D-Industrial Technology Q200 User manual

Uson

Q200 User Manual

Revison 10

Updated September 2018

Q200 User Manual Preliminary

196045/Issue 10 i

Disclaimer

D-Industrial Technology Ltd. makes no representations or warranties with respect to the

contents or use of this manual and specifically disclaims any express or implied warranties of

merchantability or fitness for any particular purpose. Further D-Industrial Technology Ltd

reserves the right to revise this manual and to make changes to its content, at any time, without

obligation to notify any person or entity of such revisions or changes.

Copyright

No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose other than the

purchaser's personal use without the written consent of the copyright holder.

©D-Industrial Technology Ltd, October 2003-2016. All rights reserved.

Trademarks

Q200 ®is a registered trademark of D-Industrial Technology Ltd

SPC-PC IVTM is a registered trademark of Quality America, Inc.

WindowsTM is a trademark of Microsoft Corporation.

Sales and Support

US and North America

Creative Solutions

PO Box 14511

Scottsdale, AZ 85267

+1 512 588-2002

Q200 User Manual Preliminary

200120/Revision 10 i

Document History

Part Number: 200120

Revision History:

Issue Change

Note Date Description

1 N/A 04/02/1994 First Edition

2 N/A 12/03/1994 First Revision

3 N/A 14/12/1994 Second Revision

4 1348 06/01/1995 Spares Updated

5 1415 25/01/1996 EC Revision

6 0051 02/07/1997 Sinter References

7 0263 08/11/1999 H, M & L Sinters. Fixed exponent display

8 0536 05/02/2002 Sales support information and document format

updated.

9 0627 1/10/2003 Sales support information updated

10 0760 2/26/2007Added ROHS declaration

Preliminary Q200 User Manual

ii 200120/Revision 10

About This Manual

This manual is designed to provide full information about the setting up and use of the

Q200.

•Section 1 WARNING AND CAUTIONS gives general information to be aware

of when installing or using the Q200.

•Section 2 INTRODUCTION gives a general introduction to the Q200 and its

operation.

•Section 3 UNPACKING provides a checklist for the components supplied with

the Q200.

•Section 4 INSTALLATION REQUIREMENTS explains the installation

requirements for the Q200 before use.

•Section 5 CONSOLE FAMILIARISATION familiarises the user with the Q200's

console and front panel interface.

•Section 6 HAND UNIT FAMILIARISATION familiarises the user with the hand

unit, key panel and controls.

•Section 7 POWER UP AND INSTALLATION this section describes how to

switch the Q200 on and the initialisation routine that follows.

•Section 8 PROGRAMMING THE Q200 gives a detailed description of each

program function and instructions for viewing and altering them.

•Section 9 CALIBRATING THE Q200 describes the procedure for calibrating

the Q200 to a standard leak.

•Section 10 THE Q200 IN USE gives guidance on the precautions that may

need to be taken when calibrating and using the Q200 in a typical industrial

environment.

•Section 11 INTERFACING THE Q200 describes how the Q200 can be

connected to peripheral devices such as printers or chart recorders.

•Appendix A Q200 Specification gives a full specification for the Q200.

•Appendix B Preventative Maintenance gives information on general

preventative maintenance for the Q200.

•Appendix C Fault/Error/Warning Messages explains possible fault, error and

warning conditions and suggests corrective actions.

•Appendix D Spares/Options List gives a list of the spares and options available

for the Q200.

•Appendix E RS232 Connector Details lists the pin-outs and connectors for the

Q200.

•Appendix F Applications describes some of the typical application areas in

which the Q200 is used.

Q200 User Manual Preliminary

200120/Revision 10 iii

•Appendix G Changing the Internal Gas Cylinder details the procedure for

changing the internal gas cylinder on the Q200.

•Appendix H Installing/Changing the Battery details the procedure for installing

and changing the battery on the Q200.

•Appendix I Changing The Probe/Sinter details the procedure for changing the

Q200's hand unit probe and sinter.

