PHM-1A GAP CD WELD GUN MANUAL

COPYRIGHT CFI 2009 email: sales@cutlass-studwelding.com PAGE - 3 -

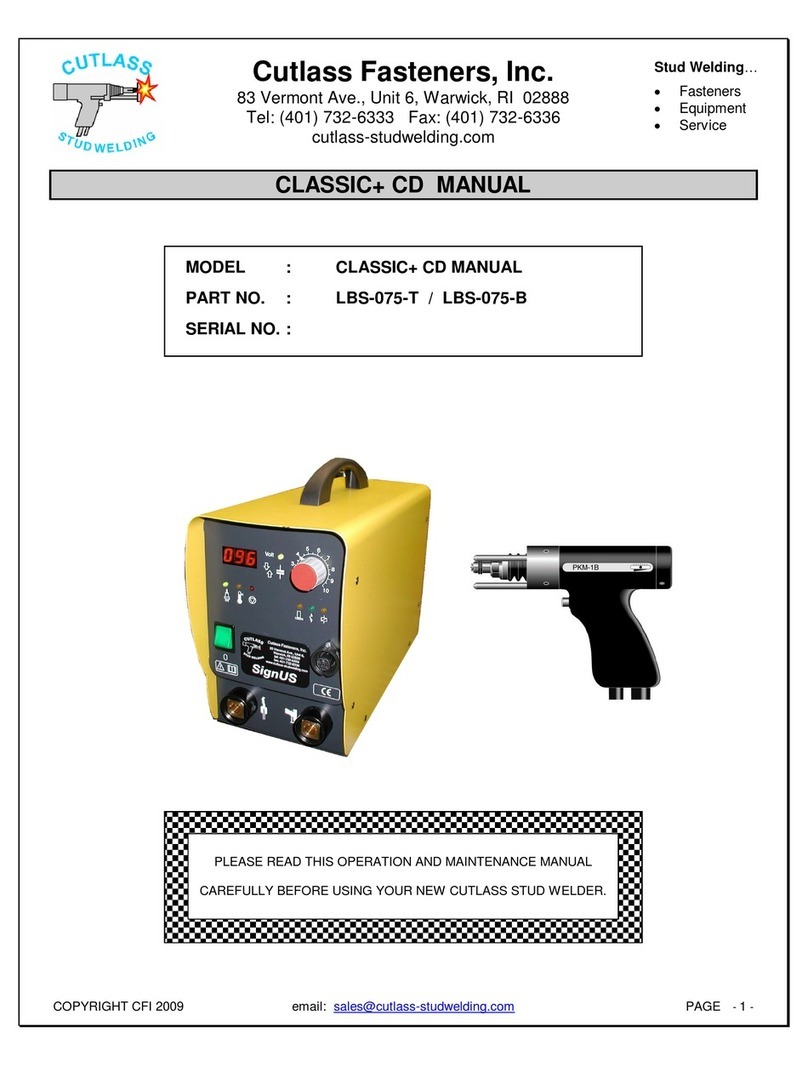

Cutlass Fasteners, Inc.

83 Vermont Ave., Unit 6, Warwick, RI 02888

Tel: (401) 732-6333 Fax: (401) 732-6336

cutlass-studwelding.com

Stud Welding…

Fasteners

Equipment

Service

SUGGESTED SAFETY PRECAUTIONS

In any welding operation, it is the responsibility of the welder to observe certain safety rules to insure his personal

safety and to protect those working near him.

Reference is directed without endorsement or recommendation, to ANSI Z49.1, Safety in Welding and Cutting,

and to AWG Publication A6, 1-66 Recommended Safe Practices for Gas-Shielded Arc Welding.

1. Always treat electricity with respect. Under open circuit conditions, the welding machine output may be

dangerous.

2. Do not work on live circuits and conductors. Disconnect the main power line before checking the machine or

performing any maintenance operations.

3. Ensure the welding machine cabinet is properly grounded to a good electrical ground.

4. Do not stand in water or on damp floors while welding or weld in the rain. Avoid wearing wet or sweaty

clothes when welding.

5. Do not operate with worn or poorly connected cables, and do not operate weld gun with loose cable

connections. Inspect all cables frequently for insulation failures, exposed wires, loose connections and repair

as needed.

6. Do not overload weld cables or continue to operate with hot cables.

7. Do not weld near flammable materials or liquids, in or near atmospheres, or on ducts carrying explosive

gases.

8. Do not weld on containers which have held combustible or flammable materials, or on materials which give

off flammable or toxic vapors when heated, without proper cleaning, purging, or inerting.

9. Ensure adequate ventilation is provided when welding in confined spaces.

10. Never look at the electrical arc without wearing eye shields.

11. Always use proper protective clothing, gloves etc. Never weld close to a bystander who is unaware of the

possible dangers of ultraviolet light and weld splatter on their eyes.

12. Installation, servicing and trouble shooting should only be done by qualified personnel, familiar with this type

of equipment.