3

NOTE: The nameplate for modular units contains only the first

two digits in the model number. For example, 315A and 315B

nameplates read 31A and 31B.

Table 1 — Modular Unit Combinations

NOTE: An “A” in the model number indicates the design series.

Conventions Used in This Manual — The follow-

ing conventions for discussing configuration points for the

local display (scrolling marquee or Navigator™ accessory)

will be used in this manual.

Point names will be written with the mode name first, then

any sub-modes, then the point name, each separated by an

arrow symbol (. Names will also be shown in bold

and italics. As an example, the Lead/Lag Circuit Select Point,

which is located in the Configuration mode, Option sub-mode,

would be written as Configuration OPTNLLCS.

This path name will show the user how to navigate through

the local display to reach the desired configuration. The user

would scroll through the modes and sub-modes using the

and keys. The arrow symbol in the path name repre-

sents pressing to move into the next level of the

menu structure.

When a value is included as part of the path name, it will be

shown at the end of the path name after an equals sign. If the

value represents a configuration setting, an explanation will

be shown in parenthesis after the value. As an example,

ConfigurationOPTNLLCS = 1 (Circuit A leads).

Pressing the and keys simultaneously

will scroll an expanded text description of the point name or

value across the display. The expanded description is shown in

the local display tables but will not be shown with the path

names in text.

The CCN (Carrier Comfort Network®) point names are also

referenced in the local display tables for users configuring the

unit with CCN software instead of the local display. The CCN

tables are located in Appendix B of the manual.

