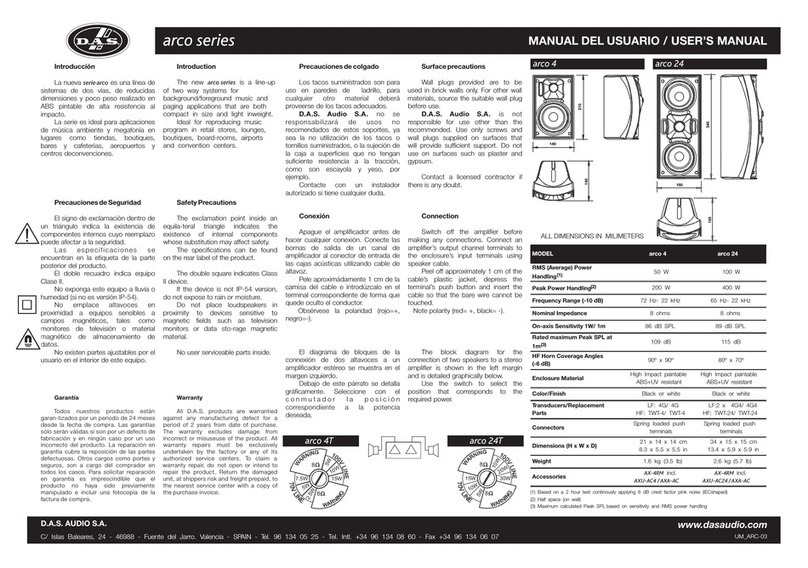

D.A.S. AERO-38 series User manual

Manual del Usuario / User’s Guide

AERO-38 series

®AERO-38A / AERO-38

AERO-218A / AERO-218Sub

AERO-182A / AERO-182

D.A.S. Audio s.a.

El signo de exclamación dentro de un triángulo indica la

existencia de componentes internos cuyo reemplazo puede

afectar a la seguridad. También indica instrucciones importantes

defuncionamientoymantenimiento.

El signo del rayo con la punta de flecha alerta contra la presencia

de voltajes peligrosos no aislados. Para reducir el riesgo de

choqueeléctrico,noretirelacubierta.

Conserve estas instrucciones. Siga todas las advertencias. Lea

todas las instrucciones.

Aparato de Clase I. [AERO-38A, AERO-218A, AERO-182A]

Para una protección continua contra el riesgo de fuego,

reemplace el fusible únicamente con otro del mismo tipo, que se

indicaenlacubiertadelaunidad.

Para reducir el riesgo de descarga eléctrica no exponga este

equipo a la lluvia, humedad o salpicaduras sin el protector de

lluviasuministradoporelfabricante.

No instale el sistema cerca del agua, piscinas y fuentes por

ejemplo.Nodepositesobreélrecipientesquecontenganlíquidos.

Limpie el aparato sólo con un paño seco. No use limpiadores

basadosendisolventes.

No instale el aparato cerca de ninguna fuente de calor como

radiadores,estufasuotrosaparatosqueproduzcancalor.

El cable de alimentación suministrado con su unidad tiene

conector de tres terminales (tipo X). No corte o dañe el terminal

de tierra. Si el conector suministrado no puede conectarse en su

enchufe, consulte a un electricista para sustituir el enchufe

obsoleto. Proteja el cable de alimentación de ser pisado o

pellizcado.

Desconecte este aparato durante tormentas eléctricas, lluvia

torrencial, terremotos o cuando no se vaya a emplear durante

largosperiodos.

No existen partes ajustables por el usuario en el interior de este

equipo. Cualquier operación de mantenimiento o reparación debe

ser realizada por personal cualificado. Es necesario el servicio

técnico cuando el aparado se haya dañado de alguna forma, tal

como que el cable de corriente o el enchufe se hayan dañado,

haya caído líquido o algún objeto en el interior del aparato, el

aparato haya sido expuesto a lluvia o humedad, no funcione

correctamenteohayarecibidoungolpe.

El colgado de la caja sólo debe realizarse utilizando los herrajes de

colgado y solamente por personal cualificado. No cuelgue la caja

delasasas.Noreemplacepasadoresdeseguridadportornillos.

Precauciones de seguridad Safety Precautions

The exclamation point inside an equilateral triangle indicates the

existence of internal components whose substitution may affect

safety.Alsoindicatesimportantoperatinginstructions.

The lightning and arrowhead symbol warns about the presence of

uninsulated dangerous voltage. To reduce the risk of electric

shock,donotremovethecover.

Keep these instructions. Heed all warnings. Follow all

instructions.

ClassIdevice.[AERO-38A,AERO-218A,AERO-182A]

For continued protection against risk of electric fire replace fuse

only with same type fuse, which is indicated on the cover of the

unit.

Do not expose this device to rain, moisture or splash without

usingtherainprotectorsuppliedbyDAS.

Do not use this apparatus near water- for example, swimming

pool, fountain. Do not place any object containing liquids as

bottlesonthetopoftheunit.

Clean only with a dry cloth. Do not use any solvent based

cleaners.

Do not install near any heat sources such as radiators, heat

registers,stoves,orotherapparatusthatproduceheat.

The power cord supplied with your unit has a 3-pin type plug (X

type). Do not cut off or damage the grounding pin. If the provided

plug does not fit in your outlet, consult an electrician for

replacement of the obsolete outlet. Protect the power cord from

beingwalkedonorpinched.