•Appendix J Leak Rate and Concentration Formulae lists the formulae for

converting between leak rates in different units and between leak rate and

concentration.

•Appendix K Program Structure details the program structure for reference

when programming the Q200 for use.

•Glossary of terms used within this manual.

•Index.

Q200 User Manual Contents

200120/Revision 10 1

Table of Contents

Disclaimer.........................................................................................................................i

Copyright..........................................................................................................................i

Trademarks......................................................................................................................i

Sales and Support............................................................................................................i

Document History.............................................................................................................i

About This Manual ..........................................................................................................ii

Table of Contents........................................................................................................... 1

1.0 WARNING AND CAUTIONS............................................................................1-1

1.1 HAND UNIT DETECTOR..............................................................................1-1

1.2 Sinter.............................................................................................................1-1

1.3 Configuring the Q200....................................................................................1-1

1.3.1 Changing from capillary mode to sinter mode.........................................1-2

1.3.2 Changing from sinter mode to capillary mode.........................................1-2

1.3.3 Changing between sinters.......................................................................1-3

1.3.4 Re-configuring the instrument..................................................................1-3

1.3.5 Measuring ranges and configuration codes.............................................1-4

1.4 ARGON GAS SUPPLY.................................................................................1-5

1.5 POWER SUPPLY .........................................................................................1-5

1.6 TRANSPORTING THE Q200........................................................................1-6

1.7 DISPOSAL....................................................................................................1-6

1.8 ENVIRONMENTAL.......................................................................................1-6

1.9 EC DECLARATION OF CONFORMITY .......................................................1-7

2.0 INTRODUCTION..............................................................................................2-1

3.0 UNPACKING....................................................................................................3-1

4.0 INSTALLATION REQUIREMENTS..................................................................4-1

4.1 REMOVING THE CASE LID.........................................................................4-1

4.2 GAS SUPPLY ...............................................................................................4-1

4.3 POWER SUPPLY .........................................................................................4-2

4.4 STORAGE AND OPERATING ENVIRONMENT ..........................................4-2

4.5 OPERATING MODES...................................................................................4-2

4.5.1 PORTABLE INSTALLATION...................................................................4-2

4.5.1.1 CHECKING THE INTERNAL ARGON SUPPLY..............................4-3

4.5.1.2 CHECKING THE BATTERY............................................................4-3

4.5.2 FIXED INSTALLATION............................................................................4-3

4.5.2.1 RUNNING FROM AN EXTERNAL GAS SUPPLY...........................4-3

4.5.2.2 RUNNING FROM THE EXTERNAL POWER SUPPLY...................4-4

5.0 CONSOLE FAMILIARISATION........................................................................5-1

5.1 FRONT PANEL LAYOUT .............................................................................5-1

5.1.1 KEY-SWITCH ORIENTATION.................................................................5-1

5.1.2 FRONT PANEL KEYS.............................................................................5-2

5.1.3 BATTERY CHARGER INDICATOR.........................................................5-2

6.0 HAND UNIT FAMILIARISATION......................................................................6-1

6.1 HAND UNIT KEYS........................................................................................6-2

6.2 HAND UNIT INDICATORS ...........................................................................6-2

6.2.1 WARNING LED .......................................................................................6-2

6.2.2 PEAK HOLD LED....................................................................................6-2

6.3 HAND UNIT BAR GRAPH DISPLAY............................................................6-2

7.0 POWER UP AND INSTALLATION...................................................................7-1

7.1 SWITCH ON .................................................................................................7-1

7.2 INSTALLATION ............................................................................................7-1

8.0 PROGRAMMING THE Q200............................................................................8-1

8.1 CALIBRATE MENU ......................................................................................8-1

8.1.1 CALIBRATION LEVEL.............................................................................8-1

8.1.2 RE-CALIBRATION INTERVAL................................................................8-2

Q200 User Manual Contents

2200120/Revision 10

8.1.3 CALIBRATION FACTOR..........................................................................8-3

8.2 CONFIGURE MENU .....................................................................................8-3

