6.4 Installation of damping devices

6.4.1 Damping devices

By means of t installation holes on the steel frame of the unit

base, the unit can be fastened on the foundation through the

spring damper. See Fig.6-7,6-8,6-9(Schematic diagram of

installation dimension of the unit) for details about center

distance of the installation holes. The damper does not go with

the unit, and the user can select the damper according to the

relevant requirements. When the unit is installed on the high

roof or the area sensitive to vibration, please consult the

relevant persons before selecting the damper.

6.4.2 Installation steps of the damper

Step 1. Make sure that the flatness of the concrete foundation

is within ±3mm, and then place the unit on the cushion block.

Step 2. Raise the unit to the height suitable for installation of

the damping device.

Step 3. Remove the clamp nuts of the damper. Place the unit

on the damper, and align the fixing bolt holes of the damper

with the fixing holes on the unit base.

Step 4. Return the clamp nuts of the damper to the fixing holes

on the unit base, and tighten them into the damper.

Step 5. Adjust the operational height of the damper base, and

screw down the leveling bolts. Tighten the bolts by one circle to

ensure equal height adjustment variance of the damper.

Step 6. The lock bolts can be tightened after the correct

operational height is reached.

Damping device

Anchor bolt

Nut

Ferrol

It is recommended that the damper should be fastened on the

foundation with the provided holes. After the unit is placed on the

foundation, the damper connected with the unit should not be

moved, and the central clamp nut is not allowed to be tightened

before the damper sustains load.

Fig. 6-10 Installation of the damper

NOTE

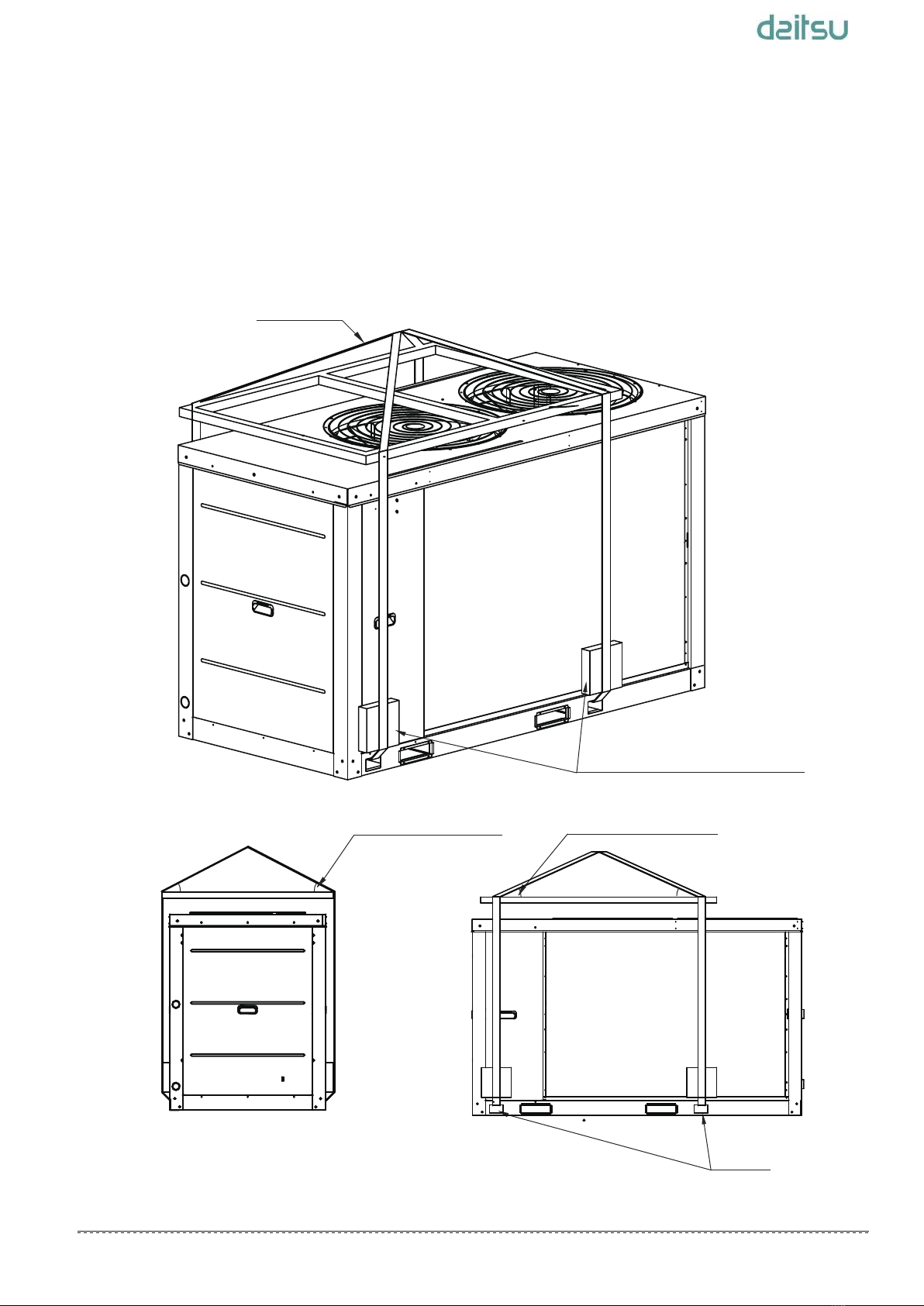

6.5 Installation of device to prevent snow

build-up and strong breeze

(e) Equipment covered with snow

(d) Air inlet blocked by snow

(b) Snow accumulated

on the top plate

(

c) Snow falling on the equipment

(a) Buried in the snow

6.5.1 Measures used to prevent problems caused by

snow

a. Measures to prevent build-up of snow

The base height should be as least the same as the predicted

snow depth in the local area.

b. Lightning protection and snow protection measures

6.5.2 Precautions for designing a snow cover

Monsoon

Outdoor

unit

Base height

Fig. 6-11 Types of problems caused by snow

Fig. 6-12 Snow prevention base height

When installing an air-cooled heat pump chiller in a place with

heavy snow, it is necessary to take snow protection measures to

ensure trouble-free operation of the equipment.

Otherwise, accumulated snow will block the air flow and may cause

equipment problems.

Check the installation site thoroughly; do not install the equipment

under awnings or trees or a place where snow is piled up.

a. To ensure a sufficient air flow required by the air-cooled heat

pump chiller, design a protective cover to make the dust

resistance 1 mm H2O or less lower than the allowable external

static pressure of air-cooled heat pump chiller.

b. The protective cover must be strong enough to withstand the

snow weight and the pressure caused by strong wind and

typhoon.

c. The protective cover must not cause short circuit of air

discharge and suction.

8

Installation Manual___________________________________________________________________________________