IOM 1206-7 • TRAILBLAZER™MODEL AGZ CHILLERS 4 www.DaikinApplied.com

InsTallaTIon and applICaTIon InformaTIon

Operating and Standby Limits

Table 1: Operating Limits

Maximum standby ambient temperature 131°F (55°C)

Maximum operating ambient temperature 105°F (41°C)

-with optional high ambient package (see information under High Ambient Operation) 125°F (52°C)

Minimum operating ambient temperature (standard control) 32°F (0°C)

Minimum operating ambient temperature (with optional low-ambient control) -10°F (-23°C)

Leaving chilled water temperature 40°F to 65°F (4°C to 18°C)

Leaving chilled uid temperatures (with anti-freeze) - Note that in cases of high ambient

temperature, the lowest leaving water temperature settings may be outside of the chiller

operating envelope; consult Daikin Tools to ensure chiller is capable of the required lift.

15°F to 65°F (-9°C to 18°C)

Operating chilled water delta-T range 6°F to 16°F (3.3°C to 8.9°C)

Maximum evaporator operating inlet uid temperature 81°F (27°C)

Maximum evaporator non-operating inlet uid temperature 100°F (38°C)

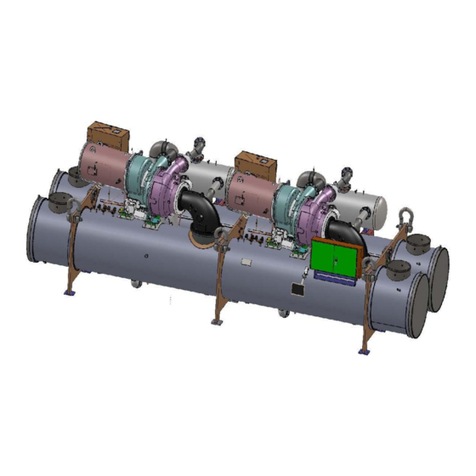

Unit Placement

Trailblazer™units are for outdoor applications and can be

mounted either on a roof or at ground level. For roof mounted

applications, install the unit on a steel channel or I-beam

frame to support the unit above the roof. For ground level

applications, install the unit on a substantial base that will not

settle. Use a one-piece concrete slab with footings extended

below the frost line. Be sure the foundation is level within 0.5”

(13 mm) over its length and width. The foundation must be

strong enough to support the unit weight - see “Dimensions

and Weights - Packaged Units” on page 20.

Service Clearance

Sides

• 30-70 Ton Models: Minimum of 4 feet (1.2 meters)

• 75-240 Ton Models: It is highly recommended to

provide a minimum of 8 feet (2.4 meters) on one side to

allow for coil replacement. Coils can be removed from

the top, allowing a minimum of 4 feet (1.2 meters) of

side clearance; however, the unit performance may be

derated.

Control Panel End

• All Models: Minimum of 4 feet (1.2 meters)

Opposite Control Panel End

• 30-70 Ton Models with Microchannel Coils: Minimum

of 7.5 feet (2.3 meters)

• 75-180 Ton Models: Minimum of 4 feet (1.2 meters)

• 190-240 Ton Models: Minimum of 8 feet (2.4 meters) for

evaporator removal

Figure 3: Service Clearance

Spacing Requirements

Sufcient clearance must be maintained between the unit

and adjacent walls or other units to allow the required unit air

ow to reach the coils. Failure to do so will result in a capacity

reduction and an increase in power consumption. No solid

obstructions are allowed above the unit at any height, see page

7for details.

Graphs on the following pages give the minimum clearance

for different types of installations and also capacity reduction

and power increase if closer spacing is used. The clearance

requirements shown are a general guideline and cannot

account for all scenarios. Such factors as prevailing winds,

additional equipment within the space, design outdoor air

temperature, and numerous other factors may require more

clearance than what is shown.

Minimum = 4 ft (1.2 m)

Minimum = 4 ft (1.2 m)

Minimum = 4 ft

(1.2 m)

Minimum = 7.5 ft (2.3 m)

for models 030-070

with Microchannel Coils

Control Panel

Minimum = 4 ft (1.2 m)

for models 075-180

075-240 Ton Models: 8ft (2.4 m) recommended on one side

Minimum = 8 ft (2.4 m)

for models 190-240