8.2.1 CLEAN TIME............................................................................................8-3

8.2.2 ALARM LEVEL.........................................................................................8-3

8.2.3 TRACE GAS CONCENTRATION ............................................................8-4

8.2.4 AUTO ZERO ............................................................................................8-5

8.2.5 DISPLAY TYPE........................................................................................8-5

8.2.6 RESET PARAMETERS............................................................................8-6

8.2.7 GAS SUPPLY...........................................................................................8-6

8.3 DIAGNOSTICS MENU ..................................................................................8-7

8.3.1 BATTERY VOLTAGE...............................................................................8-7

8.3.2 TEMPERATURE......................................................................................8-7

8.3.3 DETECTOR FREQUENCY......................................................................8-7

8.3.4 RE-CALIBRATION...................................................................................8-8

8.3.5 SOFTWARE VERSION NUMBER ...........................................................8-8

8.4 SET DATE/TIME MENU................................................................................8-8

8.4.1 DATE........................................................................................................8-8

8.4.1.1 DAY..................................................................................................8-9

8.4.1.2 MONTH ............................................................................................8-9

8.4.1.3 YEAR................................................................................................8-9

8.4.2 TIME.......................................................................................................8-10

8.4.2.1 HOURS...........................................................................................8-10

8.4.2.2 MINUTES .......................................................................................8-10

8.5 EXITING THE MENU STRUCTURE ...........................................................8-11

9.0 CALIBRATING THE Q200................................................................................9-1

10.0 THE Q200 IN USE.......................................................................................10-1

10.1 STANDBY MODE........................................................................................10-1

10.2 SAMPLE MODE ..........................................................................................10-1

10.3 INSTRUMENT CALIBRATION....................................................................10-2

10.4 GENERAL TIPS ON LEAK DETECTION....................................................10-3

10.5 ADJUSTING THE VOLUME........................................................................10-6

10.6 BACKGROUND CONTAMINATION............................................................10-6

10.7 RESULTS STORAGE AND PRINTOUT......................................................10-7

11.0 INTERFACING THE Q200 ..........................................................................11-1

11.1 INTERFACING TO A PRINTER..................................................................11-1

11.2 INTERFACING TO A CHART RECORDER................................................11-1

Appendix A Q200 Specification.................................................................A-1

Appendix B Preventative Maintenance .....................................................B-1

Appendix C Fault/Error/Warning Messages..............................................C-1

Appendix D Spares/Options List ...............................................................D-1

Appendix E RS232 Connector Details ......................................................E-1

Appendix F Applications............................................................................ F-1

Appendix G Changing the Internal Gas Cylinder ......................................G-1

Appendix H Installing/Changing the Battery..............................................H-1

Appendix I Changing The Probe/Sinter.......................................................I-1

Appendix J Leak Rate and Concentration Formulae..................................J-1

Appendix K Program Structure..................................................................K-1

Glossary.......................................................................................................................L-1

Index................................................................................................................................i

Q200 User Manual Contents

200120/Revision 10 3

List Of Figures

Figure 1: Q200 Case Lid Containing Accessories.......................................................3-1

Figure 2 Removing the Case Lid.................................................................................4-1

Figure 3: Front Panel Layout.......................................................................................5-1

Figure 4: Hand Unit Display and Keyboard.................................................................6-1

Figure 5: Changing the Internal Gas Cylinder............................................................ G-1

Figure 6: Changing the Battery ...................................................................................H-1

Figure 7: Fitting the Probe............................................................................................I-1

Figure 9: Location of Sinter..........................................................................................I-2

Figure 10: Q200 Menu Structure.................................................................................K-1

Q200 User Manual WARNING AND CAUTIONS

200120/Revision 10 1-1

1.0WARNINGAND CAUTIONS

This section explains the warnings and cautions that should be observed when

installing or using the Q200.

1.1 HAND UNIT DETECTOR

The detector operates at elevated temperatures; the user should proceed with caution

whenever the hand unit nozzle is removed.

