed

(welding current).

For welding in the low current range, set both voltage

switches to position number (1). (number 1 on both

voltage switches for MIGOMAG 260, 350, 400)

These MIGOMAG machines have two voltage selection

switches, a course control (8) and fine voltage selection

(6).

Progressively select higher voltage positions with

increases in wire feed speed.

Low wire feed speed settings for a given voltage will

cause a large ball to form on the end of the welding wire

and cause excessive spatter.

High wire feed speed settings for a given voltage will

cause wire stubbing.

Position the torch over the seam to be welded with the

nozzle approximately 70° to the work surface.

The nozzle to work distance should be approximately

10mm.

WARN BYSTANDERS TO SHIELD THEIR EYES.

Lower your helmet and press the welding gun trigger

switch to initiate an arc.

As the weld is deposited, push the torch from right to left

direction, slowly along the seam at a constant speed.

Using the wire feed speed control, adjust for a “crisp”

sounding arc.

2. Spot Welding

MIG spot welding is made from one side of the sheets

placed upon another so that the high welding current

penetrates through the upper sheet (max. 1.5mm) and

a part of the lower sheet.

A circular spot is produced each time the torch trigger

is pressed. The spot weld time ‘t1’ can be varied.

Select ‘spot’ welding by turning switch ‘t1’ only.

Fit spot weld nozzle to the torch.

Set voltage and wire feed speed controls to near

maximum settings and carry out test welds on scrap

materials as follows:

Position the legs of spot-welding nozzle over weld

position and depress torch trigger switch. `At the

termination of the weld, check for weld penetration

(small dimple showing on underside of weld), and

adjust spot weld time for best results.

When welding sheets of unequal thickness, the thinner

sheet must be on top. Thicker sheets can be welded

together by drilling a hole in the top sheet and directing

the wire into hole –this is known as ‘plug welding’.

Spot welding requires ONLY LIGHT PRESSURE; the

sheets are pressed against each other with the legs of

the welding nozzle.

3. Stitch Welding

The wire feed output is switched on and off repeatedly.

This produces a lower heat input which is particularly

advantageous when welding thin or poor-quality

materials as well as bridging gaps.

Select ‘stitch’ welding by turning ’t1’ and ‘t2’ controls to

the halfway setting. Vary time to obtain the best results.

They do not have to be equal.

‘t1’ controls the welding or working cycle.

‘t2’ controls the pause cycle between welding.

Note: The trigger on the gun must be kept

depressed during both cycles.

Welding occurs during the working (ON) cycle; During

the pause cycle, the wire feed STOPS, and the arc will

extinguish. During the pause cycle the molten pool will

cool down. The arc will ignite again automatically at the

beginning of the following working cycle when the filler

wire makes contact with the molten pool. The welding

current is automatically switched on and off and the

shielding gas supply will remain on during the pause

cycle.

Note: Spot welding and stitch welding of

aluminium is not possible.