General Hazar

d

s

All moving parts of the refrigerator are suitably guarded any repairs and

maintenance should only be carried out by a qualified professional

Electrical C

onn

ec

tion

This cabinet is supplied with a flexible power cable that has a molded

3 pin plug on the end. The plug needs to be accessible once the

equipment is placed in its final position. Do not overload the power

supply (see rating label inside cabinet for power supply and current

draw) should the plug require replacement please contact a qualified

electrician.

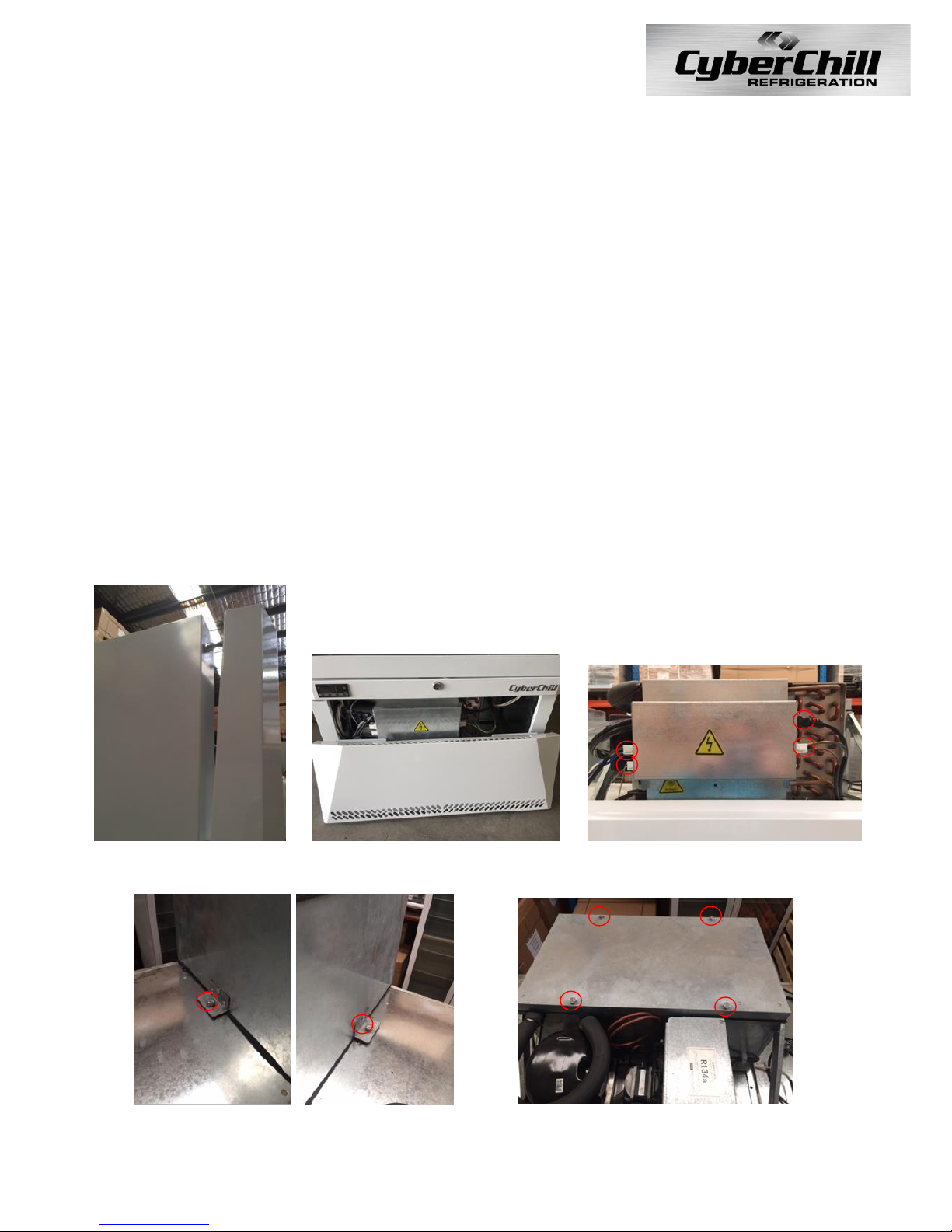

Unpacking

Leave all packaging in place until refrigerator is in its final position to avoid

damage. When the cabinet is in its final position, carefully remove all packaging

and check for damage. Any damage should be reported immediately to your

dealer. All packaging should be carefully disposed of and recycled where

possible.

In

sta

ll

a

tion

The cabinet is very easy to move around as it’s supplied on castors. If for any

reason the cabinet has to be laid down, it should always be laid on its back

and not its side or front to avoid damage. When lowering or raising the

cabinet extreme care should be taken as the casters can cause the

cabinet to slip away whilst lifting or lowering. A person should always

be standing at the base of the cabinet whilst it is being lowered or

raised. Cabinet should not be plugged in for at least 1 hour if it has

been laid down or tipped during installation.

This product must be placed on a level floor to ensure the automatic

door closing and correct draining of condensate. Once in final position

lock the two front castors by pushing down on the extended tab.

V

e

ntil

a

tion

For efficient operation of the cabinet, it is essential that adequate ventilation be provided

around the refrigeration unit. The maximum recommended ambient temperature (at

place of installation) is 43°C, although the cabinet will generally use less power when

installed in a cooler location. Refrigeration equipment generates a lot of heat. Therefore,

it is very important that the cabinet must be installed with sufficient space around it for

ventilation and for maintenance access. Ventilation grills must not be blocked, or even

partially blocked as this could affect the cabinet’s performance and life span.