3

WARRANTY INFORMATION................................................................................................................................................. 4

PDF FILE FORMAT................................................................................................................................................................ 5

CAUTIONS AND WARNINGS................................................................................................................................................ 7

FOREWORD ........................................................................................................................................................................... 8

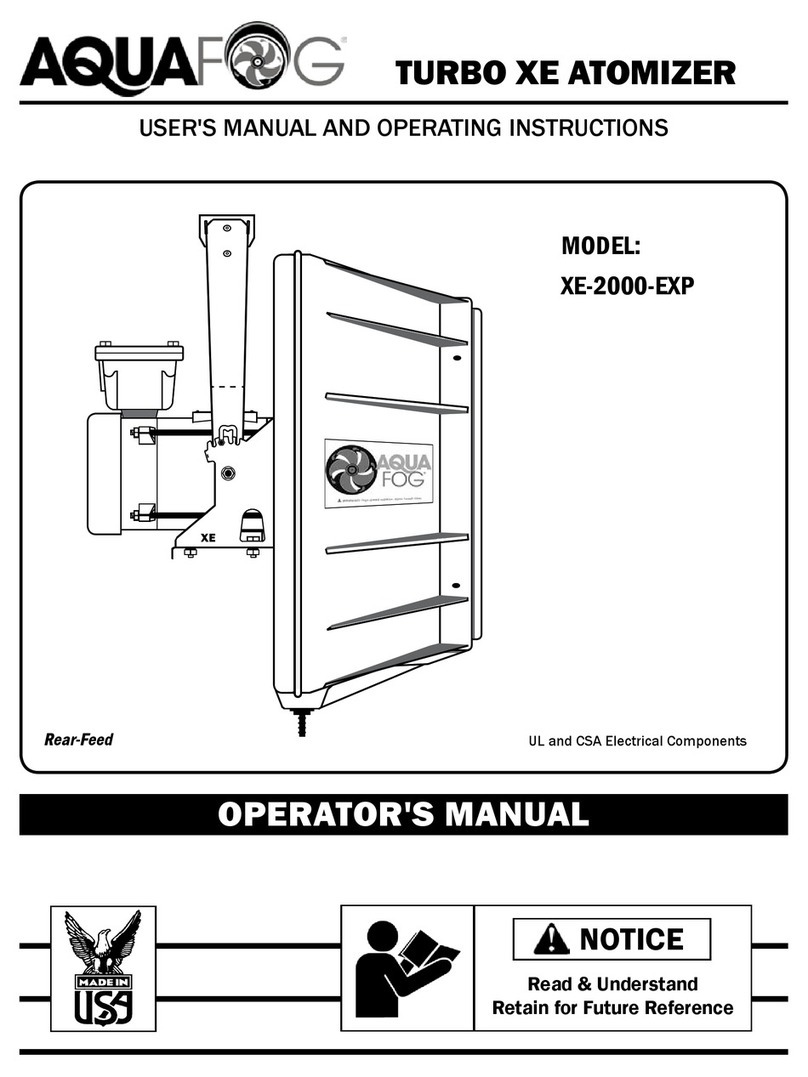

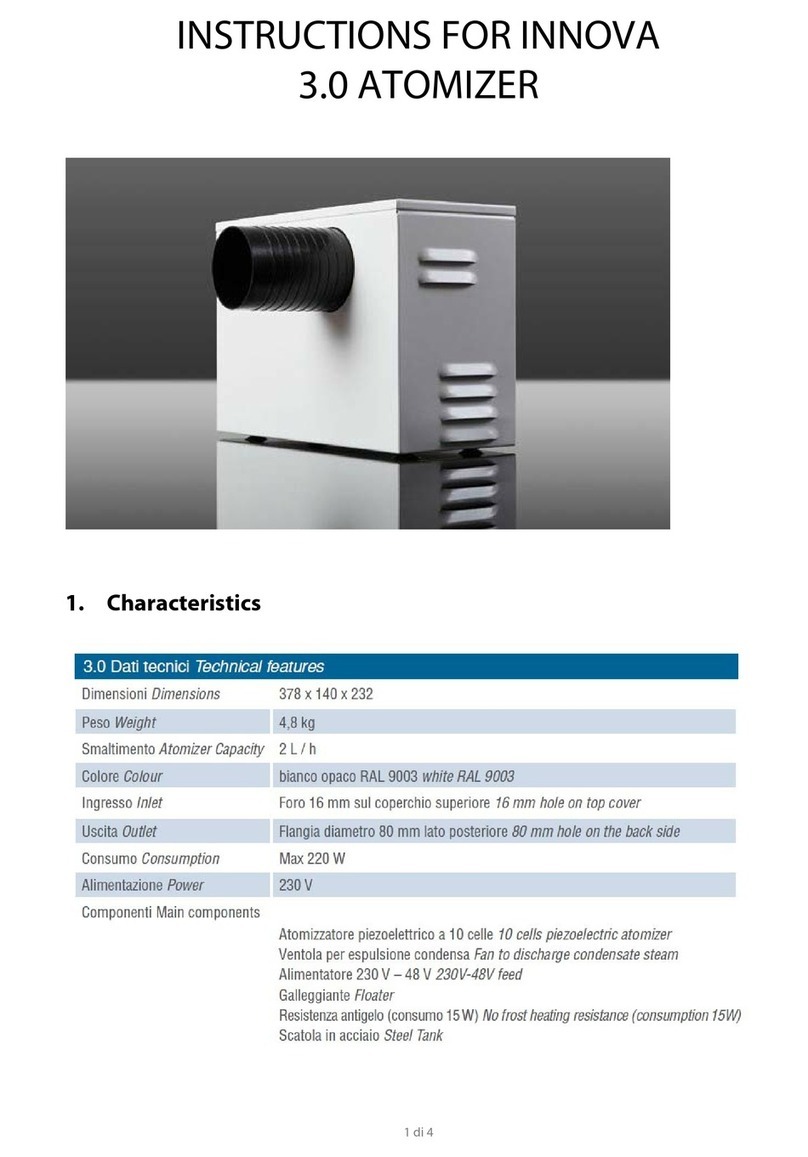

DESCRIPTION OF DESIGN AND OPERATION ................................................................................................................... 8

SYSTEMS DIAGRAM ............................................................................................................................................................... 9

INSTALLATION, CALIBRATION AND OPERATION.......................................................................................................... 10

MACHINE INSTALLATION ...................................................................................................................................................... 10

BATTERY POWER SOURCE .................................................................................................................................................. 10

For Stand Alone Operation-Not connected to vehicle charging system, recharging required .................................... 10

For Vehicle Mounted Operation - For continuous operation connected to vehicle charging system........................... 11

BATTERY CHARGING TIPS.................................................................................................................................................... 12

BATTERY VOLTMETER ......................................................................................................................................................... 13

PUMP CALIBRATION................................................................................................................................................................................... 14

FLOW RATE TABLE.............................................................................................................................................................. 14

OPTIONAL VARIABLE-FLOW-CONTROL ................................................................................................................................. 15

OPERATION ........................................................................................................................................................................ 16

DYNA-TRAX GPS OPTION................................................................................................................................................... 17

FLUSHING ............................................................................................................................................................................ 18

PREVENTATIVE MAINTENANCE SCHEDULE .................................................................................................................. 19

