TABLE OF CONTENTS

NOTES.......................................................................................................................................................................................... 2

FOREWORD ................................................................................................................................................................................ 3

TABLE OF CONTENTS............................................................................................................................................................... 4

INDEX OF FIGURES.................................................................................................................................................................... 5

SECTION 1 | SAFETY .................................................................................................................................................................. 6

1.1 | SAFETY SYMBOLS.......................................................................................................................................................................... 6

1.2 | GENERAL RULES AND PRECAUTIONS .................................................................................................................................. 6

1.3 | SAFETY GUIDELINES.................................................................................................................................................................... 7

SECTION 2 | MAINTENANCE ................................................................................................................................................... 8

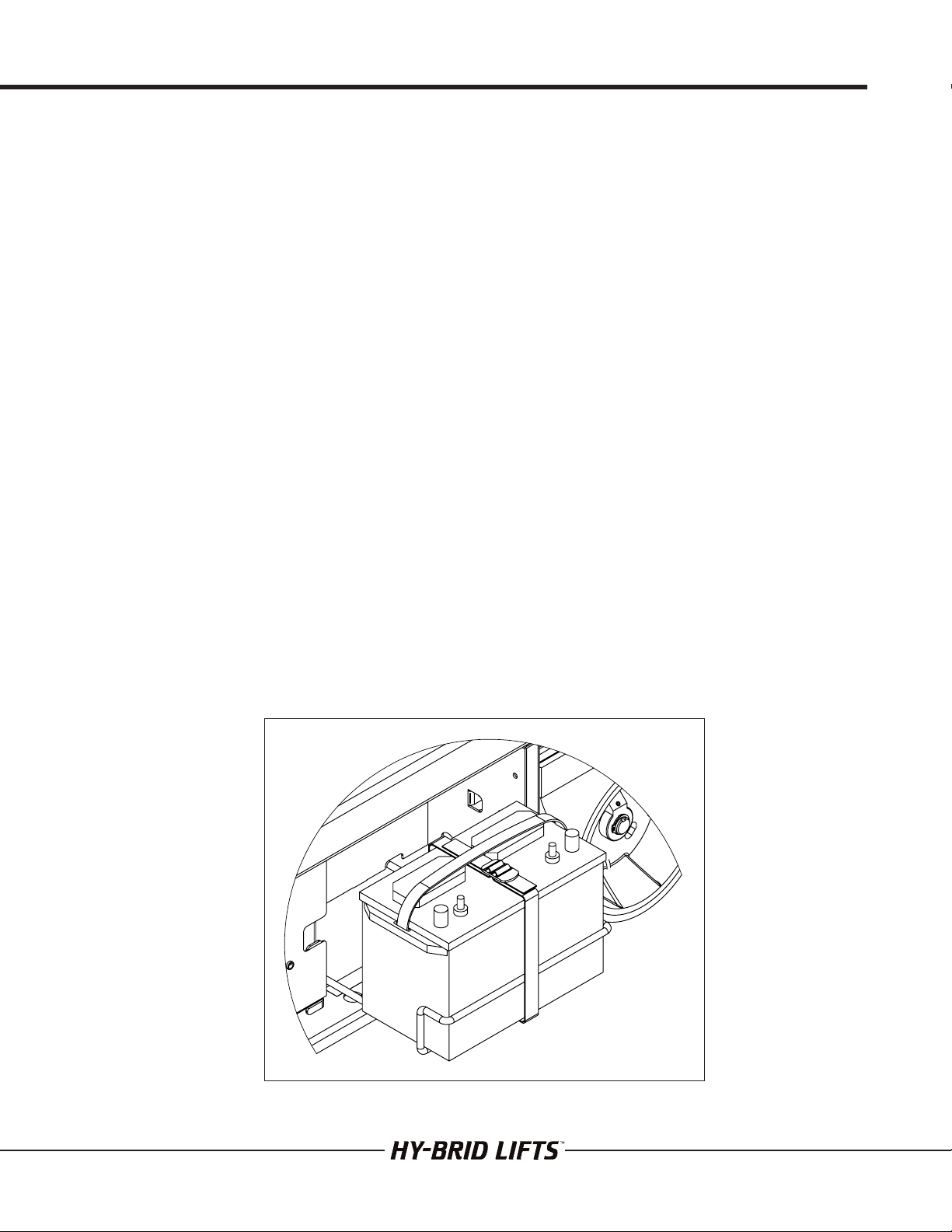

2.1 | BATTERY MAINTENANCE...........................................................................................................................................................8

2.2 | CHARGING THE BATTERY.........................................................................................................................................................8

2.3 | BATTERY MAINTENANCE AGM BATTERIES ........................................................................................................................ 10

2.4 | BATTERY MAINTENANCE WET CELL BATTERIES.............................................................................................................. 10

2.5 | LUBRICATION...............................................................................................................................................................................11

2.6 | COMPONENTS REQUIRING ADJUSTMENT .......................................................................................................................11

2.7 | EXAMINATION, REPAIR, REPLACEMENT OF LIMITED LIFE COMPONENTS ..............................................................11

2.8 | SAFETY DEVICES AND SYSTEMS REQUIRING CHECKS ..................................................................................................11

2.9 | STORAGE .....................................................................................................................................................................................11

2.10 | MAJOR ALTERATIONS OR REPAIRS.....................................................................................................................................11

SECTION 3 | MAINTENANCE CHECKLISTS ......................................................................................................................... 12

3.1 | PRESTART INSPECTION CHECKLIST................................................................................................................................... 14

3.2 | PREDELIVERY/ANNUAL/FREQUENT INSPECTION CHECKLIST.................................................................................. 15

SECTION 4 | TECHNICAL REFERENCES .............................................................................................................................. 16

4.1 | HYDRAULIC SCHEMATIC ......................................................................................................................................................... 16

4.2 | ELECTRICAL SCHEMATIC ....................................................................................................................................................... 18

4.3 | CONTROL BOARD DIAGNOSTIC..........................................................................................................................................20

SECTION 5 | WIRING DIAGRAMS.......................................................................................................................................... 22

5.1 | WIRING DIAGRAM .....................................................................................................................................................................22

5.2 | LWR CTL WIRING DIAGRAM ...................................................................................................................................................24

5.3 | UPPER CONTROLS WIRING DIAGRAM................................................................................................................................26

SECTION 6 | TROUBLESHOOTING FLOWCHARTS ...........................................................................................................28

6.1 | MAIN POWER/SAFETY CIRCUIT.............................................................................................................................................28

6.2 | DRIVE CIRCUIT...........................................................................................................................................................................30

6.3 | ELEVATE CIRCUIT ......................................................................................................................................................................32

6.4 | LOWER CIRCUIT.........................................................................................................................................................................34

6.5 | STEER CIRCUIT...........................................................................................................................................................................36

SECTION 7 | PARTS..................................................................................................................................................................38

SECTION 8 | WARRANTY........................................................................................................................................................40

SECTION 9 | INSPECTION AND REPAIR LOG .....................................................................................................................42

MAINTENANCE & TROUBLESHOOTING

PS-1030 | PS-1430

SUPO-742

REV A

4