Revised 11/4/2015

Coolant Flow Adjust

Air Flow Adjust

2

CustomCrimp® HS Models

The HS150 (1 HP) saw is capable of cutting up to 1-1/4 inch 4 wire hose and up to 1 inch 6 wire hose.

The HS300 (3 HP) saw is capable of cutting up to 1-1/4 inch 6 wire or 2 inch 2 wire hose.

The HS500 (5 HP) saw is capable of cutting up to 2 inch 6 wire hose with the serrated blade installed.

Installation

Mount the saw on a sturdy workbench.

The HS150 Hose Saw is only available in 110V single phase confi guration.

For the HS300 and HS500 Saws:

Make certain that the electric service is correct for the saw. The HS 300 and HS 500 saws are available in:

3 HP and 5 HP 220 Volt Single Phase

3 HP and 5 HP 220 Volt 3 Phase

3 HP and 5 HP 480 Volt 3 Phase

Check the blade rotation. The top of the blade should rotate towards the front of the saw. If

rotation is not correct on a 3 phase saw, reverse any two of the hot wires.

Always wear safety Glasses

Allow the blade to reach full speed before starting a cut

Periodically examine the blade for cracks and/or broken teeth.

Replace if necessary.

Do not remove or defeat any of the guards or safety features of the saw

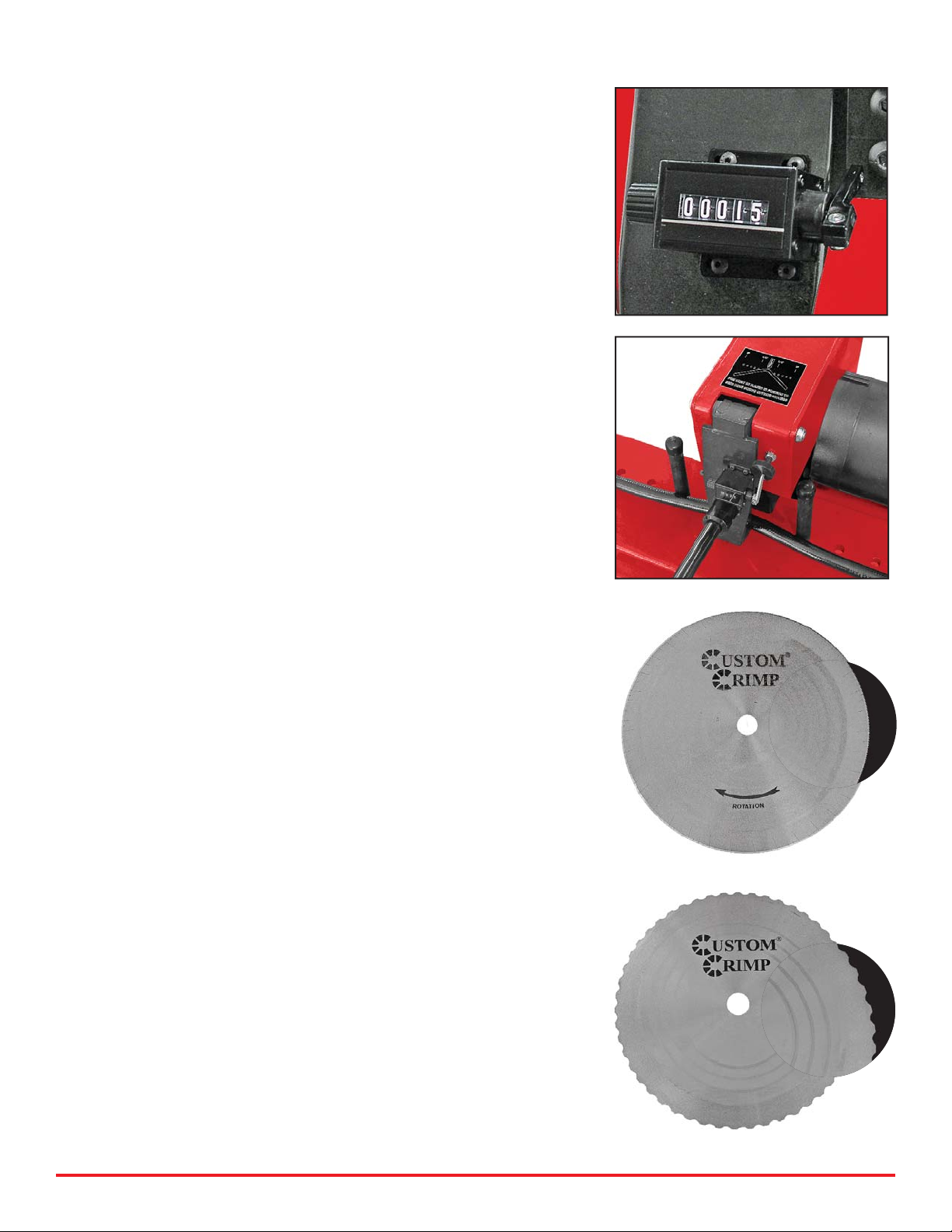

Mister Installation (Optional)

A Mister Kit (P/N 103172) is available for both the

HS 300 and HS 500 Hose Saws. The mister sprays a fi ne mist of

air tool oil on the saw blade for longer blade life and cleaner cuts.

Adjust the air pressure and fl ow control to spray a fi ne mist on the

blade. Addition of a mister kit will give smoother, cleaner cuts and

prolong blade life.

Refer to pages 5 and 6 for installation and setup of the Mister

Kit.

Hose Channel System (Optional)

A Hose Channel System (P/N 103073) is available in 5 foot sections

for the HS300 & HS500 models. The Hose Channel System both

measures and supports the hoses up to 2 inch diameter as they are

being cut.

Hose Helper (Standard on HS300 & HS500)

A “Hose Helper” attachment for the HS300& HS500 prevents the

hose from being drawn back during a cut and gives the operator the

ability to more precisely control the cut length. The “Hose Helper”

can be mounted on either end of the saw.