ROBOT . HEAD to TOE

Product User’s Manual – Shock Sensor

Created by Cytron Technologies Sdn. Bhd. – All Rights Reserved 4

Bc547

Q2

BC557

Q1

2N2222

Q3

10K

R1

10K

R3

1K

R4

220

R6

10K

R5

1K

R7

Buzze r

VCC

1K

R2

Reset Button

S1

1

2

3

Header 3H

Connector to ShockSensor

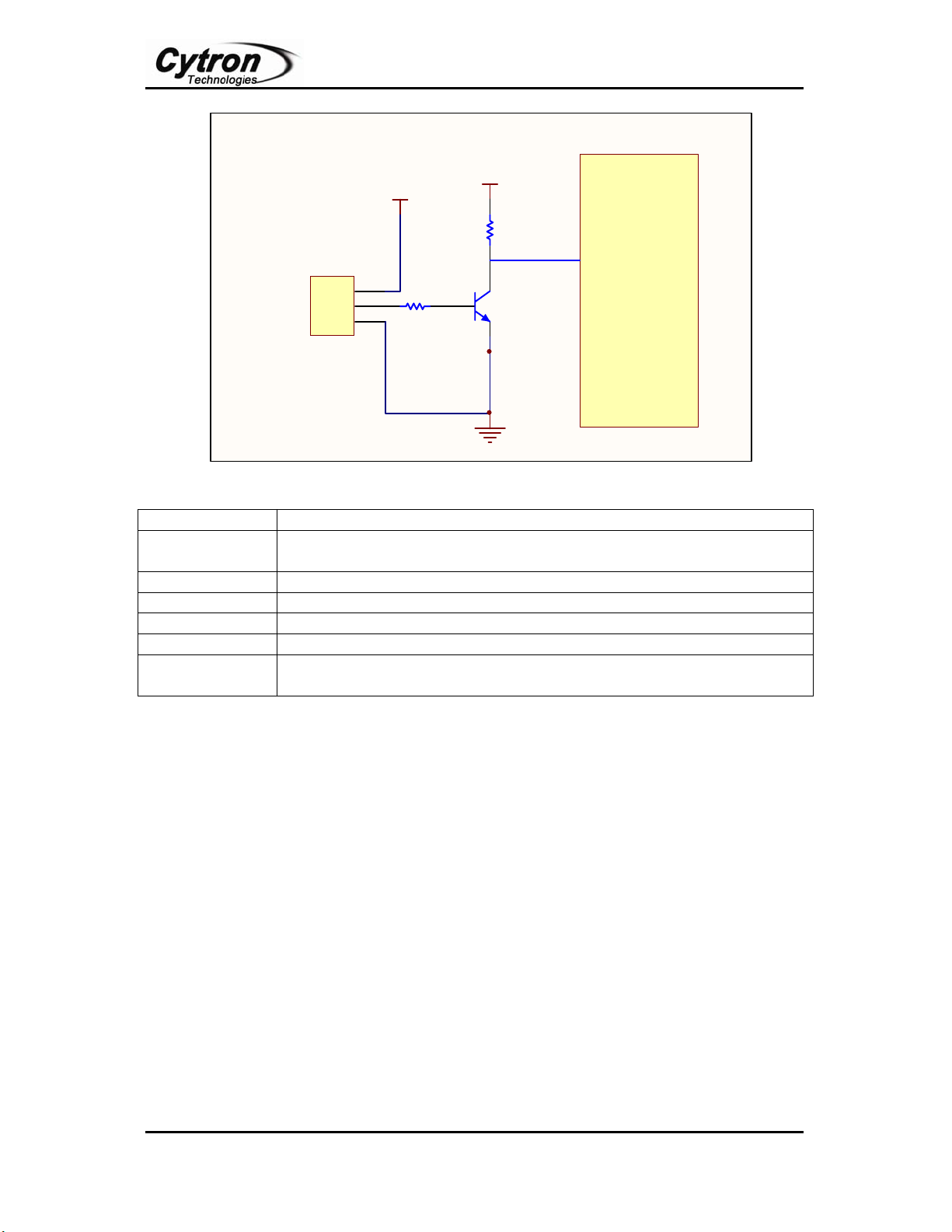

4. GETTING STARTED

4.1 Connecting and Testing

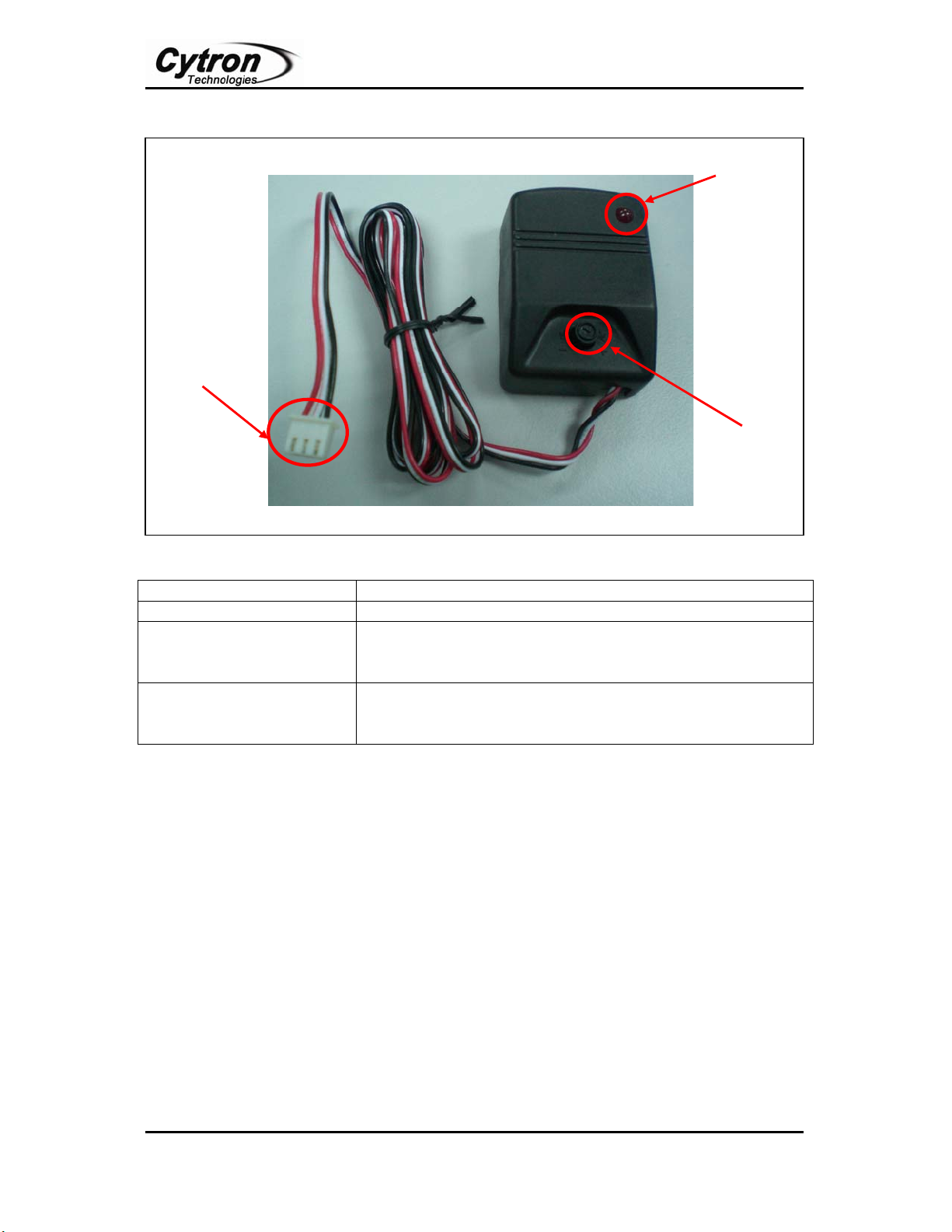

Connect the 3-pin header to your circuit so that the black colour pin connects to ground, the

red color pin connects to Vcc and the white colour pin connects to your output signal pin. The

unit output is LOW whenever there is shock detected. The output voltage of shock sensor

followed the voltage supplied to the sensor (Vcc) when there is no shock detected. Please

refer schematic in Figure 4.1 and Figure 4.2 for example application.

Figure 4.1: Example application for Shock Sensor (Without microcontroller).

Part Description

Header 3H Connects to Shock Sensor, pin 1 to GND (Black color), pin 2 to output

(White color) and pin 3 to Vcc (Red color).

Vcc Connects to Vcc (+5V to + 12V)

Buzzer Connects to buzzer (+5V to + 12V)

S1 Reset button for the circuit.

R1, R3, R5 10kΩResistor

R2, R4, R7 1kΩResistor

R6 220ΩResistor

Q1 PNP transistor ( BC557)

Q2 NPN transistor ( BC547)

Q3 NPN transistor ( 2N2222)

Table 4.1

With reference to Figure 4.1, the buzzer will be ON when there is a shock detected, and the

buzzer will only OFF when the reset button being press. The buzzer is chosen depends on the

value of Vcc. 5V buzzer will be choose when Vcc is connect to 5V whereas 12V buzzer is

chosen when Vcc is connected to 12V.