The detector contains a radioactive source that should never be tampered with. The

detector contained within the hand unit has the following characteristics:

Nuclide Nickel 63

Radiation Beta rays

Content 370 MBq

Beta energy 60 keV Max

Range in air 50 mm approximately

Half-life 100 years

The primary Beta rays are completely contained within the detector cell and provide no

hazard to the user during normal operation. National Regulations relating to the control

of radioactive sources vary from country to country. It is a requirement in some

countries, and a practice that we would recommend that a competent person be

appointed to be responsible for the instrument. Their duties would be to ensure proper

care is taken of the instrument and all users are instructed in the use of the instrument

and not to attempt access to the radioactive sources. In the event of damage or loss

occurring, there may be a requirement to notify the competent authority.

Specific instructions may accompany this manual describing any further national

regulations governing the use, storage and transportation of equipment containing

radioactive sources. In the UK the radioactive source must be checked at least every

24 months for leakage. The supplier of the equipment can provide this service.

1.2 SINTER

Periodically the user should remove the nozzle and inspect the sinter, see Appendix I

for more information. A new sinter should be fitted if the current sinter is discoloured

indicating deposits of contaminants exist on its surface. Progressive blockage of the

sinter can also be observed by progressive reduction in detector response to standard

leaks or increasing calibration factors when performing calibration sequences.

1.3 CONFIGURING THE Q200

The Q200 has been factory configured to match your requirements with respect to

language option, the type of trace gas to be used, probe type and the displayed units.

If a configuration change is required, it can be performed as detailed below.

Q200 User Manual WARNING AND CAUTIONS

1-2 200120/Revision 10

1.3.1 CHANGING FROM CAPILLARY MODE TO SINTER MODE.

CAUTION: Before changing the hand unit probe ensure that the hand unit

detector block is cool.

1. Remove the capillary probe nozzle from the nozzle cone by pulling the probe

nozzle out of the nozzle cone. Ensure that the capillary probe nozzle is pulled

out of the nozzle cone in the line of the hand unit to avoid bending the capillary

probe needle.

2. Unscrew the nozzle cone from the hand unit.

3. Unscrew the capillary needle probe and its housing from the front face of the

detector assembly and store in a clean dry place. Note that the small knurled

cap on the housing retains the capillary needle probe in the housing.

Unscrewing the housing using the larger knurled flange adjacent to the front

face of the detector assembly will allow the needle probe and its housing to be

removed from the detector assembly as a single entity.

4. Locate the required sinter and inspect the seal around the periphery of the

sinter to ensure that it is not damaged. Damage to the seal will compromise the

performance of the instrument by allowing an excessive amount of air to enter

the detector. Appendix D contains details of replacement seals that can be

fitted to the sinter. Fit the sinter into the front of the detector assembly. Use a

broad flat bladed screwdriver to tighten the sinter into the detector assembly.

5. Screw the nozzle cone back into place on the hand unit.

6. Push the sinter probe nozzle firmly into the nozzle cone.

7. Re-configure the instrument as outlined in 1.3.3.

8. Perform a cleaning cycle of at least one hour.

1.3.2 CHANGING FROM SINTER MODE TO CAPILLARY MODE.

CAUTION: Before changing the hand unit probe ensure that the hand unit

detector block is cool.

1. Unscrew the nozzle cone from the hand unit.

2. Using a broad bladed screwdriver, unscrew the sinter assembly from the front

face of the detector assembly and store in a clean dry place.

3. Remove the sinter probe nozzle from the nozzle cone.

4. Locate the capillary needle probe and it’s housing and inspect the seal around

the periphery of the housing to ensure that it is not damaged. Damage to the

seal will compromise the performance of the instrument by allowing an

excessive amount of air to enter the detector. Appendix D contains details of

replacement seals that can be fitted to the housing. Screw the capillary needle

probe and its housing into the front face of the detector assembly until finger

tight.

5. Screw the nozzle cone back into place on the hand unit.

WARNING AND CAUTIONS

Q200 User Manual

200120/Revision 10 1-3

6. Push the capillary probe nozzle over the capillary needle probe and into the

nozzle cone, taking care to ensure that no bending stresses are applied to the

capillary needle probe.

