1

TABLE OF CONTENTS

SAFETY & PRECAUTIONS ............................................................................................. 2

EXTERNAL VIEWS ........................................................................................................ 4

FRONT VIEWS FUNCTION ...................................................................................................................4

REAR VIEWS FUNCTION .....................................................................................................................5

ELECTRICAL ADJUSTMENT ........................................................................................... 6

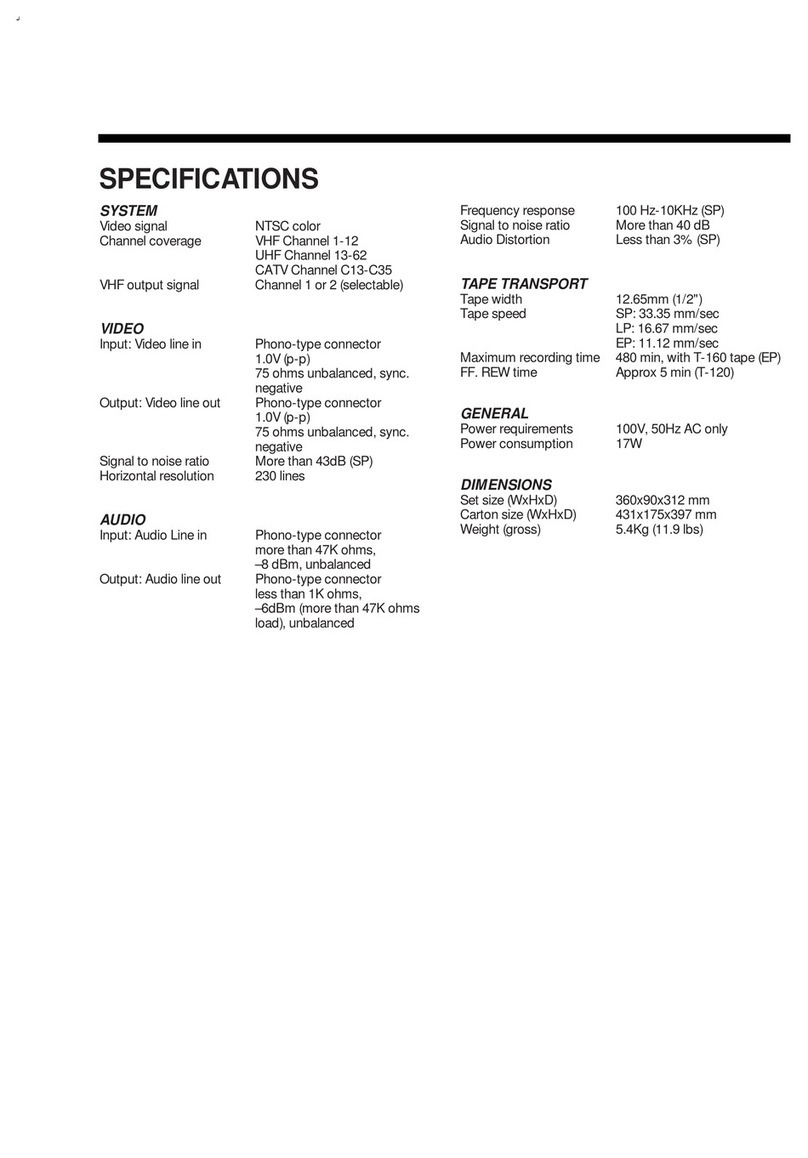

SPECIFICATIONS ....................................................................................................... 12

TIMELAPSE REC/PB SPEED CHART

................................................................................ 13

CIRCUIT OPERATION .................................................................................................. 14

VOLTAGE CHART ....................................................................................................... 22

CIRCUIT DIAGRAM ..................................................................................................... 28

CONNECTION DIAGRAM ..................................................................................................................28

POWER CIRCUIT DIAGRAM ................................................................................................................29

SYSCON CIRCUIT DIAGRAM ..............................................................................................................30

VIDEO CIRCUIT DIAGRAM .................................................................................................................31

PRE-AMP CIRCUIT DIAGRAM .............................................................................................................32

OSD CIRCUIT DIAGRAM ....................................................................................................................33

AUDIO CIRCUIT DIAGRAM .................................................................................................................34

LOGIC CIRCUIT DIAGRAM .................................................................................................................35

TERMINAL CIRCUIT DIAGRAM ............................................................................................................36

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW ........................................... 37

PCB MAIN .........................................................................................................................................37

PCB UNION .......................................................................................................................................38

DISASSEMBLY ............................................................................................................. 39

PANEL FRONT ASS’Y ...........................................................................................................................39

SET TOTAL ASS’Y .................................................................................................................................40

PACKING ASS’Y .................................................................................................................................41

ELECTRICAL PARTS LIST ............................................................................................... 42

TROUBLE SHOOTING FLOW CHART ............................................................................. 1

POWER CIRCUIT ................................................................................................................................1

SERVO-SYSCON CIRCUIT ...................................................................................................................3

VIDEO CIRCUIT .................................................................................................................................11

AUDIO CIRCUIT .................................................................................................................................15

u-COM PORT DESCRIPTION ....................................................................................... 18

APPENDIX(Appendix is provided only by internet http://svc.dwe.co.kr)