Contents

PWhat is a Dryer?........................................................................................................................................................ 2

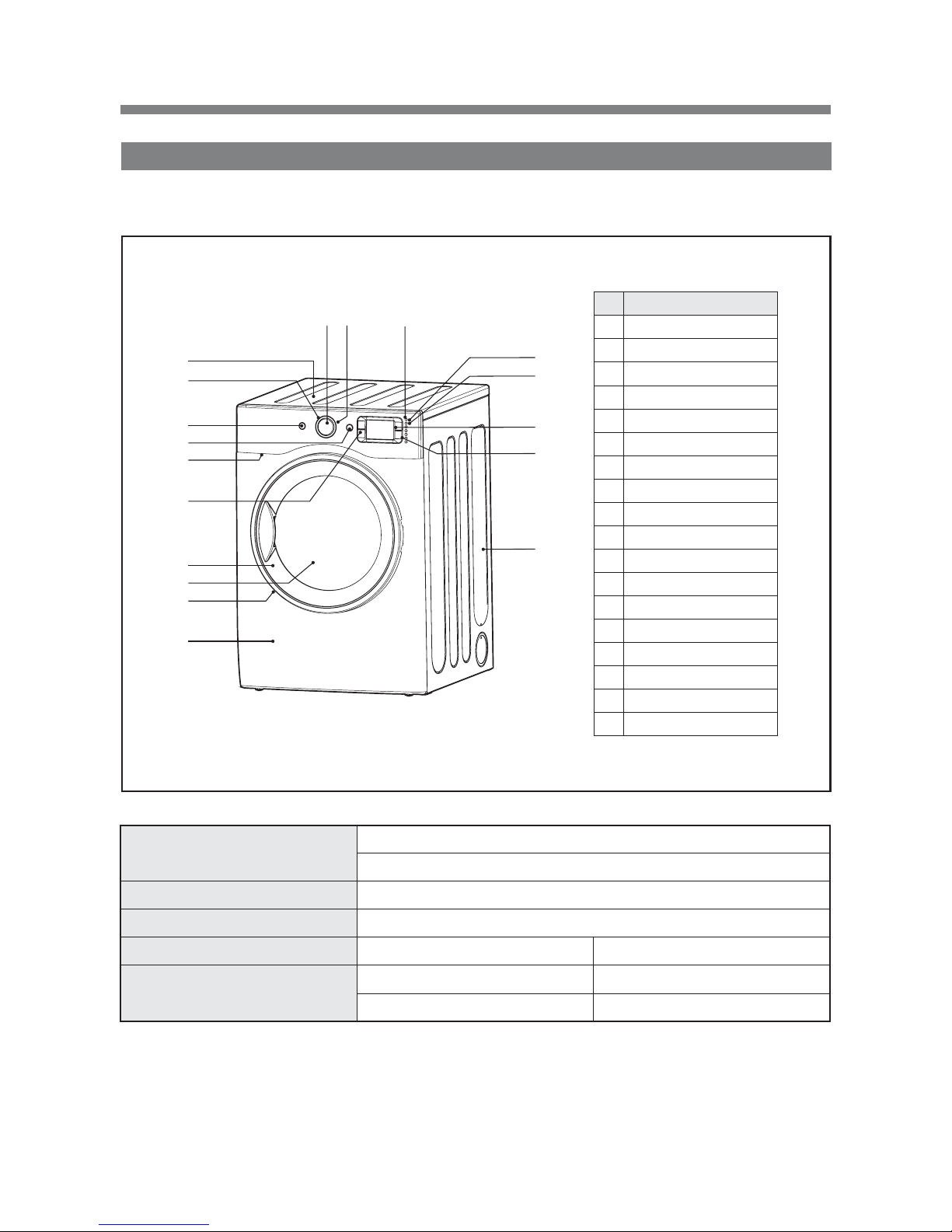

PDryer Specification .................................................................................................................................................... 4