7. Re-configure the instrument as outlined in 1.3.3.

8. Perform a cleaning cycle of at least one hour.

1.3.3 CHANGING BETWEEN SINTERS

CAUTION: Before changing the hand unit probe ensure that the hand unit

detector block is cool.

1. Unscrew the nozzle cone from the hand unit.

2. Using a broad bladed screwdriver, unscrew the sinter assembly from the front

face of the detector assembly and store in a clean dry place.

3. Locate the required sinter and inspect the seal around the periphery of the

sinter to ensure that it is not damaged. Damage to the seal will compromise the

performance of the instrument by allowing an excessive amount of air to enter

the detector. Appendix D contains details of replacement seals that can be

fitted to the sinter. Fit the sinter into the front of the detector assembly. Use a

broad flat bladed screwdriver to tighten the sinter into the detector assembly.

4. Screw the nozzle cone back into place on the hand unit.

5. Re-configure the instrument as outlined below.

6. Perform a cleaning cycle of at least one hour.

1.3.4 RE-CONFIGURING THE INSTRUMENT

1. Switch the instrument on and ensure that the security key-switch is in the

program position.

2. With the console display reading 'Calibrate' press the Zero (hand unit) key

and the Standby\Run (console) key simultaneously. This will bring up a four-

digit numeric configuration code on the console display. The first digit of the

code will be flashing.

Digit 1234

Code 1234

Code

Digit 1: Agent: 0. English

WARNING AND CAUTIONS

Q200 User Manual

1-4 200120/Revision 10

1. American

2. German

Digit 2: Units: 0.ml/s

1. ppm

Digit 3: Gas Type: 0. SF6

1. Undefined

Digit 4: Probe Type: 0. H Sinter

1. Capillary

2. M Sinter

3. L Sinter

3. Using the Increment \ Decrement , Scroll Left \ Scroll Right keys the

desired configuration code can be entered. If the operator then presses the

Select key the instrument will verify that the code entered is a valid one. If an

invalid code is entered, then an 'Invalid Code' message will be displayed for a

two second interval, then the operator will be given two further chances to re-

enter a valid code. If a valid code is not entered within three attempts the

instrument will revert back to the 'Configure' prompt.

4. If the Select

key is pressed with a valid code being displayed, a 'Valid Code'

message will be displayed for a two-second interval. The instrument will then

perform to the new configuration parameters. Note that changing the

configuration code clears existing parameters and will set calibration and alarm

levels to the default values for the new configuration.

CAUTION: If the instrument is re configured then it should be re calibrated as

described in this manual.

1.3.5 MEASURING RANGES AND CONFIGURATION CODES

The following tables illustrate the measuring ranges available for the various inlet

probes based on 100% trace gas concentration:

Q200 User Manual WARNING AND CAUTIONS

200120/Revision 10 1-5

Leak-Rate Measuring Ranges For SF6 / ml/s

Probe Type Capillary H Sinter M Sinter L Sinter

Range 0.0 x 10-10

⇓

1.8 x 10-7

0.0 x 10-8

⇓

1.8 x 10-5

0.0 x 10-7

⇓

1.8 x 10-4

0.0 x 10-6

⇓

1.8 x 10-3

Alarm/Cal. 1.0 x 10-10

⇓

1.8 x 10-7

1.0 x 10-8

⇓

1.8 x 10-5

1.0 x 10-7

⇓

1.8 x 10-4

1.0 x 10-6

⇓

1.8 x 10-3

Config. Code 0001 0000 0002 0003

Concentration Measuring Ranges For SF6 / ppm

Probe Type Capillary H Sinter M Sinter L Sinter

Range N/A 0.0

⇓

18.09

0.0

⇓

180.0

0.0

⇓

1800

Alarm/Cal. N/A 0.01

⇓

18.00

0.1

⇓

180.0

1

⇓

1800

Config. Code N/A 0100 0102 0103

When the M or L Sinters or the Capillary probe are fitted, the ranges over which the

instrument may be calibrated are automatically changed to match the usable range of

the instrument. Appendix A contains a full list of the operating, calibration and alarm

ranges for all the inlet probes over a range of trace gas concentrations.

