3

Table of Contents

Machine Data Label. . . . . . . . . . . . . . . . . . . . . . . . . .2

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How To Use This Manual . . . . . . . . . . . . . . . . . . . . .4

Safety

Important Safety Instructions . . . . . . . . . . . . . . . . . .5

Hazard Intensity Level . . . . . . . . . . . . . . . . . . . . . . .6

Safety Label Location . . . . . . . . . . . . . . . . . . . . . . . .7

Operations

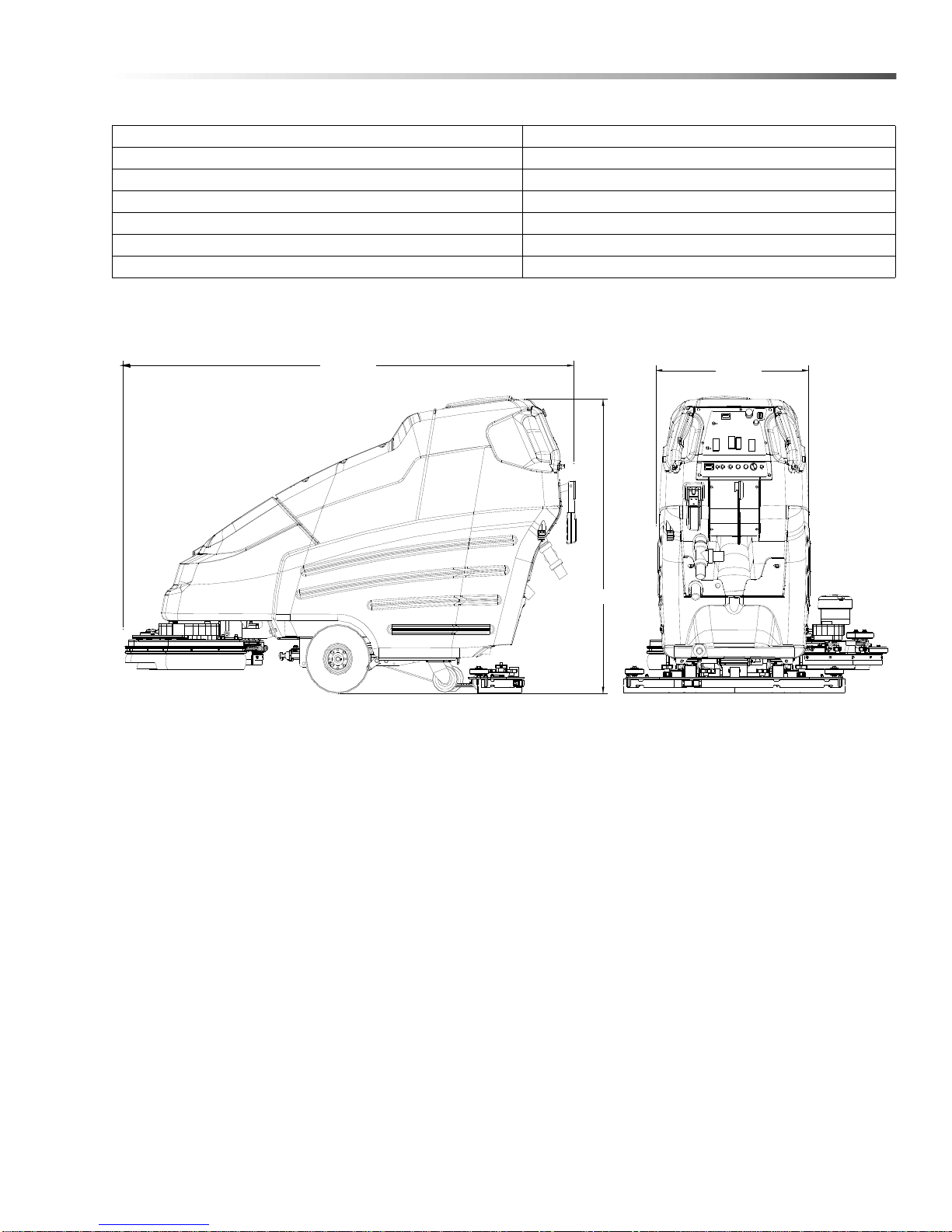

Technical Specifications . . . . . . . . . . . . . . . . . . . . . .8

How The Machine Works . . . . . . . . . . . . . . . . . . . .10

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . .16

Pre-Run Machine Inspection. . . . . . . . . . . . . . . . . .16

Starting Machine. . . . . . . . . . . . . . . . . . . . . . . . . . .16

Emergency Stop Procedures . . . . . . . . . . . . . . . . .16

Filling Solution Tank . . . . . . . . . . . . . . . . . . . . . . . .16

Normal Scrubbing. . . . . . . . . . . . . . . . . . . . . . . . . .17

Emptying And Cleaning Tanks . . . . . . . . . . . . . . . .18

Solution Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Recovery Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Maintenance

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . .19

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Checking Battery Specific Gravity. . . . . . . . . . . . . .22

To Charge the Batteries . . . . . . . . . . . . . . . . . . . . .22

Changing Batteries . . . . . . . . . . . . . . . . . . . . . . . . .23

Battery Connections . . . . . . . . . . . . . . . . . . . . . . . .23

Rear Squeegee. . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Adjusting Squeegee . . . . . . . . . . . . . . . . . . . . . . . .24

To Remove Squeegee Assembly . . . . . . . . . . . . . .24

To Adjust Squeegee Pitch . . . . . . . . . . . . . . . . . . .25

To Adjust Amount of Rear Squeegee Deflection . .25

Scrub Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Recovery Tank Float Shut-Off . . . . . . . . . . . . . . . .26

Solution Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Brush Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Traction Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Brush Shroud & Brush Skirts . . . . . . . . . . . . . . . . .28

