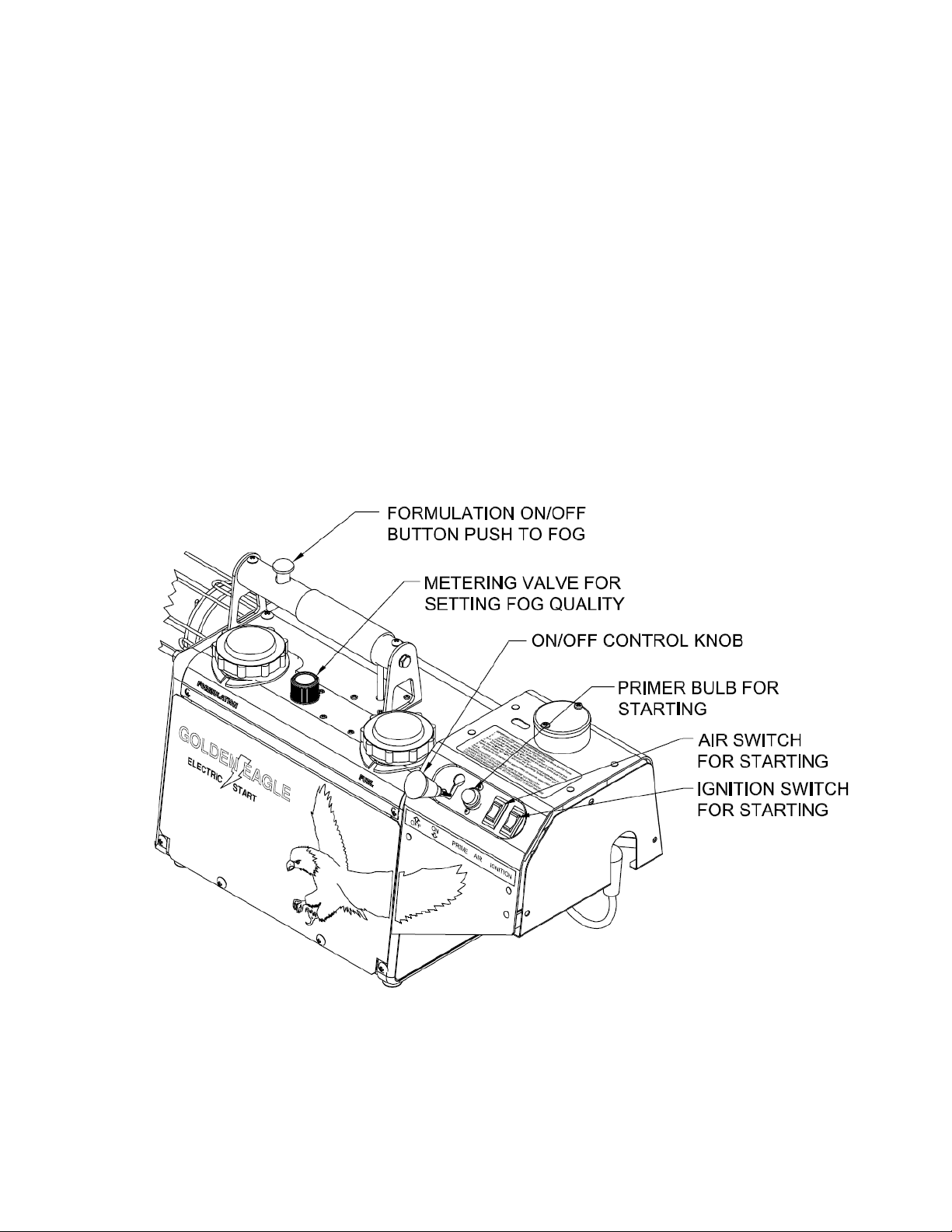

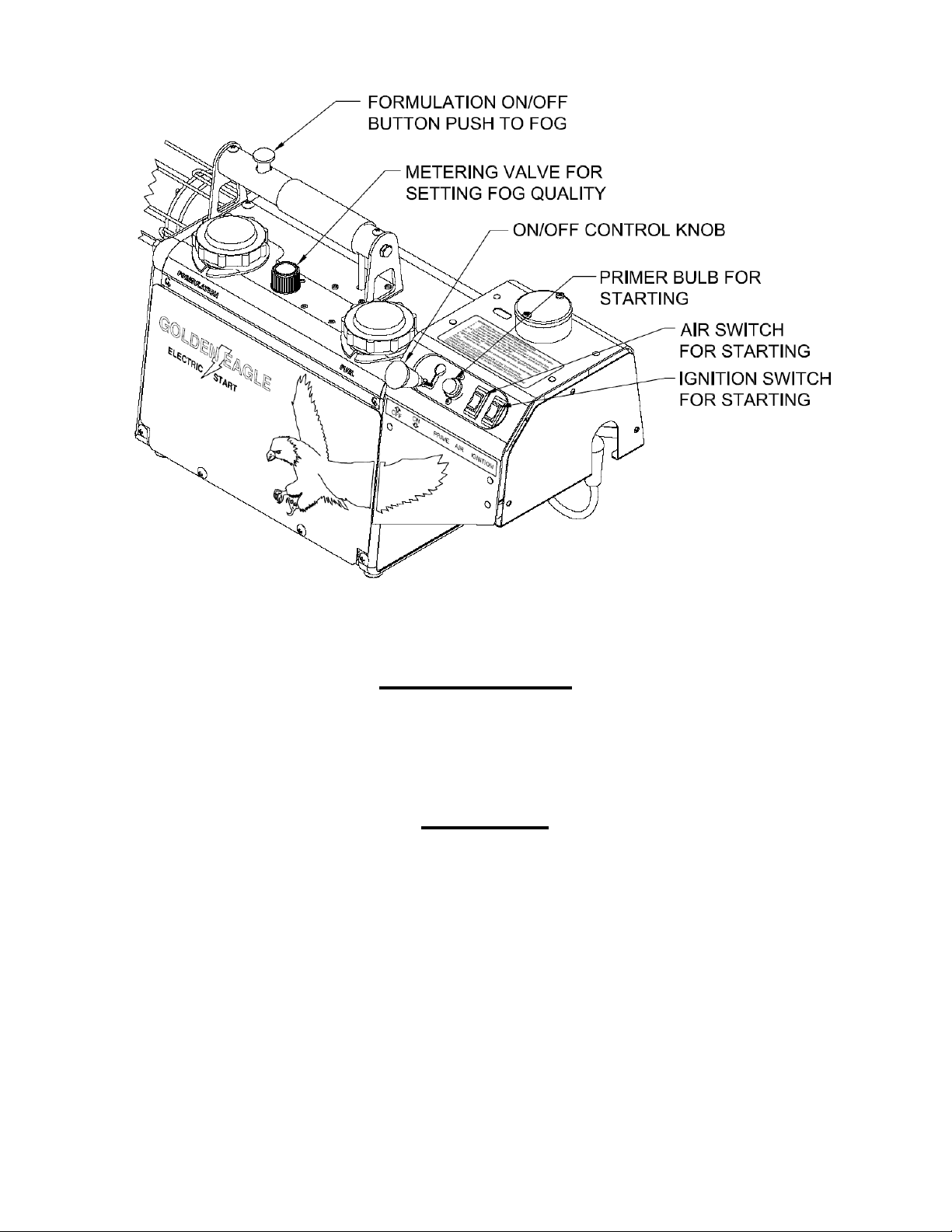

STARTING THE ENGINE

1. Verify that the FORMULATION ON/OFF button is released and that the

FORMULATION METERING VALVE has been rotated fully clockwise (CW) until the

Stop is reached.

.

2. Lift the ON/OFF Control and place it in the "ON" position.

WARNING

DO NOT LEAVE THE MACHINE UNATTENDED WITH THE ON/OFF CONTROL

IN THE ON POSITION, ESPECIALLY IF THE MACHINE HAS BEEN RUNNING.

IF THE ENGINE IS HOT AND THE ON-OFF CONTROL IS IN THE ON

POSITION, THE MACHINE MAY SELF START.

3. Press and hold the Ignition Switch and listen for the audible buzzing or clicking sound of the

Electronic Ignition firing the Spark Plug.

4. Depress and release the "Primer Bulb" repeatedly until the fuel is visible in the Bulb. Once fuel

reaches the Bulb. depress and release the Bulb (3) times for a "cold engine", (1) time for restarting a "hot

engine". (See Page 8 for starting conditions.)

CAUTION

Excessively depressing the primer bulb will flood the engine.

WARNING

FLOODING MAY RESULT IN A LOUD EXPLOSIVE SOUND AND CAUSE

SOME SMALL AMOUNT OF FLAME TO BE EMITTED FROM THE DISCHARGE

(EXHAUST) END OF THE ENGINE.

CAUTION

If flame emits from the discharge (exhaust) end of the engine tube, the engine

is flooded. STOP. See the section STARTING A FLOODED ENGINE.

5. Simultaneously press and hold the Ignition and Air Switches until the Engine begins to start.

6. Once the Engine starts, release the Air Switch and continue depressing the Ignition Switch, until

the Engine runs smoothly.

If the Engine has not started within approximately 40 seconds, repeat steps 4, 5, 6.

If the Engine does not start, and the sound of the Electronic Ignition is not heard, release the

IGNITION SWITCH and proceed to the TROUBLE SHOOTING section of this manual.

WARNING

DO NOT ACTUATE GASOLINE PRIMER BULB WITH ON/OFF CONTROL

KNOB IN OFF POSITION. DO NOT ATTEMPT TO START MACHINE WITH THE

CARBURETOR COVER REMOVED.

NOTE

“Flooded'' means that the fuel-air mixture around the spark plug has become

too rich (too much fuel/or the amount of air available) to ignite.

9