9

IOM 1264-4 WWW.DAIKINAPPLIED.COM

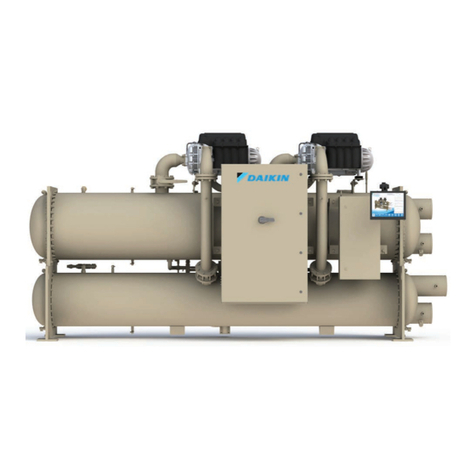

INSTALLATION

CAUTION

When common piping is used for both building heating and

cooling modes, care must be taken to provide that water

owing through the evaporator cannot exceed 109.4°F (43°C).

Water this hot can damage controls or cause the relief valve to

discharge refrigerant.

Piping must be supported to eliminate weight and strain on the

ttings and connections. Chilled water piping must be adequately

insulated.

Inlet Strainer Guidelines

An inlet water strainer must be installed in the chilled water piping

before the evaporator inlet. Two paths are available to meet this

requirement:

1. A eld-installed kit shipped loose with the unit that consists of:

• Y-type area strainer with 304 stainless steel perforated

basket, groove pipe connections and strainer cap

• Extension pipe with two Schrader ttings that can be used

for a pressure gauge and thermal dispersion ow switch.

The pipe provides sucient clearance from the evaporator

for strainer basket removal

• ½-inch blowdown valve

• Two grooved clamps

2. A eld-supplied strainer that meets specication and

installation requirements of this manual on www.DaikinApplied.

com.

Inlet and outlet connections are clearly marked on the unit and

also appear on the dimension drawings. Drain connections

should be provided at all low points in the system to permit

complete drainage. Air vents should be located at the high points

in the system to purge out air. A vent connection, located on top

of the evaporator vessel, permits the purging of air out of the

evaporator. Air purged from the water system prior to unit start-up

provides adequate ow through the vessel and prevents safety

cutouts on the freeze protection. System pressure should be

maintained by using a properly sized expansion tank.

Pressure gauges should be installed in the inlet and outlet water

lines to the evaporator. Pressure drop through the evaporator

should be measured to calculate proper gpm (L/s) as specied in

the Pressure Drop tables.

Source water piping may have to be insulated (depending on its

temperature) to reduce heat loss and prevent condensation if

cold water is used. If cooling tower water is used, insulation may

not be necessary. Complete unit and system leak tests should

be performed prior to insulating the water piping. Insulation with

a vapor barrier is recommended. If the vessel is insulated, the

vent and drain connections must extend beyond the proposed

insulation thickness for accessibility. If the unit operates year-

round, or if the system is not drained for the winter, the chilled

water piping exposed to outdoor ambient should be protected

against freezing by wrapping the lines with a heater cable.

System Water Volume

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling usually

exists when the building load falls below the minimum chiller

plant capacity or on close-coupled systems with very small

water volumes. Some of the things the designer should consider

when looking at water volume are the minimum cooling load, the

minimum chiller plant capacity during the low load period and the

desired cycle time for the compressors.

A storage tank may have to be added to the system to reach the

recommended system volume. Refer to AG 31-003 for method of

calculating “Minimum Chilled Water Volume”.

The water quality provided by the owner/occupant/operator/user

to a chiller system should minimize corrosion, scale buildup,

erosion, and biological growth for optimum eciency of HVAC

equipment without creating a hazard to operating personnel or

the environment. Strainers must be used to protect the chiller

systems from water-borne debris. Daikin Applied will not be

responsible for any water-borne debris damage or water side

damage to the chiller heat exchangers due to improperly treated

water.

Water systems should be cleaned and ushed prior to chiller

installation. Water testing and treatment should be veried

during initial chiller installation/commissioning and maintained on

a continuous basis by water treatment professionals (see Limited

Product Warranty).

CAUTION

The improper use of detergents, chemicals, and additives in the

chiller system water may adversely aect chiller performance

and potentially lead to repair costs not covered by warranty.

Any decision to use these products is at the discretion of the

owner/occupant/operator/user as such they assume full liability/

responsibility for any damage that may occur due to their use.

Vessel Drains at Startup

The unit is drained of water at the factory. Drain plugs for each

vessel head are shipped separately in the control box. Units are

shipped with the drain plug in the top water box vent hole and no

plug in the bottom drain hole. Install the bottom drain plugs prior

to lling the vessel with uid. See Figure 5.