IOM 1274-3 • CENTRIFUGAL WATER CHILLERS 10 www.DaikinApplied.com

WARNING

Polyolester Oil, commonly known as POE oil is a synthetic

oil used in many refrigeration systems, and is present in this

Daikin Applied product. POE oil, if ever in contact with PVC/

CPVC, will coat the inside wall of PVC/CPVC pipe causing

environmental stress fractures. Although there is no PVC/

CPVC piping in this product, please keep this in mind when

selecting piping materials for your application, as system

failure and property damage could result. Refer to the pipe

manufacturer’s recommendations to determine suitable

applications of the pipe.

CAUTION

connections:

1. Remove the solid-state temperature sensor,

switches from the wells to prevent damage to those

components.

2. Properly ground the unit or severe damage to the

MicroTech®unit controller can occur.

NOTE:

performed on a vessel shell or tube sheet.

The water heads can be interchanged (end for end) so that

the water connections can be made at either end of the unit.

If this is done, use new head gaskets and relocate the control

sensors.

Field installed water piping to the chiller must include:

• air vents at the high points.

• a cleanable water strainer upstream of the evaporator

and condenser inlet connections.

•

condenser. Flow switches, thermal dispersion switches,

or Delta-P switches can be used. Note that thermal

series with the ones already provided. Connect additional

discussed on page 69.

• water pressure gauge connection taps and gauges at the

inlet and outlet connections of both vessels for measuring

water pressure drop.

•

chiller must be capable of draining the water from the

evaporator or condenser without draining the complete

system.

• Piping must be supported to eliminate weight and strain

• Chilled water piping must be adequately insulated.

• thermometers at the inlet and outlet connections of both

vessels.

CAUTION

When common piping is used for both building heating and

cooling modes, care must be taken to provide that water

this hot can damage controls or cause the relief valve to

discharge refrigerant.

NOTE:

equipped with a shell and tube evaporator with

carbon steel shell and copper tubes. The water or

the heat exchangers must be clean and non-corrosive

to the standard materials of construction. Daikin

Applied makes no warranty as to the compatibility

void the equipment warranty. If the compatibility of

is in question, a professional corrosion consultant

should administer the proper testing and evaluate

compatibility.

