Daikin DRG0361DL00001S Operating instructions

Other Daikin Heat Pump manuals

Daikin

Daikin FHC71KVE9 User manual

Daikin

Daikin Altherma 3 WS User manual

Daikin

Daikin FTXR28EV1B9 User manual

Daikin

Daikin Altherma 3 H HT Series User manual

Daikin

Daikin Altherma 3 H HT F+W Product information sheet

Daikin

Daikin EHVH04S18CA User manual

Daikin

Daikin VRV HXY48TAVJU Dimension Guide

Daikin

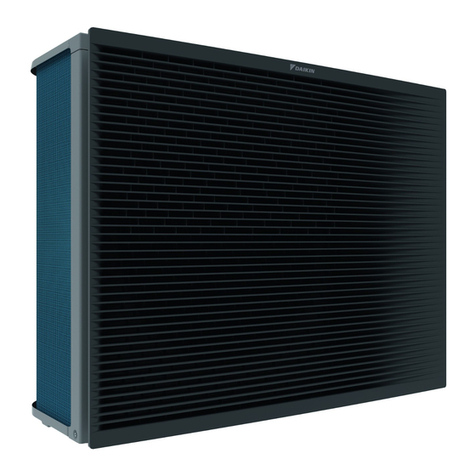

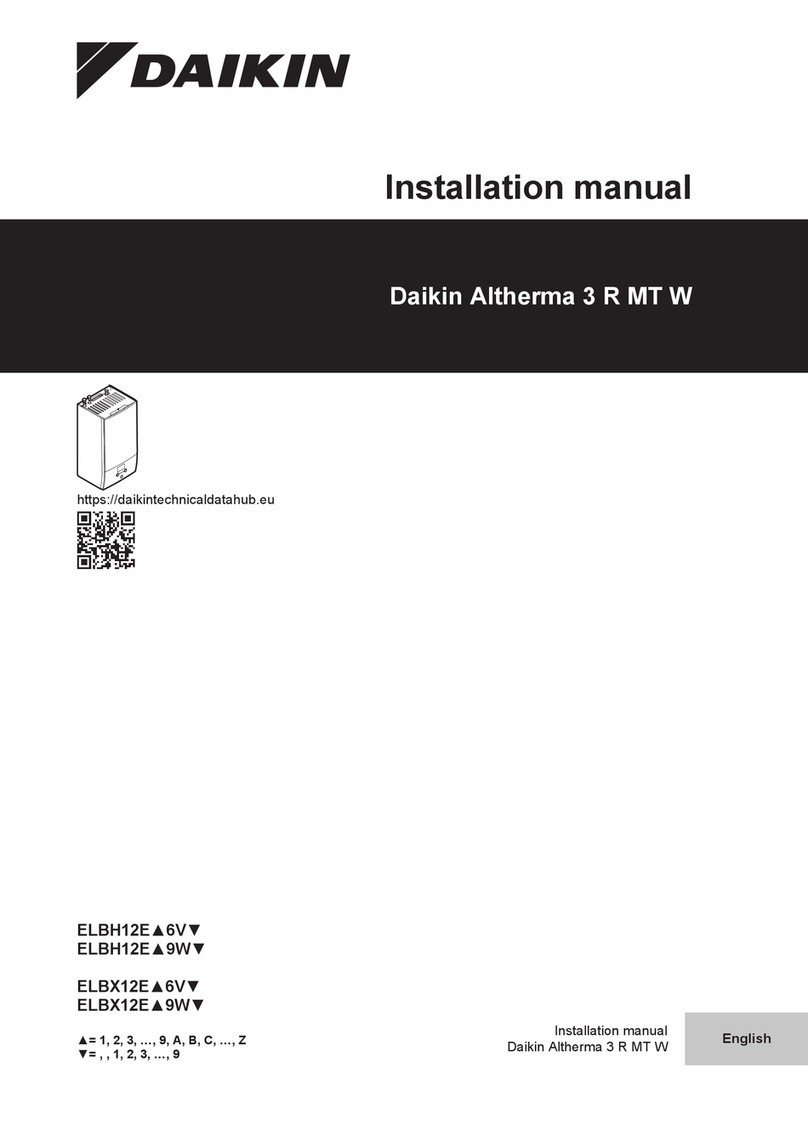

Daikin Altherma 3 R MT W User manual

Daikin

Daikin 2MXS-N Series Dimension Guide

Daikin

Daikin EHYHBH05AA Product information sheet

Daikin

Daikin VRV IV+ Series User manual

Daikin

Daikin Quaternity RXG09HVJU User manual

Daikin

Daikin Altherma 3 GEO EGSAH06UD Series User manual

Daikin

Daikin EWAT016CZN-A1 User manual

Daikin

Daikin VRV III RXYQ5-54PY1 User manual

Daikin

Daikin FVY71LAVE User manual

Daikin

Daikin GYEQ20AN User manual

Daikin

Daikin FNQ25A2VEB User manual

Daikin

Daikin Hubbard GCU2040PXB1 Guide

Daikin

Daikin RMXS-L Series User manual

Popular Heat Pump manuals by other brands

MICROWELL

MICROWELL HP 1000 GREEN Installation and user manual

Sanyo

Sanyo SAP120FCH Service manual

Panasonic

Panasonic WH-SDF03E3E5 Design handbook

Bryant

Bryant 544B Specifications

Airxcel

Airxcel 45000 Series Installation, operation and maintenance instructions

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

Carrier

Carrier WSHP Open v3 Integration guide

TGM

TGM CTV14CN018A Technical manual

Carrier

Carrier 38MGQ Series installation instructions

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Carrier

Carrier 48EZN installation instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet

Bryant

Bryant Preferred Series installation instructions