Force 10M /Force 20M6

6 06/10

Section 1.0

1.1 GENERAL INSTRUCTIONS AND DEFINITIONS

This handbook is an integral part of the product; IT MUST be carefully conserved for

future reference.

FOR ANY REQUEST FOR CLARIFICATION, ASK YOUR EMPLOYER OR THE

DAKE TECHNICAL SERVICE, AVOIDING ANY PERSONAL INITIATIVE THAT

COULD CAUSE VERY SERIOUS OR FATAL ACCIDENTS.

Before using the machine, read the warranty carefully.

DEFINITIONS:

-In this manual “right-hand side”, “left-hand side”, “forwards”,

“backwards”, “top” and “bottom” refer to the operator situated in

front of the press with the power unit to his right.

-In this manual, the units of measurement are expressed in the

international system SI (e.g. liquid capacity is expressed in liters).

1.2 DESCRIPTION

The machine described in this manual denominated HYDRAULIC PRESS Model

Dura Press has been specifically designed for use in operations where it is

necessary to use a force of compression that can be moved into different positions

even on the same part:

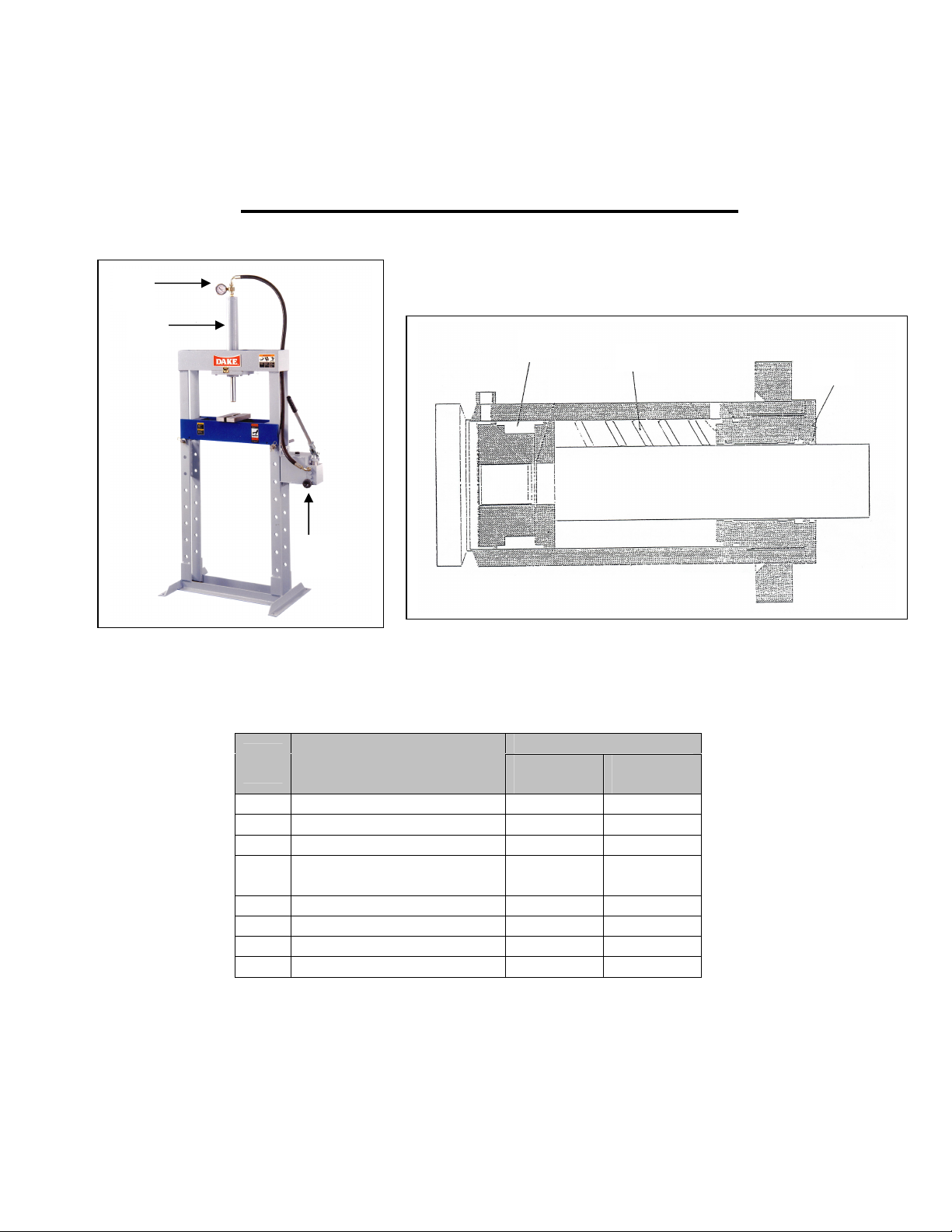

1. The PRESS BODY, made of high tensile carbon steel and thanks to its

monolithic structure, has considerable bending strength.

2. The HAND PUMP, placed on the right of the press allows with facility to reach

the work pressure.

3. The HYDRAULIC CYLINDER specially designed for the specific requirements

of use of the press. In addition to the special care for the internal surfaces

and of the rod, special low-friction gaskets have been used in it to optimize

the operations where special precision in the pressing action is required.

1.3USE

The DURA PRESS/FORCE series press is mainly designed for operations of

straightening out sheet metal, profiles, and metal structures, in addition it can be

used to insert inserts (e.g. bushes, bearings, bushings, etc.), to remove inserts,

calking and all the operations where bending or cutting metal materials are not

carried out.

Other uses are not allowed unless the manufacturer expressly authorizes them.

The substance of the above mentioned operation will always be subordinate to the

maximum working capacity of the press.

THIS MACHINE IS DESTINED ONLY FOR THE USE IT HAS BEEN DESIGNED

FOR, ANY OTHER USE IS TO BE CONSIDERED IMPROPER AND THEREFORE

THE MANUFACTURER CANNOT BE HELD LIABLE FOR ANY DAMAGE

CAUSED BY ANY IMPROPER USE OR USE NOT EXPRESSLY MENTIONED IN

THIS USER’S MANUAL.