iom-clim-cf-engwww.clima-ex.com

9

Figure 6. Three or more units, side by side

Case 4. Open protection walls

Decorative walls are often used to help conceal a unit, either on

the ground or on the roof. Whenever possible, design these walls

so that the combination of their open area and distance to the unit

does not require a performance adjustment.

If the percentage of wall openness is less than recommended for

the distance to the unit, it should be considered a solid wall. The

wall height is assumed to be equal to or less than the height of the

unit when mounted on its base bracket.

If the wall height is greater than the unit height, refer to Case 5:

Pit Installation for performance adjustment factors. The distance

from the sides of the unit to the side walls must be sufficient for

service, such as opening the control panel doors.

In the case of uneven wall separation, the distance from the unit

to each wall can be averaged as long as no distance is less than

4 feet. Values are based on walls on all four sides.

Case 5. Pit installation

Pit installations can cause operating problems due to recirculation

and air restriction and require that sufficient air separation be

provided, safety requirements be met, and service access be

provided. A solid wall surrounding a unit is substantially a pit and

this datum should be used. Sometimes a steel grating is used to

cover a pit to prevent accidental falls or trips into the pit.

The grille material and installation design should be strong

enough to prevent such accidents, but should provide plenty of

open area to avoid recirculation problems.

Have the Clima Flex sales representative review the installation

of any pit prior to installation to ensure that it has sufficient airflow

characteristics and is approved by the facility design engineer to

avoid the risk of an accident.

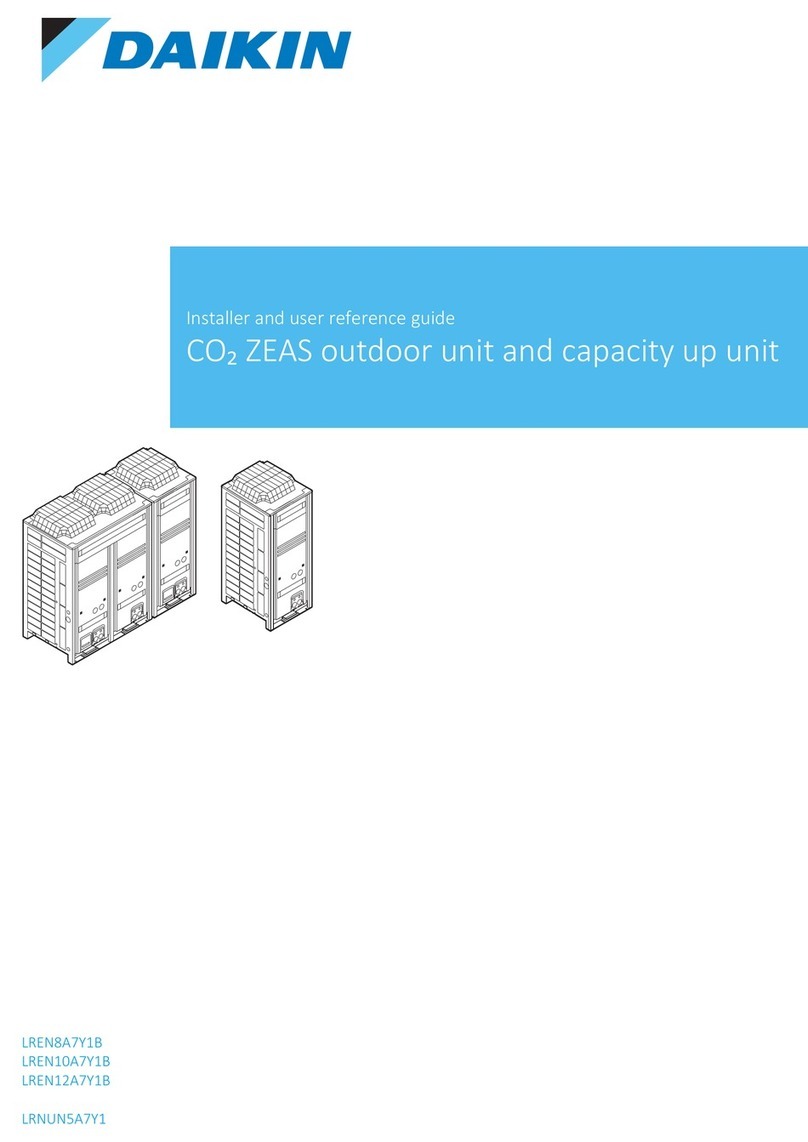

Figure 7. Pit installation

! CAUTION !

To prevent damage to the evaporator and possible failure of

the chiller, a supply filter is required in the inlet water piping

that connects to this evaporator. This filter must be installed

prior to operation of the chilled liquid pumps.

Field-installed water piping for the chiller should include:

• A cleanable filter installed at the water inlet to the evaporator

to remove debris and impurities before they reach the

evaporator. Install the cleanable filter within 1,500 mm tubing

length from the evaporator inlet connection and downstream

of any solder connections (no solder connections between

the filter and evaporator). CLIM models 7.5 - 62.5 require

a filter with perforations no larger than 1.6 mm (0.063”) in

diameter. For more information, refer to the inlet strainer

guidelines on page 10-11.

• A water flow switch should be installed in the horizontal

piping of the supply water line (evaporator outlet) to prevent

evaporator freezing under low or no flow conditions. The flow

switch can be ordered as a factory installed option, as a field

installed kit, or can be supplied and installed in the field. See

page 12 for more information.

• Piping for units with brazed plate evaporators must have

a drain and vent connection at the bottom of the bottom

connection piping and at the top of the top connection piping,

respectively, see Figure 8.

• These evaporators do not have drain or vent connections due

to their construction. Purge air from the water system prior to

unit start-up to provide adequate flow through the evaporator.

• A suitable pipe support, separate from the unit, to eliminate

weight and stress on fittings and connections.

• An expansion tank and regulating valve to maintain water

pressure.

• Suitable mechanical connections. All evaporators have.

• OGS type grooved water connections (adhering to AWWA

C606) optionally with flanges. PVC piping should not be used.

! WARNING !

Polyolester oil, commonly known as POE oil, is a synthetic oil used in many refrigeration systems and is present in this Clima Flex

product. POE oil, if it ever comes in contact with PVC/CPVC, will coat the inside wall of the PVC/CPVC pipe causing environmental

stress fractures. Although there is no PVC/CPVC pipe in this product, keep this in mind when selecting piping materials for your

application as system failure and property damage could occur. Consult the pipe manufacturer’s recommendations to determine

suitable pipe applications.