Unplug this apparatus during lightning storms, heavy rain,

earthquakesorwhenunusedforlongperiodsoftime.

No user serviceable parts inside. Refer all servicing to qualified

service personnel. Servicing is required when the apparatus has

been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled or objects have fallen into the

apparatus, the apparatus has been exposed to rain or moisture,

doesnotoperatenormally,orhasbeendropped.

The appliance should be flown only from the rigging points and by

qualified personnel. Do not suspend the box from the handles. Do

not use instead of quick release pins any other element as

fasteners.

Nuncacuelguemáscajasdelasrecomendadasporelfabricante. Never exceed the maximum number of units to be flown

recommendedbythemanufacturer.

El doble cuadrado indica equipo de Clase 2 en sistemas de

amplificaciónexterna:AERO-38, AERO-218SubyAERO-182.

The double square indicates Class 2 device; models : AERO-38,

AERO-218Sub and AERO-182.

224

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

36

236

220 256

823

36

1010

680

AERO-218Sub

ALL DIMENSIONS IN MILIMETERS

1. SYSTEM DESCRIPTION

The D.A.S. Audio AERO series offers two

units for applications requiring precise control of the

vertical coverage and high sound pressure levels. The

AERO-38 is an externally powered, three-way, high

efficiency line array module which integrates two 12”

low frequency units with 4” voice coils, two 10” mid-

range devices which utilize 3” voice coils and one

compression driver with 4” coil and 1.5” exit

geometry in a single unit. The compression driver is

coupled to the Serpis-38 high frequency plane wave

adaptor insuring coherent high frequency summing

and the generation of a flat, isophasic wave front.

When increased sound pressure level in the low

frequency range is required, the system can be used

in conjunction with the AERO-218Sub

subwoofer units. There are self powered version of

eachcabinet,AERO-38A,AERO-218A,AERO-182A.

The system is ideal for applications such as

large-scale outdoor/indoor events in arenas, stadiums

or theaters. Use of the DSP-3VS digital processor is

recommended for the AERO-38 and the DS

The loudspeakers used in the system

feature advanced technologies; new TAF (

cooling systems, Neodymium magnetic circuits

which allow for important weight reductions, titanium

diaphragms for the high frequency sections, and low-

mid frequency cones manufactured using crossed

fibers and elastic suspension that provide exceptional

stabilityintheverticalplane.

or AERO-182

DSP-3VS digital processor with the

AERO-38 will adversely affect the sound quality and

maydamagesystemcomponents.

total air

flow)

P-1Sub

Both units are manufactured using 15/18

mm Finnish Birch plywood. The AERO-38 enclosure

shape is trapezoidal with 5º angles. The AERO-

218 enclosures are rectangular.

The Aero-38 and AERO-182 systems incorporate

captive rigging hardware which is compatible with

one another and designed to provide a fast, simple

and safe rigging by means of quick release safety

pins. Splay angles can be changed from 0º to 3.2º in

0.8º increments and from 3.2º to 9.6º in 1.6º

increments.

To facilitate transport, the AERO-38 units are

equipped with a PL-38 front dolly panel attached by

means of the rigging hardware. The front dolly panel is

useful when rigging systems. The PL-48S, a metal

dolly for vertically stacking 3 to 4 AERO-38 units is

available as an accessory. The AERO-218 units

can be moved by way of the four rear located casters.

Also the AERO-182 system incorporates a PL-48 dolly

panelusefulltotransportthecabinet.

for

the subwoofer system (AERO-218Sub or AERO-182).

Not using the

Sub and AERO-182

Sub

The model AERO-38 includes two 12GNC

12” cone transducer with 4” EFW voice coils and

Neodymium magnet assemblies in a bass-reflex

configuration. Two 10LMN16, 10” speakers arranged

in a V shape, incorporating 3” EFW voice coils,

Neodymium magnet assemblies and TAF cooling

system are used for mid-range reproduction. High

frequencies are handled by one ND-10 high frequency

compression driver with 4” EFW coil, Neodymium

magnet and 1.5” exit coupled to one SERPIS-38 plane

wave guide. The SERPIS-38 plane wave adaptor also

serves as a heat sink for the compression driver. The

AERO-218 include two 18GN 18”

cone transducers with 4” EFW voice coils and

Neodymium magnets. These cabinets are intended

for applications when extending the frequency range

ofthesystemisrequired.

Sub and AERO-182

Aero-38 Manual del usuario/ User´s manual 43

1380

316

595

AERO-38

ALL DIMENSIONS IN MILIMETERS

1400

475

580

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

WARNING!DONOTSUSPEND FROM THIS HANDLE

¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA¡ATENCIÓN!NOCUELGUELA CAJA DE ESTE ASA

AERO-182

ALL DIMENSIONS IN MILIMETERS

2. RIGGING SYSTEM

2.1WARNING

Thismanualcontainsneededinformationfor

flying D.A.S. Audio line array systems, description of

the elements and safety precautions. To perform any

operations related to flying the system, read the

present document first, and act on the warnings and

advice given. The goal is to the allow the user to

become familiar with the mechanical elements

required to fly the acoustic system, as well as the

safety measures to be taken during set-up and

teardown.