Vacuum Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Actuator Scrub Deck Up-Down Removal/

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Front Side Squeegee . . . . . . . . . . . . . . . . . . . . . . .31

Adjusting Squeegee . . . . . . . . . . . . . . . . . . . . . . . .31

To Remove Squeegee Assembly . . . . . . . . . . . . . .31

To Replace Or Rotate Front Side Squeegee Blade31

To Adjust Front Side Squeegee Deflection. . . . . . .32

Axle - Recommended Greasing . . . . . . . . . . . . . . .33

Machine Troubleshooting . . . . . . . . . . . . . . . . . . . .34

Parts

Control Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cover (Front) & Tank Mount . . . . . . . . . . . . . . . . . 40

Cover (Top) & Tank Mount . . . . . . . . . . . . . . . . . . 42

Decal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Electrical Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Lift Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Lift Handle Linkage . . . . . . . . . . . . . . . . . . . . . . . . 50

Recovery Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Scrub Brush/Pad Driver . . . . . . . . . . . . . . . . . . . . 54

Scrub Deck Motors . . . . . . . . . . . . . . . . . . . . . . . . 56

Scrubdeck Right Frame . . . . . . . . . . . . . . . . . . . . 58

Scrubdeck Left Frame. . . . . . . . . . . . . . . . . . . . . . 60

Scrubdeck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Scrubdeck Linkage 1 . . . . . . . . . . . . . . . . . . . . . . 64

Scrubdeck Linkage 2 . . . . . . . . . . . . . . . . . . . . . . 66

Scrubdeck Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Solution 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Solution 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Solution Hose Asm . . . . . . . . . . . . . . . . . . . . . . . . 74

Squeegee - Front Side . . . . . . . . . . . . . . . . . . . . . 76

Squeegee-Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Squeegee Lift Linkage (Lower). . . . . . . . . . . . . . . 80

Front Squeegee Linkage. . . . . . . . . . . . . . . . . . . . 82

Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Wheels And Frame . . . . . . . . . . . . . . . . . . . . . . . . 86

Wiring-Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Wiring-Control Panel. . . . . . . . . . . . . . . . . . . . . . . 90

