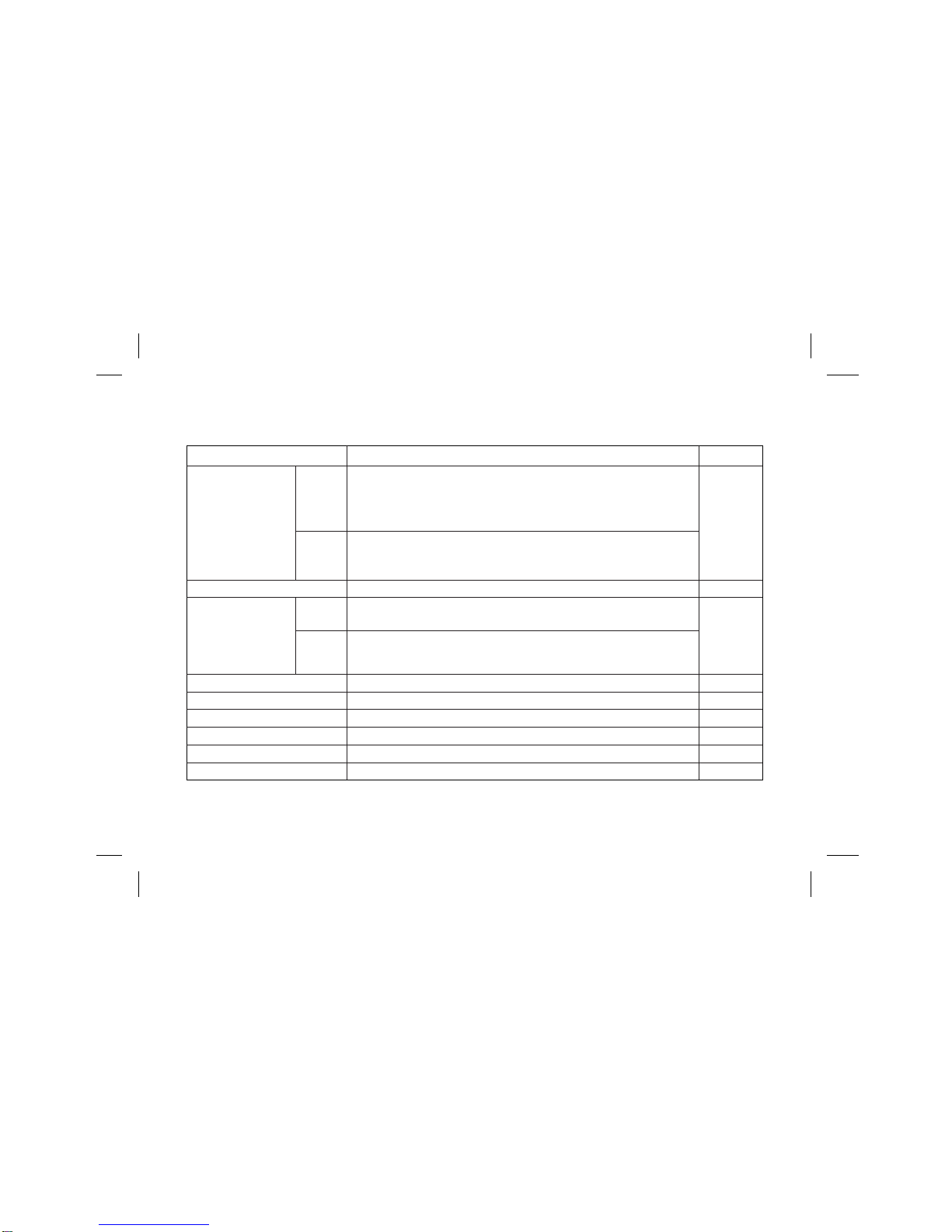

D1146 Primary filter:clean at every 5,000km,change at every 15,000km there

Change at every 20,000km. 166Page

Valve clearance Adjust at end of first 1,000km and every 20,000km there after. 171 Page

Air cleaner Clean at every 4,000km, change at every 12,000km there after. 176 Page

Transmission oil Change at end of first 5,000km and every 20,000km there after. 178 Page

Rear axle oil Change at end of first 5,000km and every 20,000km there after. 179 Page

Power steering oil Change at end of first 1,000km and every 24,000km there after. 180 Page

Power steering filter Change at end of first 1,000km and every 24,000km there after. 182 Page

IMPORTANT SERVICE ACTIVITIES

ҧAny failure resulting from a lack of normal maintenance as the maintenance service chart in this manual is not covered

by warranty.

CHECK ITEMS CHECK AND SERVICE INTERVALS PAGE

Engine oil 163 Page

Change : At end of first 1,000km,

long distance : every 30,000km

short distance : every 20,000km

D1146Ti

DE08TiS

DE12/T/Ti/TiS

Fuel filter

D1146

D1146Ti

DE12

DE12T

DE12Ti

Primary filter : clean at every 5,000km,

change at every 15,000km there after.

secondary filter : change at every 5,000km.

Engine oil filter Change with engine oil 164Page

DE08TiS

DE12TiS

Change : At end of first 1,000km,

High-speed, long distance : every 15,000km

In city, short distance : every 10,000km