Only experienced installers with adequate

knowledge of the equipment and local safety

regulations should fly speaker boxes. It is the user's

responsibility to ensure that the systems to be flown

(including flying accessories) comply with state and

localregulations.

The working load limits in this manual are

the results of tests by independent laboratories. It is

the user's responsibility to stay within safe limits. It is

the user's responsibility to follow and comply with

safety factors, resistance values, periodical

supervisions and warnings given in this manual.

Product improvement by means of research and

development is on going at D.A.S. Specifications are

subjecttochangewithoutnotice.

To this date, there is no international

standard regarding the flying of acoustic systems.

However, it is common practice to apply 5:1 safety

factors for enclosures and static elements. For slings

and elements exposed to material fatigue due to

friction and load variation the following ratios must be

met; 5:1 for steel cable slings, 4:1 for steel chain

slings and 7:1 polyester slings. Thus, an element with

a breaking load limit of 1000 kg may be statically

loaded with 200 kg (5:1 safety factor) and

dynamicallyloadedwith142Kg(7:1safetyfactor).

When flying a system, the working load

must be lower than the resistance of each individual

flying point in the enclosure, as well as each box.

Hanging hardware should be regularly inspected and

suspect units replaced if in doubt. This is important to

avoid injury and absolutely no risks should be taken in

this respect. It is highly recommended that you

implement an inspection and maintenance program

on flying elements, including reports to be filled out by

the personnel that will carry out the inspections. Local

regulations may exist that, in case of accident, may

require you to present evidence of inspection reports

andcorrectiveactionsafterdefectswerefound.

Absolutely no risks should be taken with

regards to public safety. When flying enclosures from

ceiling support structures, extreme care should be

taken to assure the load bearing capabilities of the

structures so that the installation is absolutely safe.

Do not fly enclosures from unsafe structures. Consult

a certified professional if needed. All flying

accessories that are not supplied by D.A.S. Audio are

theuser'sresponsibility.Useatyourownrisk.

D.A.S. Audio AERO-38 and AERO-182 line

array systems, include 2 rigging structures on each

side of the box. Manufactured from zinc plated steel

they are painted black and are affixed to an internal

plate with special crop resistant screws. Two special

stainless steel guides are assembled to each of the

structures: G1A48 (front guide) and G2A48 (back

guide), allow for stacking or flying of boxes.

To lock both guides, six (6) quick release safety pins

(supplied)mustbeused.

The G1A48 front guide provides a solid

connection to the box and whatever is on top of it,

while the G2A48 rear guide determines the vertical

splay angle (whether stacked or flown), as a function

oftheholewherethepingetsinserted.

2.2 DESCRIPTION/ACCESSORIES

Splay

angles can be changed from 0º to 3.2º in 0.8º

increments and from 3.2º to 9.6º in 1.6º increments.

Aero-38 Manual del usuario/ User´s manual 44

G2A48

G1A48

QUICK RELEASE PIN 8X30

(6 UNITS PER CABINET)

To aid the setting of the G2A48 guide in the

corresponding hole in the top box, each hole is labeled

with an associated angle, both for stacked and flown

applications. To fit the guides into the holes, highly

resistant 8 mm quick release pins with a ball safety

lock areused.

4.8º

6.4º

8º

9.6º

3.2º

1.6º

0º

0.8º

STACK

4.8º

6.4º

8º

9.6º

3.2º

1.6º

0º

0.8º

2.4º

FLY

Splay angles

STACK FLY

For flying boxes and defining the splay

angle, the pins must be inserted in the of guide 2,

G2A48, whereas for stacking ( ), the pin goes

throughthe oftheguide.

slot

top hole

stacked

All of the elements needed to rig or stack the

systems are integral to the enclosure (

and the quick release safety pins). The additional

items needed are the AX-AERO48 or AX-AERO38

flying grids (bumper bars), chains and hoists, the PL-

38 or PL-48S dolly platforms and the AX-COMBO

G1A48, G2A48

A) AX-AERO48 and AX-AERO38

The AX-AERO48 grid is made from 100 x 50

x 6mm steel beams and is designed to handle great

loads. It features a center reinforcement bar that is

also used for the lifting slings. The force of both the

rear and the front chain hoist will determine the tilt

angle of the whole array. The structure will be

attachedtothefirstenclosure of the array by means of

the guides G1A48, G2A48, and six quick release

safetypins.

Weight

Dimensions: 144x93x10 cm

(HxWxD)

: 75Kg (165 lbs)

57x36.6x4 in

Pickup points

Aero-38 Manual del usuario/ User´s manual 45

The AX-AERO38 grid is lighter than the other one, and

it is recommended to be used to fly a maximum of 8

cabinetsAERO-38A or 6 AERO-48.

Weight

Dimensions: 147x62x10 cm

(AlxAnxP)

: 60Kg (132 lbs)

57.8x24.4x4 in

For example, if 12 units AERO-48 are going

to be flown from the AX-AERO48, each hoist to be

usedshouldhavealoadcapacityof2ton.

