2)$(.65'6$(1

Table of contents

1This instruction manual ............................................................................. 4

1.1 Precautions..................................................................................... 4

2Safety ....................................................................................................... 5

2.1 Intended use ................................................................................... 5

2.2 Predictable incorrect application ..................................................... 5

2.3 Safe handling.................................................................................. 5

2.4 Staff qualification............................................................................. 6

2.5 Modifications to the product ............................................................ 6

2.6 Usage of spare parts and accessories ............................................ 6

2.7 Liability information ......................................................................... 7

3Product description ................................................................................... 8

4Technical specifications .......................................................................... 10

4.1 Approvals, tests and conformities ................................................. 12

5Transport and storage............................................................................. 12

6Mounting and commissioning.................................................................. 12

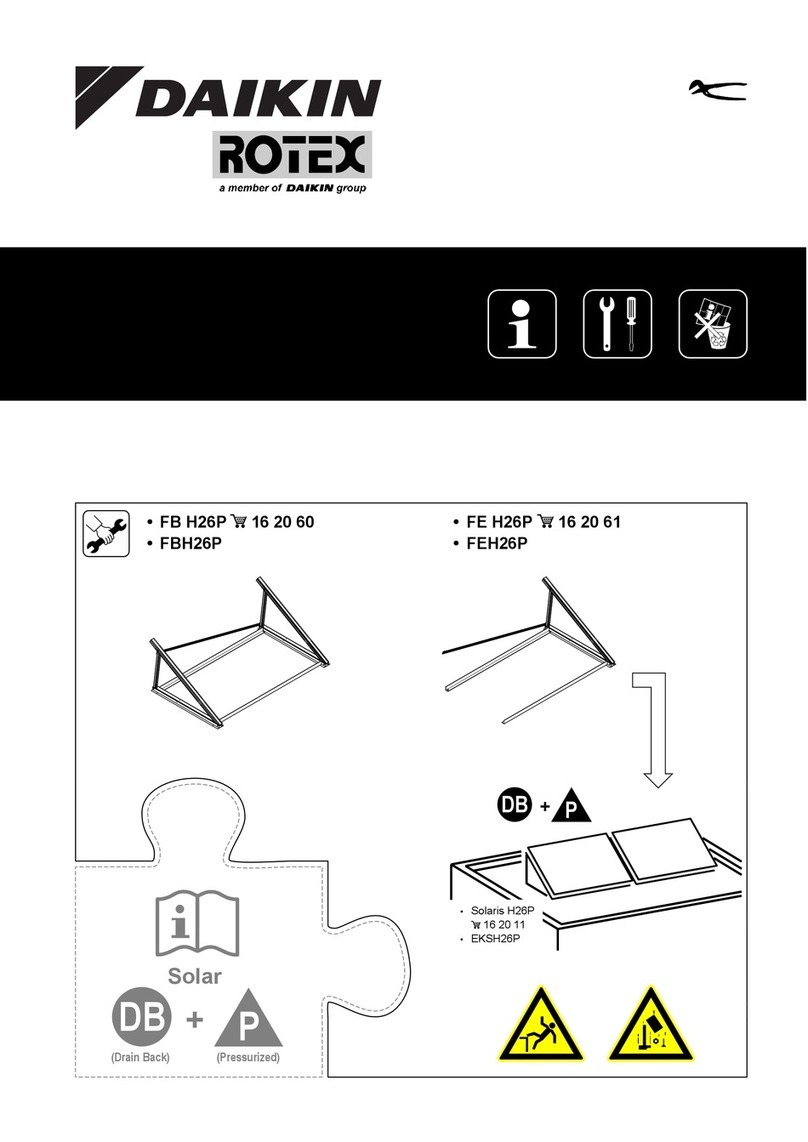

6.1 Mounting (.65'6$ .............................................................. 13

6.2 Connecting (.65'6$ ........................................................... 15

6.3 Electrical connection ..................................................................... 18

6.4 Commissioning (.65'6$..................................................... 18

7Operation................................................................................................ 20

7.1 Reading mark at flow meter .......................................................... 20

7.2 Venting the system ....................................................................... 21