1.4 ARGON GAS SUPPLY

The instrument requires a supply of Argon that is at least 99.998% pure. This is

supplied with the instrument in a gas cylinder that conforms to BS 5045/3/B.

The gas cylinder should be filled to a pressure no greater than 200 bar (2900 PSIG)

maximum, and regularly checked for damage or fatigue and that the cylinder is still

within the validity of the test period indicated by the plastic collar on the stem of the

cylinder valve.

If an external gas supply is used the pressure supplied to the inlet port should not

exceed 4 bar (58 PSIG) maximum.

1.5 POWER SUPPLY

The instrument is supplied with an internal 12 Volt, gel electrolyte battery and a battery

charger. Both items are designed for use with the Q200 only. The manufacturer

accepts no responsibility if either item is operated with any equipment other than the

Q200. Information on spares may be found in Appendix D.

The battery charger must be run only from a mains supply that has a protective earth. It

is designed to be used on a flat surface next to the instrument and with adequate

clearance for ventilation. It should not be used whilst still located in the lid infill.

Q200 User Manual WARNING AND CAUTIONS

1-6 200120/Revision 10

The internal 12 Volt battery has inline protective fuse T2A/250V. A replacement fuse

must be of an appropriate type and rating.

1.6 TRANSPORTING THE Q200

Transport of the instrument is subject to regulation in most countries. It is also subject

to international rules when transportation is between two different countries. If the

instrument needs to be transported, seek expert advice prior to shipping.

1.7 DISPOSAL

If there is an accident that damages the hand unit beyond repair or when the

instrument has exceeded its useful life, the unit must be disposed of through an

approved contractor. In the United Kingdom, the manufacturer can accept units for

disposal. Note that a charge will be made for the disposal of radioactive sources. In

other countries, the National Radiological Protection Organisation should be contacted

for advice.

1.8 ENVIRONMENTAL

Do not use the instrument:

•In explosive atmospheres.

•Outside the specified operating temperature range.

•With hazardous or toxic gases.

•In an environment where water could be drawn into the probe.

•Where the variation in background level is greater than the calibration level.

WARNING AND CAUTIONS

Q200 User Manual

200120/Revision 10 1-7

1.9 EC DECLARATION OF CONFORMITY

As detailed under the following:

•The European Low Voltage Directive 73/23/EEC (amended by 93/68/EEC).

•The Electromagnetic Compatibility Directive 89/336/EEC (amended by 91/263/EEC

and 92/31/EEC), the declaration of conformity is provided for the following:

Equipment: Q200 Trace Gas Leak Detector

Manufacturer: Uson Ltd

WesternWay

Bury St. Edmunds

Suffolk

United Kingdom

IP333SP

Transposed Harmonised Standards: BS EN 61010-1:1993 Safety requirements

for electrical equipment for measurement,

control and laboratory use.

BS EN 50081-1:1992 Electromagnetic

Compatibility: Generic emission standard

for light industry.

BS EN 50082-1:1992 Electromagnetic

Compatibility: Generic immunity standard

for light industry.

Name Of Responsible Person: Mr A Hawes

Signature:

Date: 12 March 1996

Position: Senior Development Engineer.

Address Of Responsible Person: Uson Ltd

WesternWay

Bury St. Edmunds

Suffolk

United Kingdom

IP333SP

Q200 User Manual INTRODUCTION

200120/Revision 10 2-1

2.0INTRODUCTION

The Q200 is a high sensitivity leak detector used to locate and quantify leaks with

electron capturing trace gases. The instrument may be used in a variety of industrial

and scientific applications and environments. It is lightweight and robust and comprises

a hand unit, control console, rechargeable battery and Argon gas cylinder, contained

within a case for complete portability. Facilities are built in to allow the instrument to be

operated using external gas and power supplies.