CLEANING THE ATOMIZER'S POROUS SLEEVE ............................................................................................................ 20

ELECTRICAL WIRING DIAGRAM (L30, SERIES 2)........................................................................................................... 21

TERMINAL STRIP WIRE CONNECTION DIAGRAM .......................................................................................................... 22

CONNECTING THE DYNA-JET L30 TO THE VEHICLE ELECTRICAL SYSTEM............................................................. 23

MAJOR COMPONENT DIAGRAM AND PARTS LISTING (L30) ....................................................................................... 24

ATOMIZER ASSEMBLY (L30) ................................................................................................................................................ 26

REMOTE CONTROL ASSEMBLY (L30).................................................................................................................................... 27

PUMP ENCLOSURE ASSEMBLY (L30).................................................................................................................................... 28

PUMP/BRACKET ASSEMBLY (L30)........................................................................................................................................ 30

BLOWER HOUSING ASSEMBLY (L30) .................................................................................................................................... 32

ACTUATOR ASSEMBLY......................................................................................................................................................... 34

FORMULATION TANK ASSEMBLY........................................................................................................................................... 35

FLUSH TANK ASSEMBLY ...................................................................................................................................................... 36

PLUMBING DIAGRAM (L30) .................................................................................................................................................. 37

FORMULATION FILTER ASSEMBLY (L30) ............................................................................................................................... 3 8

3-WAY VALVE ASSEMBLY .................................................................................................................................................... 3 9

2-WAY VALVE ASSEMBLY..................................................................................................................................................... 4 0

PUMP ENCLOSURE WIRING DIAGRAM (L30).......................................................................................................................... 41

REMOTE CONTROL BOX SCHEMATIC (L30, SERIES 2)........................................................................................................... 42

MAINTAINING THE L30 ATOMIZER ................................................................................................................................... 43

MACHINE MOUNTING DIAGRAM ...................................................................................................................................... 44

CONVERSION CHART ........................................................................................................................................................ 46