2

The data inside this manual are not binding and they can be modified by the manufacturer without notice. All rights reserved.

NPC 015 TO 230

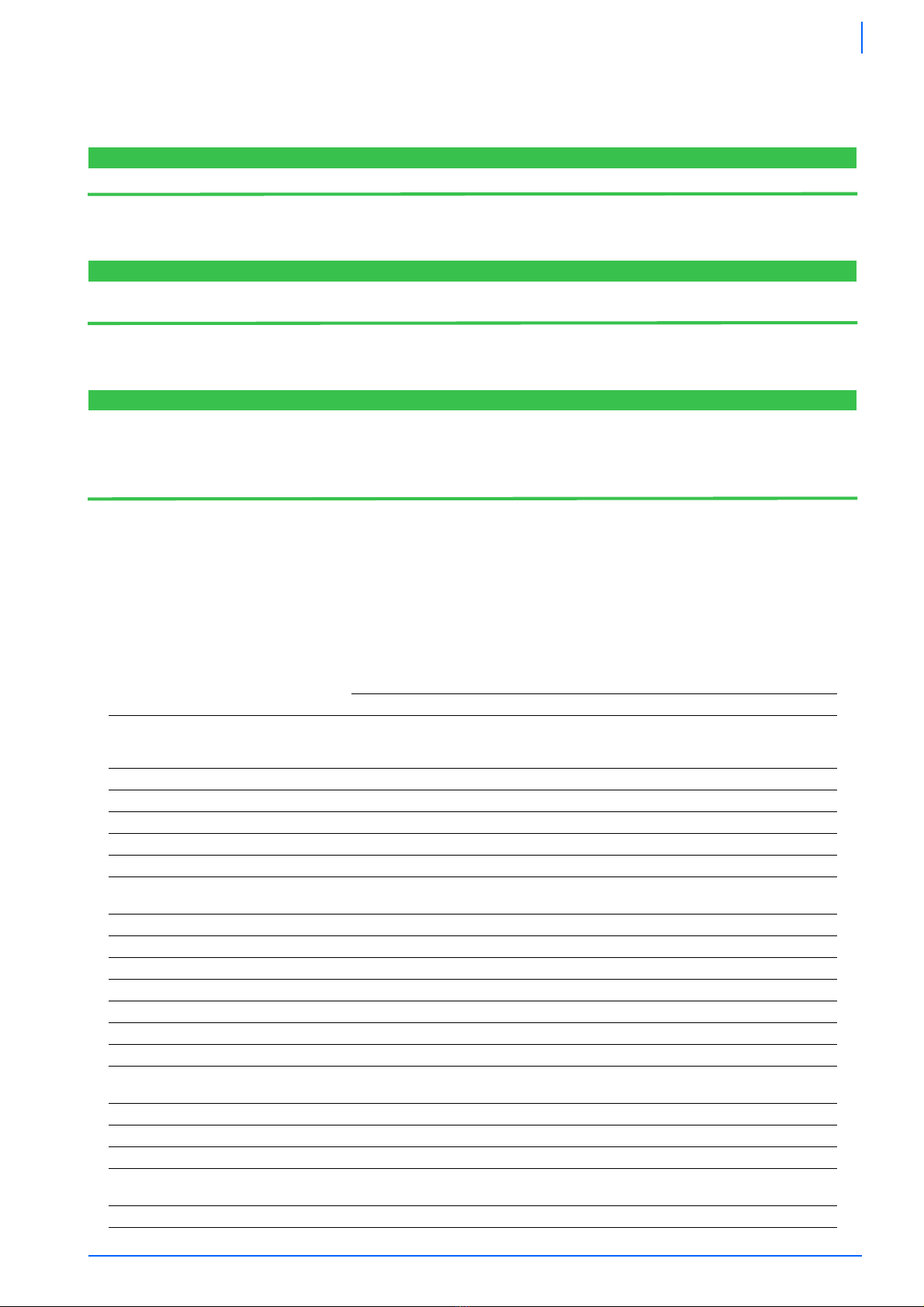

7.5 Displaying during an alarm......................................................................................................22

7.5.1 Alarm icons ..............................................................................................................................................23

7.6 How to silence the buzzer ........................................................................................................23

7.7 First start up..............................................................................................................................23

7.8 Programming by keyboard .......................................................................................................23

7.8.1 Access to “Pr1” parameters (User level) ................................................................................................23

7.8.2 How to modify a parameter’s value .........................................................................................................23

7.9 Values displayed ......................................................................................................................24

7.10 Unit switching on / off .............................................................................................................24

7.11 How to put the unit in stand-by................................................................................................24

7.12 Function menu (

*

button) ......................................................................................................25

7.12.1 Access to Function menu ..........................................................................................................................25

7.12.2 Exit Function menu ..................................................................................................................................25

7.12.3 How to display the alarms “ALrM” .........................................................................................................25

7.12.4 How to reset an alarm “rSt” ....................................................................................................................25

7.12.5 How to display the alarm historic “ALoG” .............................................................................................25

7.12.6 How to reset the alarm history “ArSt” ....................................................................................................25

7.12.7 Displaying the operating hours of loads “C1Hr - C2Hr - PFHr” ..........................................................26

7.13 Other functions by keyboard ....................................................................................................26

7.13.1 How to display the Set Point ....................................................................................................................26

7.13.2 How to modify the Set Point .....................................................................................................................26

7.14 Compressors unloading function..............................................................................................26

7.15 Probe key..................................................................................................................................26

O

THER

COMPONENTS

SETTING

....................................................................................................................27

8.1 Compressor integral protection (PI).........................................................................................27

8.2 Refrigerant high and low pressure switches.............................................................................27

8.3 Compressor operation ..............................................................................................................27

8.3.1 Compressor regulation graphic in Chiller mode .....................................................................................27

8.4 Fan speed regulation.................................................................................................................28

8.5 Level sensor..............................................................................................................................28

O

PERATION

AND

MAINTENANCE

..................................................................................................................29

9.1 Operation..................................................................................................................................29

9.2 Maintenance .............................................................................................................................29

9.3 Unit access................................................................................................................................29

9.4 Emptying the process water circuit ..........................................................................................30

9.5 Maintenance schedule ..............................................................................................................30

T

ROUBLE

SHOOTING

.....................................................................................................................................31

S

ETTING

TABLES

...........................................................................................................................................35

11.1 Parameter setting......................................................................................................................35

11.1.1 Thermoregulation parameters .................................................................................................................35

11.1.2 Configuration parameters ........................................................................................................................35

11.1.3 Dymanic set point parameters (NOT ENABLED FUNCTION) ..............................................................36

11.1.4 Energy Saving parameters (NOT ENABLED FUNCTION) ....................................................................36

11.1.5 Compressor parameters ...........................................................................................................................36

11.1.6 Fan parameters ........................................................................................................................................36

11.1.7 Antifreeze support resistance parameters ................................................................................................36

11.1.8 Defrost parameters (NOT ENABLED FUNCTION) ................................................................................36

11.1.9 Alarm parameters .....................................................................................................................................36

11.1.10LASER parameters (NOT ENABLED FUNCTION) ................................................................................36

ALARMS

..........................................................................................................................................................37

12.1 Alarm codes and actions ..........................................................................................................37

12.2 Outlet blocking.........................................................................................................................40