The instrument is microprocessor based, using a Vacuum Fluorescent Display (VFD) to

provide a rapid and accurate readout of leak rates. The built-in memory is capable of

storing up to one hundred separate leak rate readings, which can be output to a printer

via the built in RS232 interface connector.

The detection principle uses a single Electron Capture Detector (ECD), utilising a low

power radioactive source contained within the hand unit. To measure for leaks, the

component under test is filled with a trace gas until there is a slightly higher pressure

than ambient within the component. This condition will cause the trace gas to leak

through any cracks, holes or porous areas within the component. Leaking trace gas will

then be detected and quantified by the Q200.

Each instrument is factory configured for a specific trace gas and measurement unit.

By default the instrument is configured for SF6although configuration for other gases is

available on special order.

This manual is written specifically for an instrument configured to SF6, H Sinter

and ml/sec. Instruments configured for other gases, sinters and units will

perform identically except that some display formats are different, and the range

and step sizes for calibration and alarm levels are different. The user may

convert between leak rates in different units by referring to Appendix J.

Table of contents

Popular Security Sensor manuals by other brands

GJD

GJD D-TECT Dual Tech GJD360/AM installation guide

Optex

Optex WX Infinity Series installation instructions

DSC

DSC PowerG PG9985 installation guide

Philio Technology Corporation

Philio Technology Corporation PSP05-A manual

GasTech

GasTech F-GUARD IR3-HD user manual

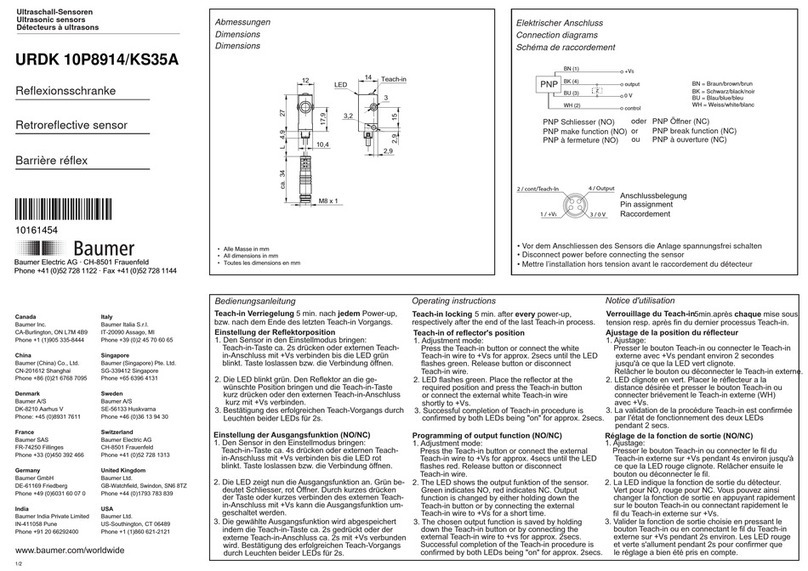

Baumer

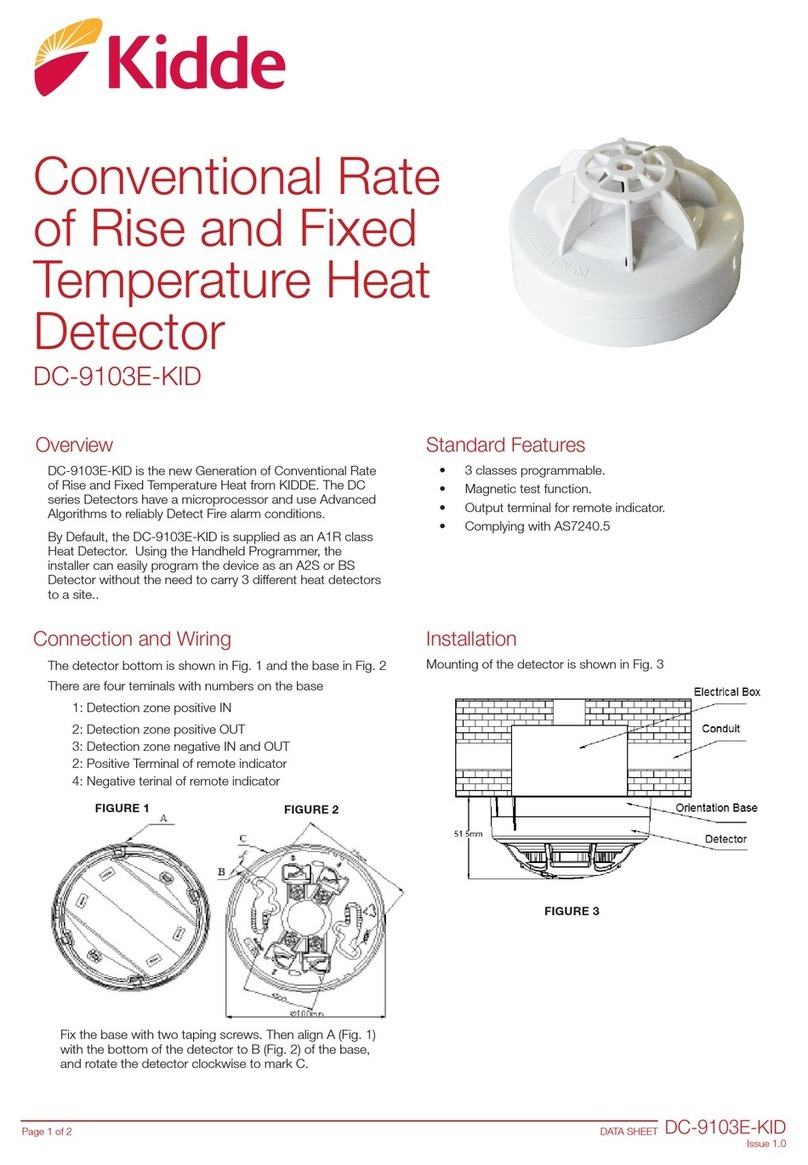

Baumer URDK 10P8914/KS35A quick start guide

Theben

Theben compact office quick start guide

B.E.G. LUXOMAT

B.E.G. LUXOMAT PD2-M-DALI/DSI-1C Installation and operating instruction

MKS

MKS Ophir FPD-IG-175 user manual

Baumer

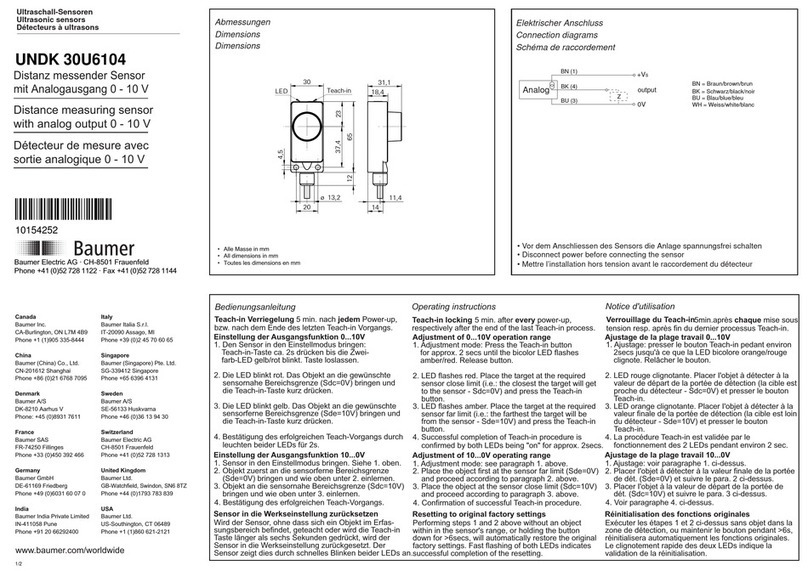

Baumer UNDK 30U6104 quick start guide

IMMOOS

IMMOOS SS1 mGB operating instructions

Eaton

Eaton MAB50R Installation and operation manual