>750Kg

>750Kg

>750Kg

1 6units-->

1 6units-->

1 8units-->

AERO-48

AERO

182

AERO-38

AX-AERO38

AX-AERO48

>1000Kg

>1000Kg

>750Kg

>2000Kg

>2000Kg

>1500Kg

1 8units-->

1 8units-->

1 10units-->

9 16units-->

9 16units-->

11 20units-->

AERO-48

AERO

182

AERO-38

Load capacity per hoist (safety factor 10:1)

B) Chain hoists

All units in a column will be flown from the

AX-AERO48 (AX-AERO38) flying grid (bumper bar),

which should be used with two hoists, one located in

the front and the other in the rear. Each hoist should

have a minimum of 1 Ton load capacity when flying up

8 units and a 2 Ton load capacity when flying 9 to 16

units.

C) Platforms PL-48 and PL-38

The PL-38 dolly panels facilitate transport of

the AERO-38 systems. They can also be used to

facilitate flying the systems. Each cover is attached to

the enclosure by using the flying hardware attached

to each box and is fixed with the quick release safety

pins. The AERO-182 systems also include one PL-48

dollypanelpercabinet.

AERO-182

PL-48

AERO-38

PL-38

D) PL-48S

The PL-48S platform is a valuable accessory

which allows up to 4 AERO-38 units to be transported

in a stacked position, ready to be flown. The PL-48S is

made from steel and has 4 heavy duty casters with

lockingbrakes.

Aero-38 Manual del usuario/ User´s manual 46

PL-48S

AX-COMBO

AERO-38

AERO-28

AX-AERO48

E) AX-COMBO

The AX-COMBO is a rigging adapter to be

used when Aero-28 units are needed to be flown

under AERO-38 units as dowfill systems. Maximum 6

CA-28A units and 8 CA-28/CA-28B units can be flown

from this rigging grid. The AX-COMBO includes front

and rear steel guides which permit variation of the

angle between it and the last AERO-38 cabinet in the

cluster. Angles vary from 0.0º to 9.6º.

AX-COMBO

G2A48

G1A48

G2A48

Weight

Dimensions: 143x60x5cm (56.3x23.6x2in)

: 16.5Kg (36.3 lbs)

G1A48

The AX-COMBO is joined to the last AERO-

38 cabinet using G1A48 and G2A48 included steel

guides and 6 quick release pins. The angle depends on

the hole of the rigging structures where the pins are

inserted, through the slots of G2A48. The first AERO-

28 unit is joined to the AX-COMBO using its G1A and

G2Aincludedcamlinks.

On the next page is a table with the angles between

both systems depending on the hole where the quick

releasepinisbeinginserted.

SPLAY ANGLES USING THE AX-COMBO

F) QUICK RELEASE PINS

Each cabinet includes 6 steel heavy duty

quick release pins stored on the rear panel of the

cabinets.

Both systems AERO-38, and AERO-182 can

be flown using steel structures located on boths sides

of the cabinets. NEVER REPLACE QUICK RELEASE

PINSWITHSCREWSOROTHERELEMENTS!!!

Pins can be used to

free the pieces

G1A48, G2A48.

Pins

Aero-38 Manual del usuario/ User´s manual 47

2.3 SAFETY FACTORS

breaking load limit and the

maximum safe working load limit (SWLL). In this

case, the breaking load limit of each of the flying

points is 4,000 kg (8,820 lbs) as determined by

destructive testing in independent laboratories. With

a 10:1 safety factor, a total amount of 1,600 kg (3,527

lbs) can be flown from the 4 flying points. Each flying

point has a capacity of 400 kg (882 lbs) with a 10:1

safetyfactor.

The safety factor is defined as the

coefficient between the

T

Theuseof two hoists with a load capacity as

expressed on the previous page is mandatory. It

should be kept in mind that at certain moments, the

complete load may be supported by only one of the

hoists.

he maximum number of AERO-38 units

that can be suspended from the AX-AERO48 flying

grid is 20 (with 10:1 safety factor). T

The

maximum limits established by the manufacturer

shouldneverbeexceeded.

This is why the load capacity of the individual

hoist must be superior to the weight of the array

column.

NOTE: The rigging systems of the AERO-38 and the

AERO-48 are compatible. Some accessories (AX-

AERO38,AX-AERO48)canbeusedbybothsystems.

he maximum

number of AERO-182 units that can be suspended

from the AX-AERO48 flying grid is 16 (10:1).

Aero-38 Manual del usuario/ User´s manual 48

4 x 400Kg (10:1)

3.1 AERO-38A

3. SELF-POWERED SYSTEMS

The Aero-38A is a three way, class D, self

powered system.

Nominal amplifier power (RMS) per way:

LF:1000W MF: 500W HF:500W

Amplifierpaneldescription:

A) : A

B) :

C) :

E) .

F1) :

F2) :

6 (at 230V)

G) :

1=GND(ground)

2=(+)Noninvertedinput

3=(-)Invertedinput

H) :

LIMIT

SIGNAL

ON

FUSE

AC INPUT

AC OUTPUT

INPUT

LOOP THRU

D) : Indicates that the amplifier

is under protection mode because damage risk due to

shortcircuitorextremeworkingtemperature.

PROTECTION

mplifier limiter indicator lights.

When lit, the level of the signal source should be

reduced.

Signal presence indicator at the

amplifiers'inputs.

Indicator light for each amplifier

channel.

With PowerCon NAC 3 FCA

connector. Only when the connector is inserted and

rotated (clicked) into place will the AC turn on. The

connector can be used as a switch, rotating the

connector to or from the locked position will turn the

unit on or off, respectively. Mute the signal feeding the

beforeturningtheunitonoroff.