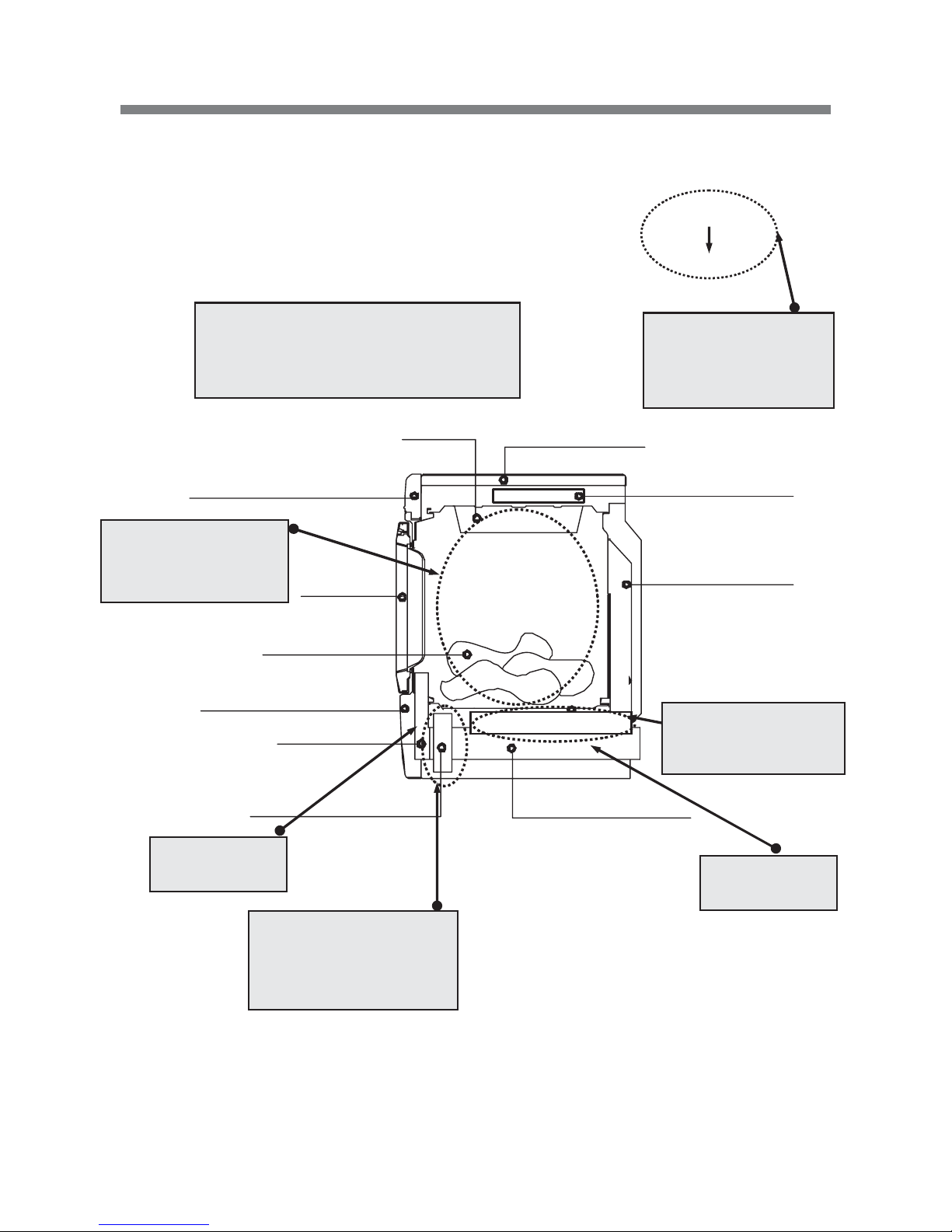

POperating Mechanism Diagram (Gas Type) ............................................................................................................ 5

POperating Mechanism Diagram (Electric Type) ....................................................................................................... 6

PMechanism by Ass’y (Electric Type)......................................................................................................................... 7

PMechanism by Ass’y (Gas Type).............................................................................................................................. 8

PParts List by Ass’y ..................................................................................................................................................... 9

PPCB Function Specification ................................................................................................................................... 23

PDrum Dryer Troubleshooter .................................................................................................................................... 37

PDryer Installation...................................................................................................................................................... 40

PElectrical Requirements For Electric Dryers........................................................................................................ ...41

PDryer Service Notices ............................................................................................................................................ 47

PElectric Parts List – Electric Clothes Dryer ............................................................................................................. 48

PElectric Parts List – Gas Clothes Dryer .................................................................................................................. 49

Thermostat Fan .........................................................................................................................................................................50

Thermostat Cut–Out..................................................................................................................................................................51

Thermostat Hi–Limit ..................................................................................................................................................................52

Lamp Assembly.........................................................................................................................................................................53

Switch Door ...............................................................................................................................................................................54

Heater Assembly .......................................................................................................................................................................55

Belt Switch (Switch Micro).........................................................................................................................................................56

Thermistor Fan ..........................................................................................................................................................................57

Motor Dryer................................................................................................................................................................................58

Igniter As....................................................................................................................................................................................60

Flame Sensor ............................................................................................................................................................................61

Thermostat Hi–Limit ..................................................................................................................................................................62

Thermostat Cut–Out..................................................................................................................................................................63

Valve Gas As.............................................................................................................................................................................64

PDismantling Method Per Dryer Ass'y

PANEL FRONT ASS’Y / PLATE TOP ASS'Y...........................................................................................................................65

CABINET FRONT ASS'Y..........................................................................................................................................................66

FRAME UPPER / SEPARATION OF LAMP,PCB MAIN CONNECTOR ................................................................................67

PCB MAIN / DUCT OUTLET ASS'Y.........................................................................................................................................68

SUPPORT DRUM FRONT ASS'Y / DRUM ASS'Y / PIPE EXHAUST....................................................................................69

COVER BACK / SUPPORT DRUM REAR ASS'Y...................................................................................................................70

MOTOR CONNECTOR ............................................................................................................................................................71

TERMINAL BLOCK...................................................................................................................................................................72

MOTOR ASS'Y..........................................................................................................................................................................73

HEATER ASS'Y / LAMP ASS'Y................................................................................................................................................75

FILTER DUST ASS'Y / HUMIDTY SENSOR ...........................................................................................................................76

DOOR ASS'Y.............................................................................................................................................................................77

GAS BURNER ASS'Y ...............................................................................................................................................................79