DAAB OUTPUT CARD DB406 INSTRUCTION MANUAL

5

Installing the Delta VFD-EL frequency converter

• Modification of the motor winder

e following criteria must be met in order to use the DAAB motor winder with the frequency converter:

• e limit switch cams must be wider than normal.

• FAAC Nordic AB recommends using a motor with a speed of 2,800 rpm.

• Programming the frequency converter

In start mode F XX (XX = frequency) is displayed. Press the ENTER button to enter programming mode (press the button

once for X-). Select the desired group and press ENTER again – (X-XX) is displayed. Select the desired channel and press

ENTER again – (dX) is displayed. Set the desired value, press ENTER again, when the channel is displayed again press

MODE until the display returns to F XX.

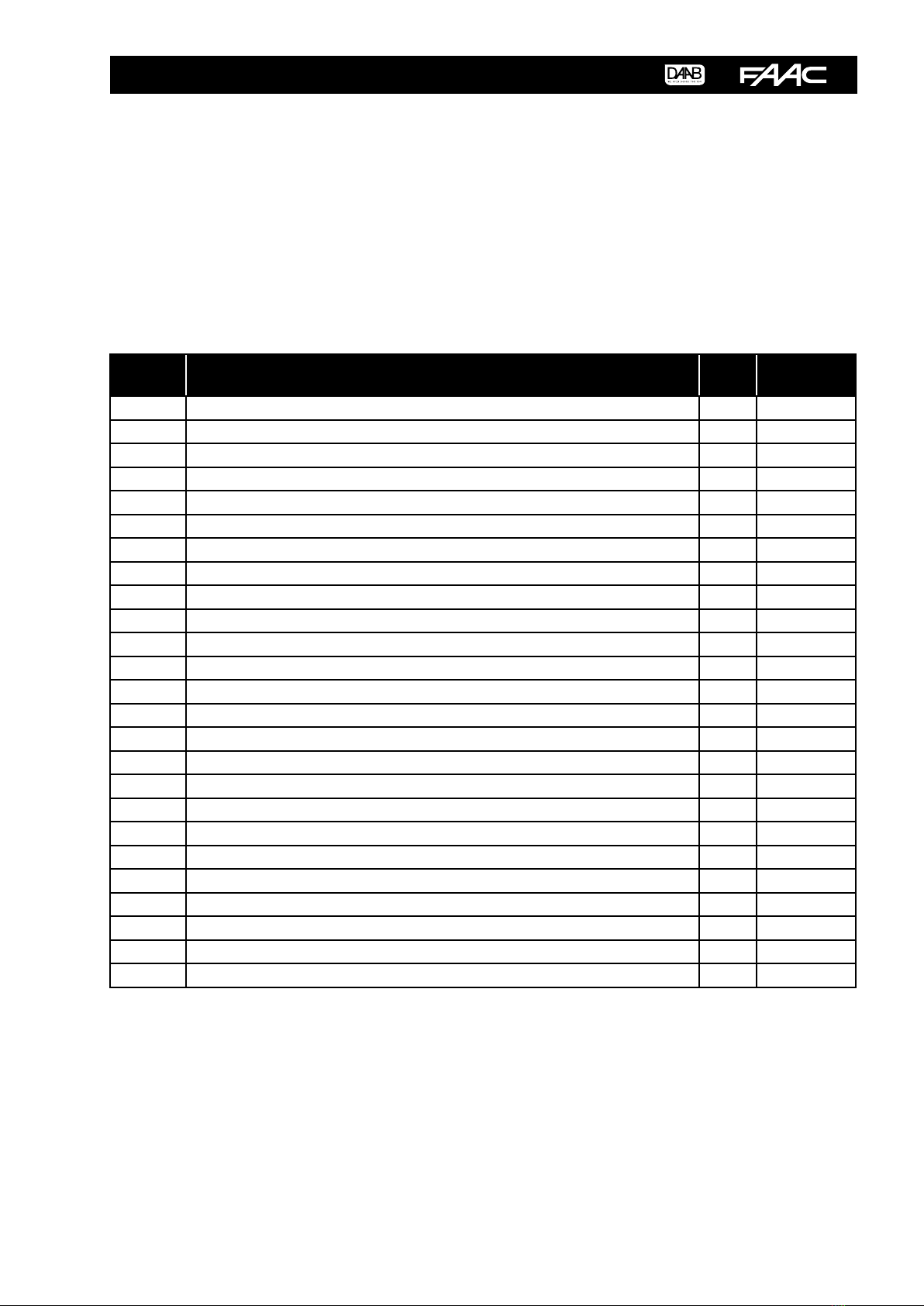

• Channel settings in the frequency converter

Channel

no. Description Fixed

value

Value to be

adjusted

00-03 used to display the output frequency during operation 1

01-00 used to set the maximum output frequency 70 Hz

01-03 used to set the low frequency 7,5 Hz

01-04 used to set the low frequency voltage 60 V

01-05 used to set the start frequency 1,5 Hz

01-06 used to set the start frequency voltage 40 V

01-09 used to set the acceleration time

01-10 Used to dene the retardation time

02-00 used to set the control method 0

02-01 used to set the start method 1

02-02 used to set the type of stop 1

02-04 used to block reversing 1

03-00 used to set the multifunction output 1

03-08 used to set the internal cooling fan 2

04-06 used to set the function of input MI4 2

04-05 used to set the function of input MI3 1

04-04 used to set the function of input MI1 0

* used to set the opening speed

05-00 used to set braking in the opening movement

05-01 used to set the closing speed

05-02 used to set braking in the closing movement

06-01 used to set the over-current protection 170

06-06 used to set the electronic overload relay 2

08-08 used to set the current limit for a speed increase 170

08-15 used to set the number of start attempts before an error message is generated 0

* = is is set using the arrow keys on the display when the frequency converter is in F XX mode. is setting does not use a

channel.