With (white) PowerCon

NAC 3 DFCB connector. This is used as an AC loop

thru so that up to boxes can be power from

asingleACline.

Balanced signal XLR. Pin

assignmentsasfollows:

Used for paralleling several

units, which will share the same input. The output can

also be used to provide signal for an outboard power

amplifier.

INPUT

Rear panel of the AERO-38A amplifier.

F2-PowerCon NAC 3DFCB

HF

G-Input XLR

E-Fuse

H-Output XLR

F1-PowerCon NAC 3FCA

SIGNAL

MF

LF

ON

PROTECTION

DAAAB

ZOOM

HG

F1 E

F2

C

Low frequency mono-amplified system.

Nominal amplifier power (RMS) 1000W.

Amplifierpaneldescription:

mplifier limiter indicator lights.

When lit, the level of the signal source should be

reduced.

Signal presence indicator at the

amplifiers'inputs.

Indicator light for each amplifier

channel.

With PowerCon NAC 3 FCA

connector. Only when the connector is inserted and

rotated (clicked) into place will the AC turn on. The

connector can be used as a switch, rotating the

connector to or from the locked position will turn the

unit on or off, respectively. Mute the signal feeding the

beforeturningtheunitonoroff.

Balanced signal XLR. Pin

assignmentsasfollows:

Used for paralleling several

units, which will share the same input. Could also be

usedtoprovidesignalforanoutboardpoweramplifier.

H) : Used to control the

subwoofer level. To prevent accidental mis-setting, a

flat-blade screwdriver is needed to rotate the control,

which is recessed and detented. Depending on the

sensitivity, placement and configuration of your mid-

high system, you may need to adjust this control for

balancedfrequencyresponse.

INPUT

SUB LEVEL

NOTE: The amplifiers on the AERO-218A

and AERO-182A systems do not inlclude a filtered

satelliteoutputforAERO-38A systems.

A) : A

B) :

C) :

D) .

):

F) :

1=GND(ground)

2=(+)Noninvertedinput

3=(-)Invertedinput

G) :

LIMIT

SIGNAL

ON

FUSE

E AC INPUT

INPUT

LOOP THRU

3.2 AERO-182A

The required voltage for all models is:

115V, 50Hz/60Hz - 230V, 50Hz/60Hz

Maximum voltage (divide by 2 for115V):

264V

Shutdown voltage (divide by 2 for 115V):

Aero-38A: 156V

Aero-182A / Aero-218A: 160V

3.5 CURRENT CONSUMPTION

F

D

H

G

A

C

B

E

Amplifier panel on AERO-218A and AERO-182A

systems.

3.3 AERO-218A

The Aero-218A is a low frequency mono-

amplified system.

Nominal amplifier power (RMS) 2 x 1000W.

3.4 AC POWER REQUIREMENTS

AERO-182A / AERO-218A *

Maximum Power

AERO-38A

Maximum Power 8A

Sine 85Hz

2.5A

Pink noise

1/3 Power

3.2A

1/8 Power

1.6A

Idle

0.25A 0.25A

Data obtained at 230V, multiply per 2 for 115V.

*For 2000W versions multiply per 2.

Maximum power: Measured in conditions of severe

clipping.

1/3 Power

1/8 Power

Idle

Aero-38 Manual del usuario/ User´s manual 49

7A 2.5A

Sine 50Hz Pink noise

3.0A

----

----

1.1A

0.1A 0.1A

----

----

A sound system should be switched on

sequentially. Switch on the self-powered unit last in

your sound system. Switch on the sound sources

such as CD players or turntables, then the mixer, then

the processors, and finally the self-powered unit. If

you have several units, it is recommended that you

switchthemonsequentiallyoneatatime.

Follow the inverse order when switching off,

turning self-powered units off before any other

elementinthesoundsystem.

Mute all signal sources before switching the

unitonoroff.

It is recommended that the red LED

indicators are not lit continuously; at most it should

blinkonlyoccasionally.

If you wish to have a visual indication at the

mix position of whether the LIMIT LEDs are lighting,

during equipment set-up, closely observe what mixer

VUmeter level corresponds to the level that lights the

enclosure's LIMIT LEDs. That level that should not be

exceededduringtheevent.

LIMIT

Due to their high efficiency, the Aero Series

amplifiers generate very little residual heat and

therefore do not need a fan for cooling. In normal use,

theamplifierpanelwillbewarmtothetouch.

If the unit stops playing (or just the mid-high

or the bass sections), the amplifier's overheating

protection may be activated to protect the

componentsfromthermaldamage.

Overheating may be due to insufficient

cooling, or to very aggressive use in extremely hot

conditions. Do not use the unit in proximity to high

powerlights.

Once the amplifier cools down, it switches

back on automatically. If the unit should shut down

again, try reducing the volume a notch to avoid

overheating.

3.7 INDICATORSOVERLOAD (LIMIT)

3.6 SWITCH ON-OFF

3.8 OVERHEATING

3.10 LOW MAINS VOLTAGE

If mains voltage falls below the shutdown

voltage for the unit, it will stop playing. When

acceptable levels are regained, the unit will switch

backonautomatically.

3.9 ECUALIZATION

The AERO-38A can be used full-range. Full-

range use is only recommended for applications

where low SPL level and no bass reinforcement is

adequate. To use it in this mode simply plug the mixer

intotheenclosure'sinput.