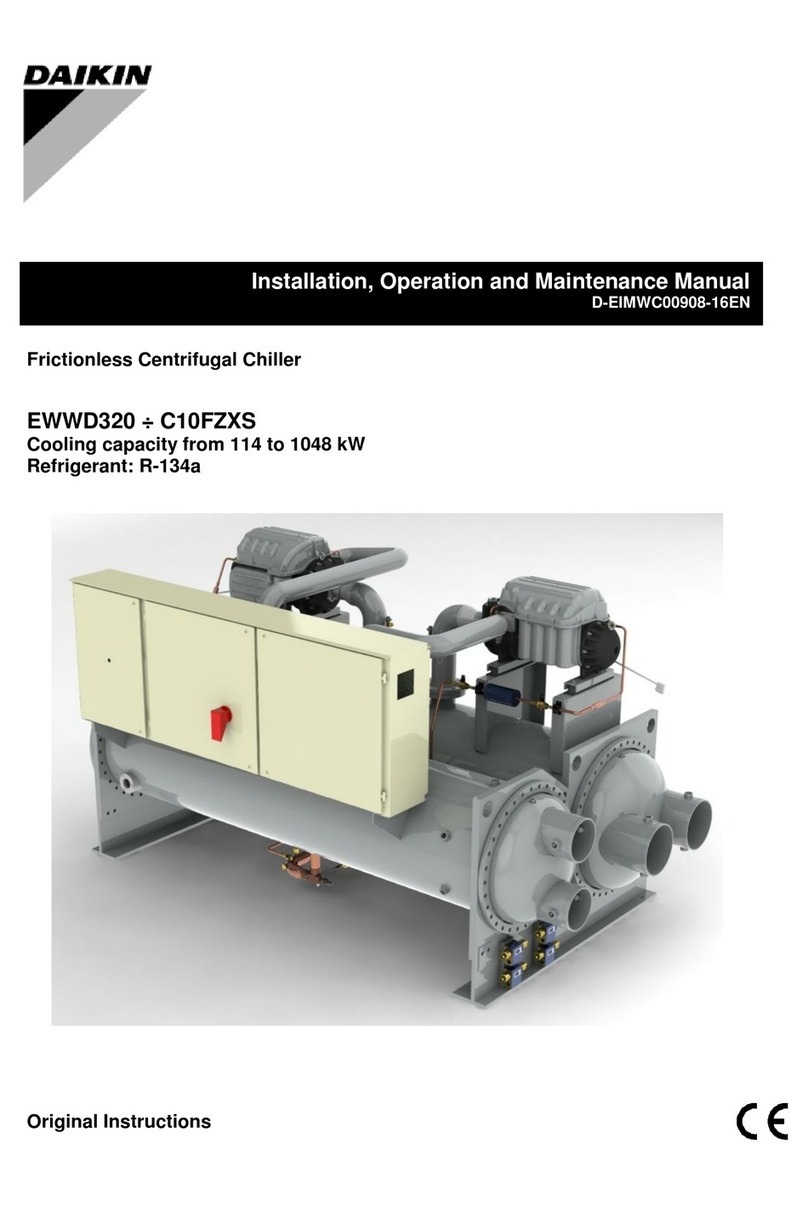

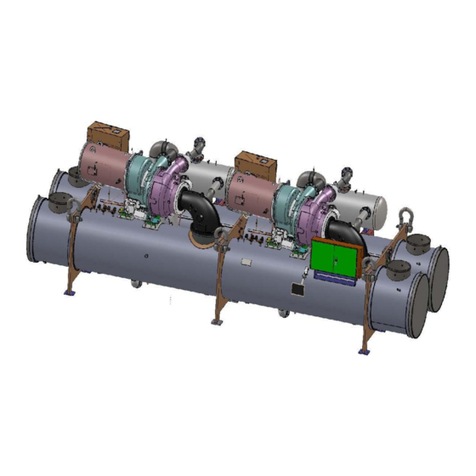

Heat Recovery Condenser

Connections

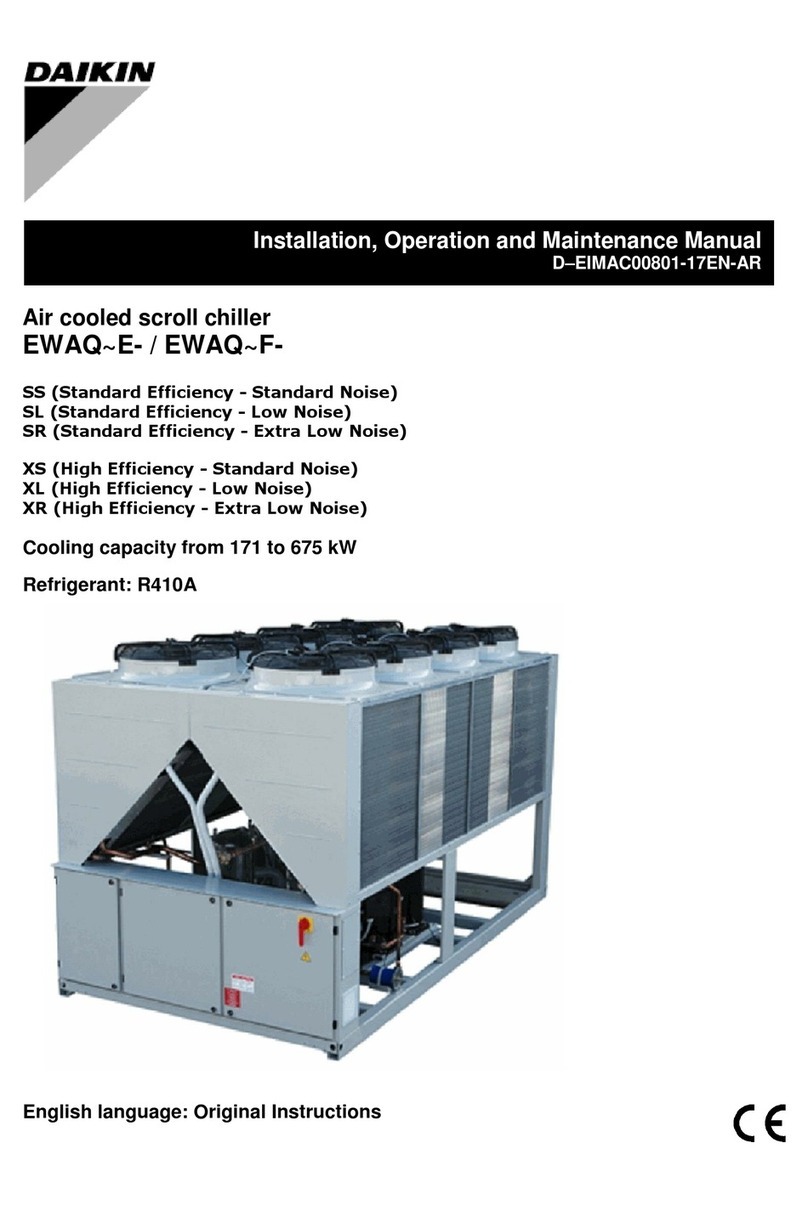

The tower connections on heat

recovery units are always the

inboard pair of connections.

In the image to the left, the

condenser connections are

the front of the unit (Unit Control

Panel and Interface Panel side),

so in this case, the right-hand

condenser connections would be

for the tower. If the condenser

connections were on the other

connections would be the left-

hand pair of connections.

and care must be used to avoid sources that can cause

corrosion, fouling, or accumulation of debris in the heat

exchanger. For open water loop applications, an intermediate

heat exchanger between the source water and unit evaporator

may be desirable.

Water Quality Guidelines

The water quality provided by the owner/occupant/operator/

user to a chiller system should minimize corrosion, scale

of HVAC equipment without creating a hazard to operating

personnel or the environment. Strainers must be used to

protect the chiller systems from water-borne debris. Daikin

Applied will not be responsible for any water-borne debris