Wiring-Main Harness . . . . . . . . . . . . . . . . . . . . . . 92

Wiring-Schematic . . . . . . . . . . . . . . . . . . . . . . . . . 94

Options

Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Suggested Spare Parts. . . . . . . . . . . . . . . . . . . . 100

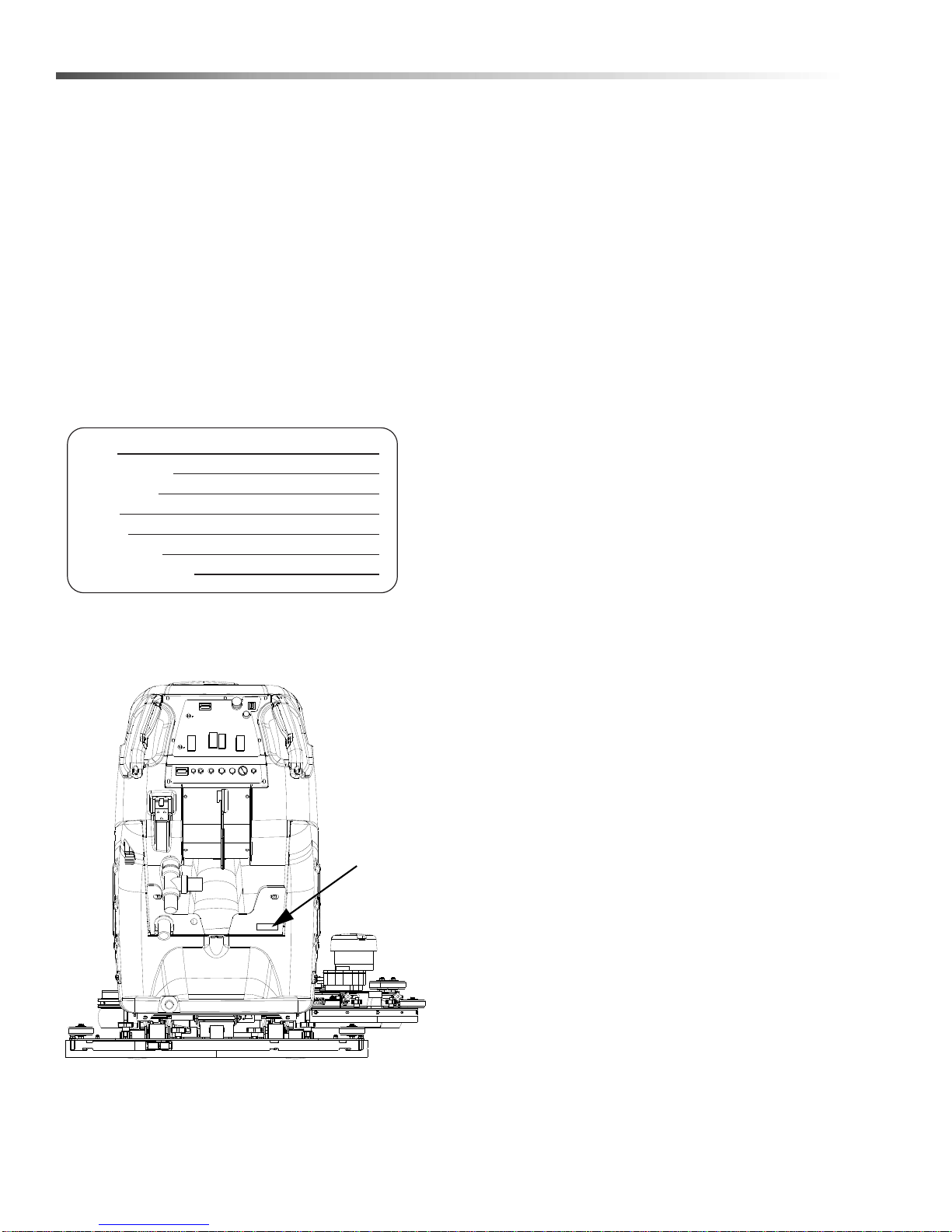

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 101

86037150 SCX364