The most common use will be combined

with the AERO-218A (AERO-182A). In this case

different outputs of the mixing console will be used

with the AERO-38A and the SUBS. Both sub systems,

AERO-182A and AERO-218A include signal treatment

in the amplifiers extending their frequency range up to

85Hz. As well, the amplifier of the AERO-38A

incorporates signal treatment which provides

frequency range extension down to 60Hz. Due to this

overlap between 60-85Hz the use of an

to control and adjust the phase of the subs

external

delay is

recommended.

3.11 CONNECTIONS

AERO-38A

Mezclador/Mixer

Retardo/

Delay

AERO-182A

Procesador/

processor

The connector is an output XLR

in parallel with the input connector and is useful for

daisy chaining the input signal to a number of boxes,

connectingtheminparallel.

The number of units that can be linked this

way depends on the output impedance of the

equipment driving the enclosure, such as the mixer or

processor. Typically, to avoid signal degradation, the

maximum number that can be daisy chained is given

by the formula Zc>10Zs, where Zc is the load

impedance and Zs is the output impedance of the

equipment driving the enclosure (mixer, console, etc).

For instance, a mixing console with 100 ohm output

impedance allows daisy chaining 20 boxes, when the

inputimpedanceofthecabinetsis20Kohm.

LOOP THRU

Aero-38 Manual del usuario/ User´s manual 50

The units do not need extreme EQ. Avoid

high levels of gain on the equalizers. Gain values

above +6 dB on a console's EQ are not

recommended.

Aero-38 Manual del usuario/ User´s manual 51

As can be seen in the diagram, independent signal lines exist for the subwoofer units, AERO-182A. The signal that

goestothesubsisprocessedbymeansoftheDSP-1Sub to adjust the delay between both systems.

3.12 RAIN PROTECTOR

Electronic devices can be damaged when

exposed to water or moisture. AERO-38A and AERO-

182A/218A amplifiers must be protected when

installed outdoors. A rain protector is supplied with

eachAERO-38A and AERO-182A/218Aunit.

The rain protector is specially designed to

withstand soft rain and other meteorological

conditions for short periods of time. In the case of

heavy rains, storms or permanent outdoors

installations the sound system must be protected

withadditionalelements.

The rain protectors supplied with each unit

havebeenmanufacturedwithfireproofmaterials.

The AERO-38A's rain protector features

severalsmall holes on the top side to allow convection

coolingoftheamplifier.

AERO-38 rain protector.

NOTE: The rain protector of the AERO-38A is different

fromtheonethatincludestheAERO-38.

AERO-38A rain protector.

3.13 HOW TO MAKE A PASSIVE

SYSTEM INTO A SELF POWERED ONE.

This way the amplifier of the AERO-38A

systemhasbeencorrectlyinstalledinthebox.

convert

loosen

r.

remove 14 x

AERO-38 -->AERO-38A:

AERO-38 passive systems come with a

metallic back plate, protected by a rain protector, that

features two Speakon NL8 connectors. To a

passive system into an active one, firstly the

screws 11x (3.9x19Pv00) and the rain protecto Once

this has been done, the M4x20 screws

thatfixthebackplatetothebox.

On the rear side of the back plate the cables

coming from the Speakon connectors lead to a white

male connector, which is inserted in a white female

connector attached to the box. Unplug the male

connector coming from the Speakon connectors and

insertthe male connector of the amplifier in the female

connectoronthebox.

The four M4x30 DIN 7985 must be screwed

in the four holes that can be seen on the radiator area.

The white arrows in the picture above point to the

mentionedholes.

Different rain protectors are needed for the

passiveandtheactiveversions!!!

The rain protector for the self powered

version is supplied with the amplifier. In order to

attach it to the box just rest the protector on the

receptacleandretightentheeleven3.9x19PV00on.

The white connector mentioned above can

be plugged only in one way, so a mistake in the

connections is mechanically impossible. Make sure

that the connection is tight enough, then put the

amplifier in its receptacle paying attention that wires

donotgetcaught.

The next step will be to fix the amplifier to

theboxwiththescrewssupplied:

10x(M4x20 DIN 965)

4x(M4x30 DIN 7985)

Aero-38 Manual del usuario/ User´s manual 52

Aero-38 Manual del usuario/ User´s manual 53

AERO-218Sub -->AERO-218A

To make a passive system into an active

one, firstly the back plate must be removed by

unscrewingthe12M4x20DIN965.

After cutting the speakers' wires on the

circuit board, terminals must be attached to the

speakers' wires as follows: to assure current polarity

attach large 6.3mm female terminal to the

black wire, and a smaller 4.8mm female

terminal to the red wire. Connecting the terminals to

the correct male terminals on the amplifier circuit

boardamplifie,thepolaritywillbecorrect.

faston

faston ,

faston

It is highly advisable to shield the terminals

withtapeorthermoretractablematerial:

Then the speaker wires must be cut from the

circuitboard.

NOTE: As AERO-218A and AERO 182A

amplifiers' polarity is inverted referenced to that of

conventional external amplifiers, the polarity of the

speakers' wires must be changed when switching

fromapassivetoanactiveAeroSeriessub.