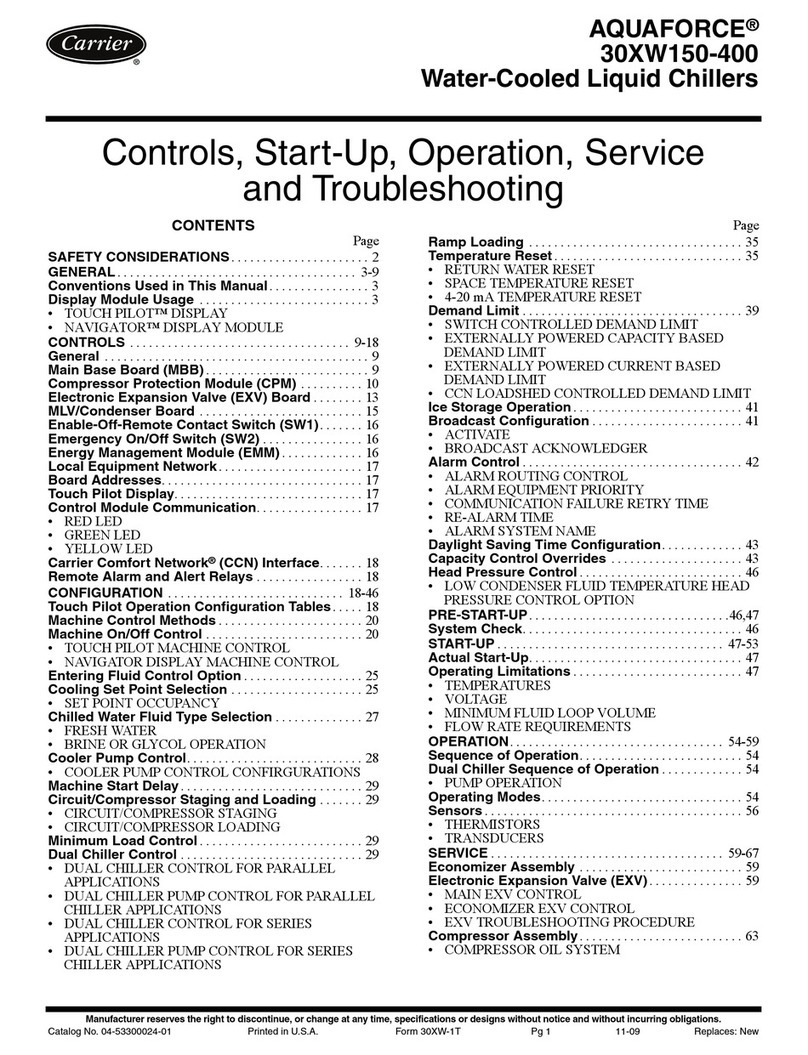

Basic Control Usage

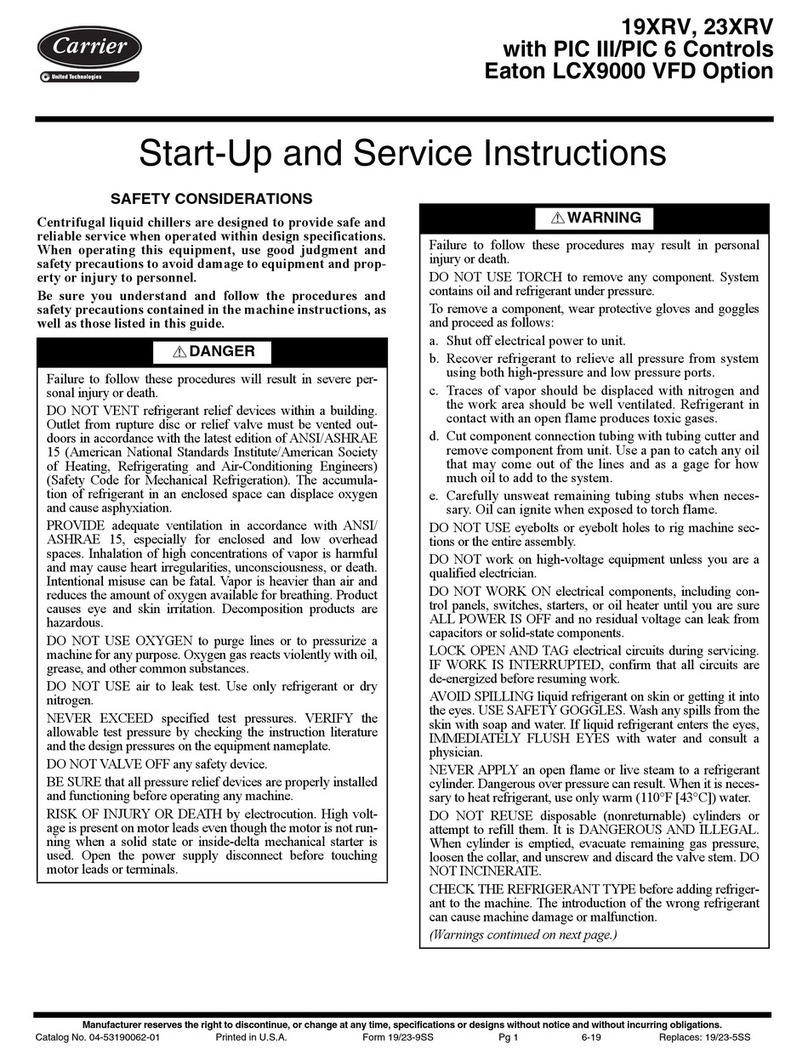

SCROLLING MARQUEE DISPLAY — The scrolling mar-

quee display is the standard interface display to the ComfortLink

Control System for 30RB units. The display has up and down

arrow keys, an key, and an key. These

keys are used to navigate through the different levels of the

display structure. Press the key until the highest

operating level is displayed to move through the top 11 mode

levels indicated by LEDs (light-emitting diodes) on the left side

of the display. See Fig. 1.

Once within a mode or sub-mode, pressing the

and keys simultaneously will put the scrolling

marquee display into expanded text mode where the full mean-

ing of all sub-modes, items and their values can be displayed

for the current selection. Press the and

keys to return the scrolling marquee display to its default menu

of rotating display items (those items in Run Status

VIEW).

In addition, the password will be disabled, requiring that it be

entered again before changes can be made to password

protected items. Press the key to exit out of the ex-

panded text mode.

NOTE: When the Language Selection (Configuration

DISP

LANG), variable is changed, all appropriate display

expansions will immediately change to the new language. No

power-off or control reset is required when reconfiguring

languages.

When a specific item is located, the item name alternates

with the value. Press the key at a changeable item

and the value will be displayed. Press again and the

value will begin to flash indicating that the value can be

changed. Use the up and down arrow keys to change the value,

and confirm the value by pressing the key.

Changing item values or testing outputs is accomplished in

the same manner. Locate and display the desired item. Press

so that the item value flashes. Use the arrow keys to

change the value or state and press the key to accept

it. Press the key to return to the next higher level of

structure. Repeat the process as required for other items.

Items in the Configuration and Service Test modes are pass-

word protected. The words ‘PASS’ and ‘WORD’ will alternate

on the display when required. The default password is 0111.

Press and the 1111 password will be displayed. Press

again and the first digit will begin to flash. Use the

arrow keys to change the number and press to accept

the digit. Continue with the remaining digits of the password.

The password can only be changed through CCN operator in-

terface software such as ComfortWORKS®, ComfortVIEW™

and Service Tool.

See Table 2 and Appendix A for further details.

ACCESSORY NAVIGATOR™ DISPLAY MODULE —

The Navigator module provides a mobile user interface to the

ComfortLink™ control system, which is only available as a

field-installed accessory. The display has up and down arrow

keys, an key, and an key. These keys are

used to navigate through the different levels of the display

structure. Press the key until ‘Select a Menu Item’

is displayed to move through the top 11 mode levels indicated

by LEDs on the left side of the display. See Fig. 2.

Once within a Mode or sub-mode, a “>” indicates the cur-

rently selected item on the display screen. Pressing the

and keys simultaneously will put the Nav-

igator module into expanded text mode where the full meaning

of all sub-modes, items and their values can be displayed. Press-

ing the and keys when the display says

‘Select Menu Item’ (Mode LED level) will return the Navigator

module to its default menu of rotating display items (those items

UNIT SIZE MODULE A MODULE B

30RBA315 30RBA160 30RBA160

30RBA330 30RBA170 30RBA160

30RBA345 30RBA170 30RBA170

30RBA360 30RBA190 30RBA170

30RBA390 30RBA190 30RBA190

Run Status

Service Test

Temperature

Pressures

Setpoints

Inputs

Outputs

Configuration

Time Clock

Operating Modes

Alarms

Alarm Status

ENTER

MODE

ESCAPE

Fig. 1 — Scrolling Marquee Display