-

Aero-38 Manual del usuario/ User´s manual 54Aero-38 Manual del usuario/ User´s manual

The large terminal

should be attached to the black wire, and the small

terminal should be attached to the

redwire:

faston

faston

6.3mm wide

4.8mm wide

In the case of the AERO-218A the same

processappliestothesecondamplifierinthebox.

Should you have any problem during this

process do not hesitate to contact D A S factory or

ourregionaldealer.

...

Aero-38 Manual del usuario/ User´s manual 55

PROBLEM CAUSE SOLUTION

1- Turn down the mixer's output.

3.14 TROUBLESHOOTING

No sound from the unit.

The presence LED

indicator(s) do(es) not light up.

SIGNAL

1- The signal source is sending

no signal.

2- Defective cable.

1- Check that the mixer or sound

source is sending signal to the UNIT.

2- Check that the cable from the

sound source to the UNIT is

connected correctly. Replace the

cable if defective.

Full power cannot be obtained.

The LED indicator(s) never

light(s) up.

LIMIT

1- The signal source does not have

a hot enough output.

1- If using a mixer, use the balanced

output if available. Use a professional

mixer with a hotter output.

Sound is distorted.

The LED indicator(s) is/are not

on, or only light up occasionally.

LIMIT

1- The mixer or signal source

is distorting.

1- Turn mixer channel gains down.

Check that none of your signal

sources are distorting.

Sound is distorted and very loud.

One or more LED indicators

light up.

LIMIT

1- The system is overloaded and

has reached maximum power.

Hum or buzz when a mixer

is connected to the unit.

1- The console probably has

un-balanced outputs. You may

be using an incorrect un-balanced

to balanced cable.

2- The mixer and the powered

speaker are not plugged into

the same mains outlet.

3- The audio signal cable is too

long or too close to an AC cable.

1- Read the appendix of this manual

to make a correct un-balanced to

balanced cable.

2- Connect the mixer and the unit

to the same mains outlet.

3- Use a cable that is as short as

possible and/or move the audio

signal cable away from mains cables.

Hum or buzz when using lighting

controls in the same building.

1- The audio signal cable is too

long or too close to the lighting cable.

2- On a sound system with three-

phase AC, the lighting equipment

and the UNIT are connected to

the same phase.

1- Move the audio signal cable away

from lighting cables. Try to find out

at what point the noise is leaking

into the system.

2- Connect the sound system to

a different phase than the lights.

You may need the help of an electrician

The power on LED indicator(s) do(es)

not light up when the power connector

is rotated and locked at the

ON position.(LOCK)

1 Bad or loose AC connection to

the UNIT or the mains outlet.

2 Faulty AC cable.

3 Blown Fuse.

1- Check you connections.

2- Check the cables, connectors

and AC power with a suitable

mains tester.

3- Replace fuse on fuse holder with

one of the same type. If it blows again,

take the unit to a service centre.

4. ASSEMBLING AN ARRAY

4.1TRANSPORTING THE CABINETS

AERO-38 units can be transported by using

the front panel dolly PL-38 or by using the PL-48S steel

dolly which can transport a maximum of 4 AERO-38

stacked.

The AERO-218Sub can be transported on

the rear located casters. Their rectangular shape

facilitates ground stacking without the use of the

rigging hardware. The AERO-182 cabinets can be

transportedbyusingthefrontpaneldollyPL-48.

4.2 PLANNING/INSPECTION

4.3 ASSEMBLING AN ARRAY “ONE

BY ONE”

When few units are to be used (minimum

systems recommended is 6 units) or when the dolly

platforms cannot be used due to a lack of space, the

enclosures will have to be hung “one by one”. The first

step will be to attach the AX-AERO48 or the AX-

AERO38 grid structure to the hoists. The chain slings

need to be attached to the structure using the

shackles provided with the grid. Once this has been

accomplished, the grid structure can be placed in a

vertical position by lifting the rear hoist and lowering

the front hoist so that the rear of the grid is on top and

the front of the grid at the bottom, ready to receive the

first box rolled into place by means of the PL-38 dolly

platform.

The next step is to attach the first unit to the

grid by introducing the G1A48 and G2A48 guides in

the receiving points of the grid structure and assuring

them with the six safety pins. The safety pins should

be inserted in the slot of the G2A48. It is very

important to make sure that the pins have been

insertedandlockedcorrectly.

Once the first unit of the array has been

attached to the AX-AERO48 or AX-AERO38, the

assembly should be lifted by way of the rear hoist until

the wheels of the PL-38 dolly platform lift off the

ground. From this point on, the front hoist can be used

tolifttheboxintoahorizontalposition.

Before installing the AERO systems it is a

good idea to run a simulation using the AEROWARE

program utilizing the venue dimensions. This way we

can determine the needs that should be met by the

rigging structures such as hoists, cranes, beams,

rigging points, etc. Besides providing weight

information, the program also provides users with

splay angle information, safety pin positions and

coveragepredictions.

Inspection is the next step after planning

and acquiring all the necessary parts needed to

elevate the systems. All parts, including the hardware

attached to the enclosure, the safety pins, etc. should

be thoroughly inspected before each use. Units

exhibiting deformations, cracks or any other defect

shouldbereplacedwithnewunits.

It is extremely important to assure that each

and every one of the aforementioned structures is

capable of supporting a superior load than that of the

completesystem.

It is important to establish an inspection

routine for the complete rigging system before each

event or installation as well as establishing the

maximumloadspecificationsofthehoiststobeused.

Rigging should be carried out by experts

familiar with the way the systems function and their

characteristics.

On occasions, it may be convenient to have

additional tie down points to impede the array from

twistingorswinging.

Aero-38 Manual del usuario/ User´s manual 56

AX-AERO48 (AX-AERO38)

1

2

3

4

5

6

Quick release pin must be

inserted thru the slot of G2A48.

3y4

Same process for AERO-182

AERO-38

Once the first box has been placed at 0º and

raised approximately 75cm (30 in) the second box of

the array can be rolled into place. Once located in

position, the G2A48 guides of the second box should

be freed and inserted in the rear located receiving

points of the suspended box and secured with the

safetypins.

Swing the G2A48 guide

into place and secure it

with the safety pin.

Once the splay angle between the first two

boxes has been determined, the front of the box can

be lifted into place. Three people will be needed to

undertake this operation, two to lift the box and one to

fittheG1A48guideandsafetypinsintotheupperbox.

57Aero-38 Manual del usuario/ User´s manual

Lifted by way of the rear hoist

until the wheels of the PL-38

dolly platform are off the ground.

Lift with the front hoist

until the box is in a

horizontal position.

0º

Lift the box and free

the G1A48 guides.

AX-AERO48 (AX-AERO38)

1

2

3

4

5

6

Quick release pin must be

inserted thru the slot of G2A48.

3y4

AERO-38

Once the boxes have been joined, the front

dolly panels can be removed. The next boxes should

be attached “one by one” using the methods

described. Finally, the array should be hoisted to the

correct height and secured with slings to avoid

swinging. This method is more time consuming than

assembling an array by the “all at once” procedure,

but is appropriate for situations due to a lack of space

in which to array the system. During the process, the

safety pins should be checked making sure they are

secured correctly. Once the complete array has been

lifted into place, additional slings should be attached

tosecurethearrayandavoidswinging.

AERO-182 systems can be flown one by one

asdescribedpreviously!!.

4.4 ASSEMBLING AN ARRAY USING

THE PL-38 PLATFORM

The PL-38 platform can be used to easily

transport AERO-38 units to the assembling area. To

use this method of assembling and hoisting the array,

there must be enough space to permit linking all the

boxesfromthefrontofthetherigginghardware.

The first step will be to attach the AX-

AERO48 or AX-AERO38 grid and the 2 hoists. Once

this has been accomplished, the grid structure can be

placed in a vertical position by lifting the rear hoist and

lowering the front hoist so that the rear of the grid is on

top and the front of the grid at the bottom, ready to

receivethefirstbox.

Rigging points

The next step is to attach the first unit to the

grid by introducing the G1A48 and G2A48 guides in

the receiving points of the grid structure and assuring

them with the (6) safety pins. The safety pins should

be inserted in the slot of the G2A48. It is very

important to make sure that the pins have been

insertedandlockedcorrectly.

58Aero-38 Manual del usuario/ User´s manual

Lift the box and introduce the

G1A48 guides securing them

with the safety pins.

Once the first box is attached to the

structure, the remaining boxes should be brought to

the array and attached repeating the previous steps (1

and 2) using G1A48 guides and safety pins per side

making sure that the pins have been inserted and

lockedcorrectly.

Proceed to attach the remaining units in the

same manner until all the array units are attached to

one another. For example, if we are assembling a six

unit array, the process will be repeated six times.

When all the units are attached, the complete array is

readytobehoisted.

When the rear of the enclosures come

together, the G2A48 rear guides should be positioned

(4) into the hardware of the box above, inserting (5)

the safety pins in the correct angle position. Since the

boxesareflown,thesafety pins should be in the slot of

theG2A48guide.

As the array assembly is lifted (6 & 7), the

PL-38platformsshouldberemoved.

Once the complete array has been lifted into

place, additional slings should be attached to secure

thearrayandavoidswinging.

The front motor will be used only to take up

slack in the chain, all the weight should be on the rear

hoist. When the wheels of the last enclosure are off

thegroundthearraycanbeliftedwithbothmotors.

59Aero-38 Manual del usuario/ User´s manual

The complete assembly should begin being

lifted from the rear hoist (3) so that the rear of the

enclosures come together due to their trapezoidal

shape. The front motor will be used only to take up

slack in the chain, all the weight should be on the rear

hoist. Proceed in this manner until the wheels of the

last enclosure are off the ground. From here on, the

arraycannowbeliftedwithbothmotors.

G1A48 2

1

G2A48

3

4

5

Rear hoist!!

7

6

Rear hoist FIRST!!

Manual del usuario/ User´s manual 60Aero-38

This manual suits for next models

5

Table of contents

Other D.A.S. Speakers System manuals

D.A.S.

D.A.S. Aero 2 Series Quick start guide

D.A.S.

D.A.S. AERO-12A User manual

D.A.S.

D.A.S. ST Series User manual

D.A.S.

D.A.S. Sound Force SF-112 User manual

D.A.S.

D.A.S. arco 4 User manual

D.A.S.

D.A.S. Sound Froce SF-158 User manual

D.A.S.

D.A.S. ARA Series User manual

D.A.S.

D.A.S. EVENT-208A Quick start guide

D.A.S.

D.A.S. EVENT SERIES User manual

D.A.S.

D.A.S. AXS-40UX User manual